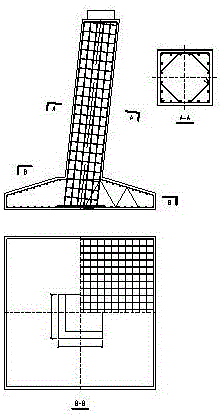

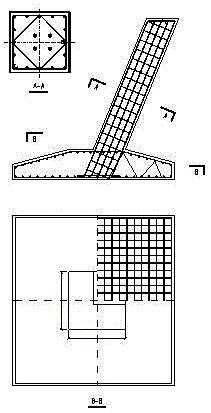

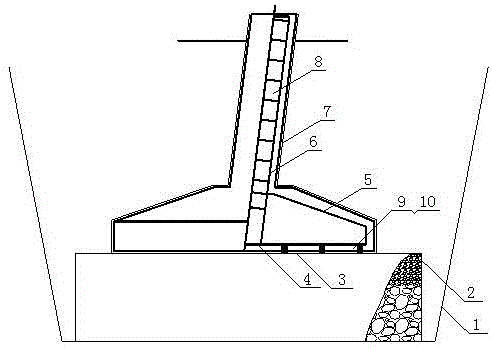

A construction method for inclined column anti-corrosion foundation of transmission lines in salt lake area

A technology for transmission line towers and foundation construction, which is applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of high-quality and high-volume unfavorable engineering, low soil structure strength, and high chloride ion content, and saves the foundation. The amount of concrete material in the body, the improvement of the overall stress condition, and the obvious effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The construction method of the inclined column foundation of the transmission line in the salt lake area of the present invention, its main construction process includes:

[0056] 1 basic positioning

[0057] According to the requirements of the design drawings, use precision measuring instruments and equipment such as levels, theodolites, total stations, vertical balls, and tower rulers to carry out line setting and positioning, and accurately determine the contour line and central axis of the foundation.

[0058] Excavation

[0059] Excavators are used for continuous excavation of the foundation pit. During the excavation process, the exposure time of the foundation pit should be shortened as much as possible and over-excavation is strictly prohibited. The safety status of the foundation pit should be monitored at any time to prevent casualties and injuries caused by the collapse of the foundation pit wall during the excavation process. The equipment is damaged.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com