Crankshaft provided with main journal and rod journal

A connecting rod journal and crankshaft technology, applied in the crankshaft field, can solve problems such as high manufacturing costs, achieve the effects of reducing pressure concentration, reducing weight and risk of cracks, and reducing stress on parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

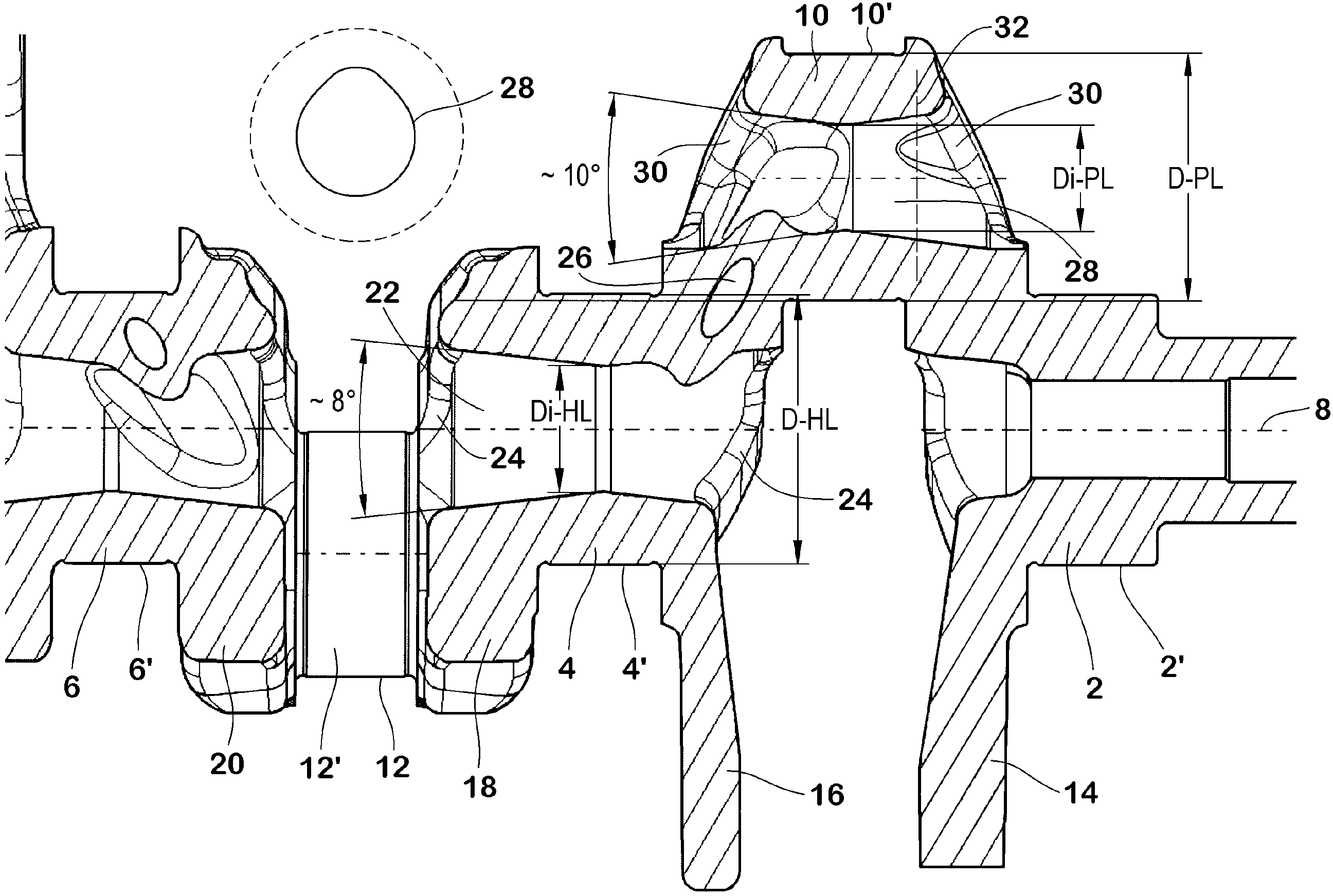

[0017] The crankshaft shown contains main journals 2, 4, 6... which are arranged axially at equal distances along the center axis 8 and which each have a cylindrical main bearing surface 2', 4' on their outer sides , 6'....

[0018] Between two adjacent main journals 2 , 4 , 6 . . . there are respectively connecting rod journals 10 , 12 . The connecting rod bearing surfaces 10', 12'.

[0019] Each connecting rod journal 10, 12 is connected to the adjacent main journal 2, 4, 6... by means of a crank arm 14, 16, 18, 20....

[0020] Only the axial section of the crankshaft containing the main journal 4 , the pin pin 10 and the associated crank arms 14 , 16 and 18 will be described in detail below. The other main and pin journals of the crankshaft are of the same or similar design.

[0021] The main journal 4 has an axial through-hole 22 which, starting from its narrowest point, widens conically both in the direction of its outlet to the crank arm 16 and in the direction of its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com