Laneway repair machine

A technology for repairing machines and roadways, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. It can solve the problems of easy safety accidents, increased construction costs, and low construction efficiency. Increase construction safety, reduce labor intensity, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

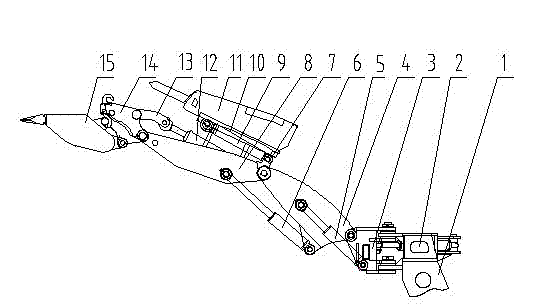

[0014] exist figure 1 Among them, the roadway repair machine includes a gantry 1, a rotary cylinder 2, a boom seat 3, a boom 4, a boom cylinder 5, a small arm cylinder 6, a slider or a roller 7, a small arm 8, a breaking hammer cylinder 9, Chute 10, breaking hammer 11, bucket oil cylinder 12, connecting rod mechanism 13, quick connector 14 and bucket or hydraulic shear 15, gantry 1 is fixed with the frame or transport trough, and the boom seat 3 is connected with the gantry connected, the front end of the boom base is hinged with one end of the boom 4 through a pin, the other end of the boom is hinged with one end of the forearm 8 through a pin, and the rodless end and the rod end of the forearm cylinder 6 are respectively passed through a pin It is hinged with the boom and the forearm, the two ends of the boom cylinder 5 are respectively hinged with the boom seat and the boom through the pin shaft, the two ends of the bucket cylinder 12 are respectively hinged with the forear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com