Design method for bolt flange connecting structure of homogeneous gasket

A technology for connecting structures and bolted flanges, which is applied in flange connections, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the problems of ignoring the influence of sealing performance and not fully considering the mechanical and sealing characteristics of connected structural elements. , to achieve the effect of reducing the design workload, avoiding casualties and material and financial losses, and accurately designing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

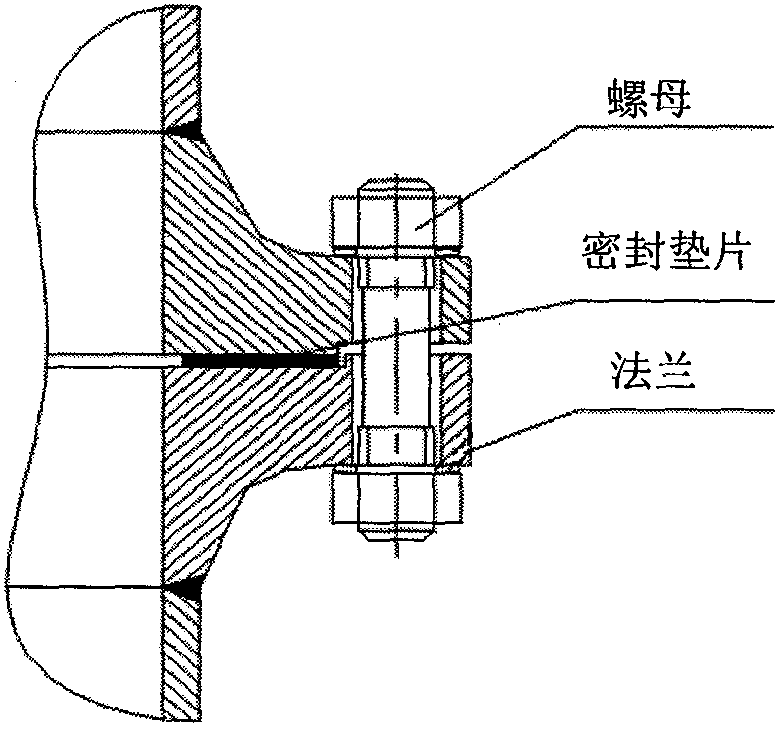

[0041] A pipe is flanged, the inner diameter of the pipe is 200mm, the working pressure is 2.0MPa, the working temperature is 20°C, the internal medium is hydrogen, the connection structure does not bear the action of external bending moment, and the allowable leakage rate is 2×10 -3 cm 3 / (s mm), design a bolted flange connection.

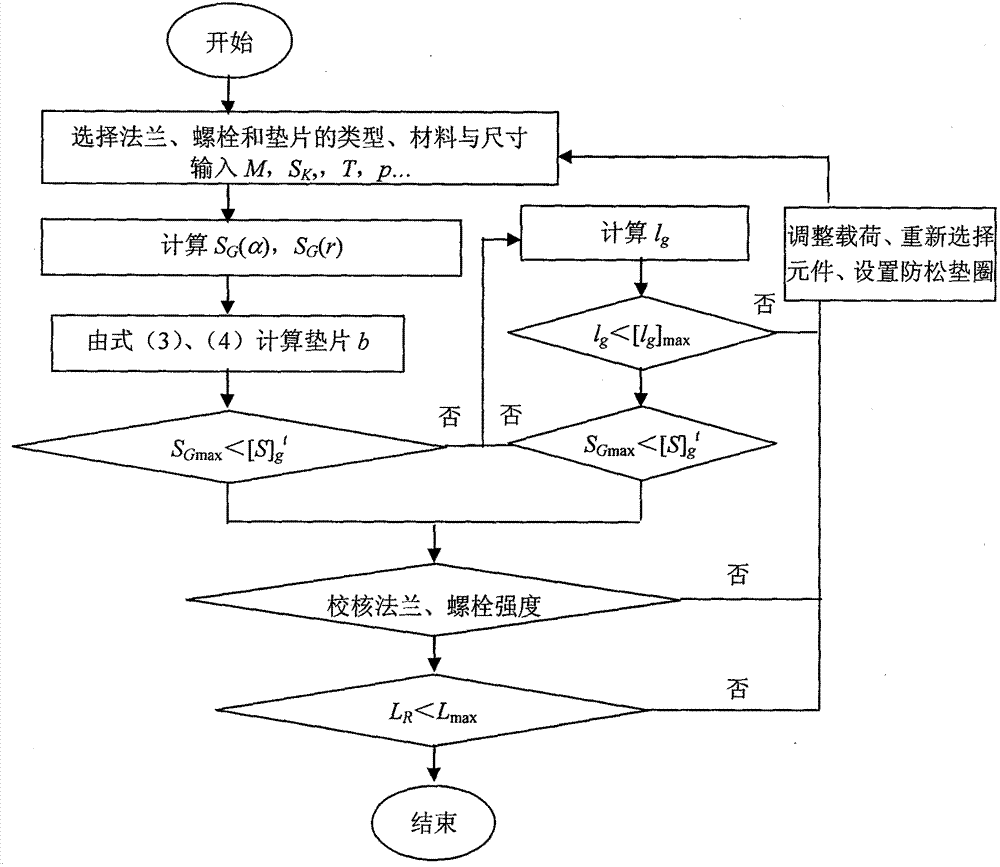

[0042] The design process is as follows.

[0043] ①According to the on-site working conditions and the pipe diameter, PN2.5, DN200 raised-face welded steel pipe flanges are initially selected for the flange, which conforms to the GB / T 9115.1-2000 standard, and the material is 20# steel; 12 M24 bolts are used , stud bolts made of 35CrMo, gaskets made of asbestos rubber sheet gaskets, the size is According to the standard calculation, the preload of each bolt is 206kN.

[0044] ② When the connection structure does not bear external bending moment, the maximum stress S of the gasket is obtained from the deformation coordination equation Gmax is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com