A backlight module

A technology of backlight module and back cover, which is applied in the direction of light source, electric light source, light source fixing, etc., can solve the problems of increasing the cost of liquid crystal display, widening and reducing the overall thickness of liquid crystal display, and achieving the goal of reducing thickness, height and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

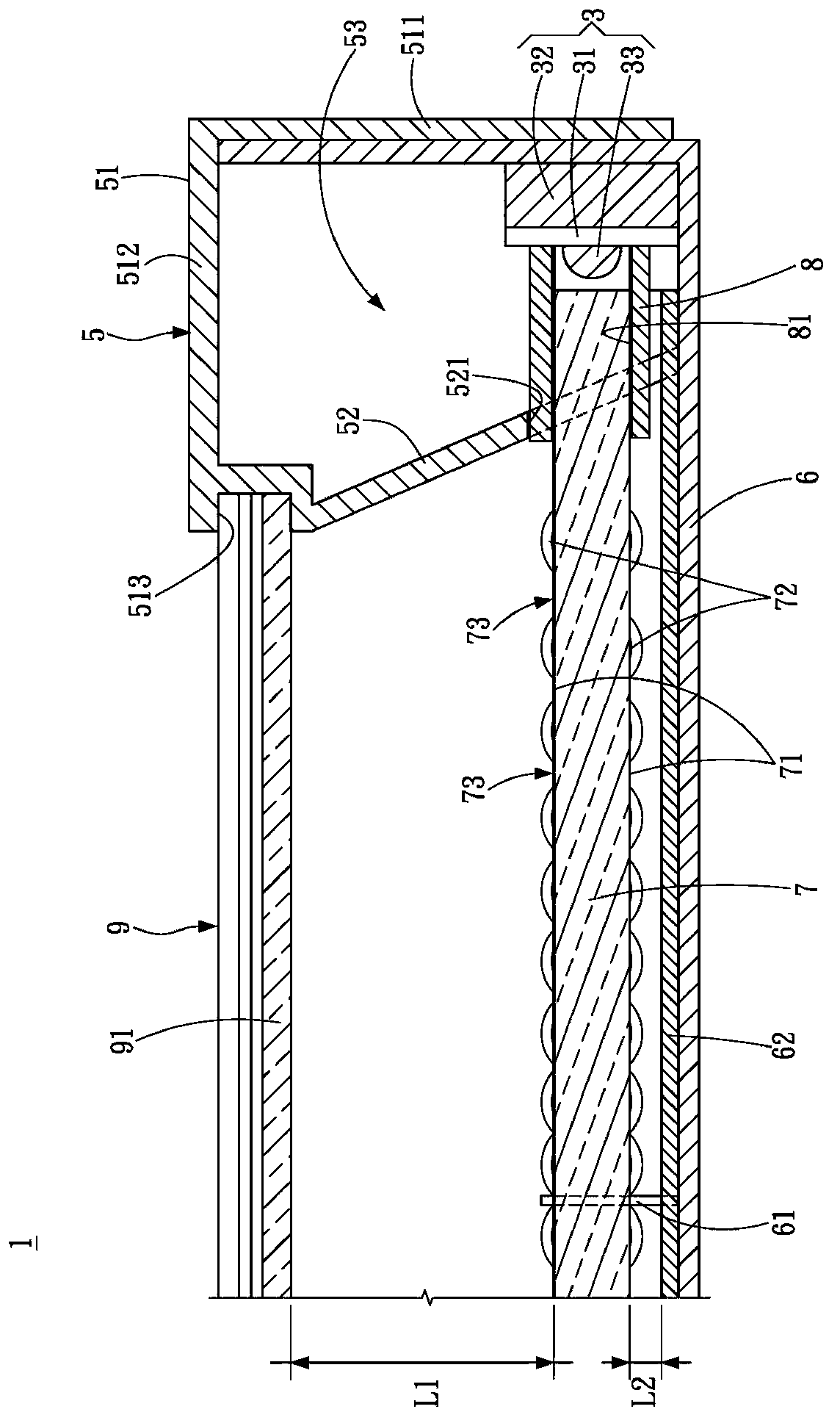

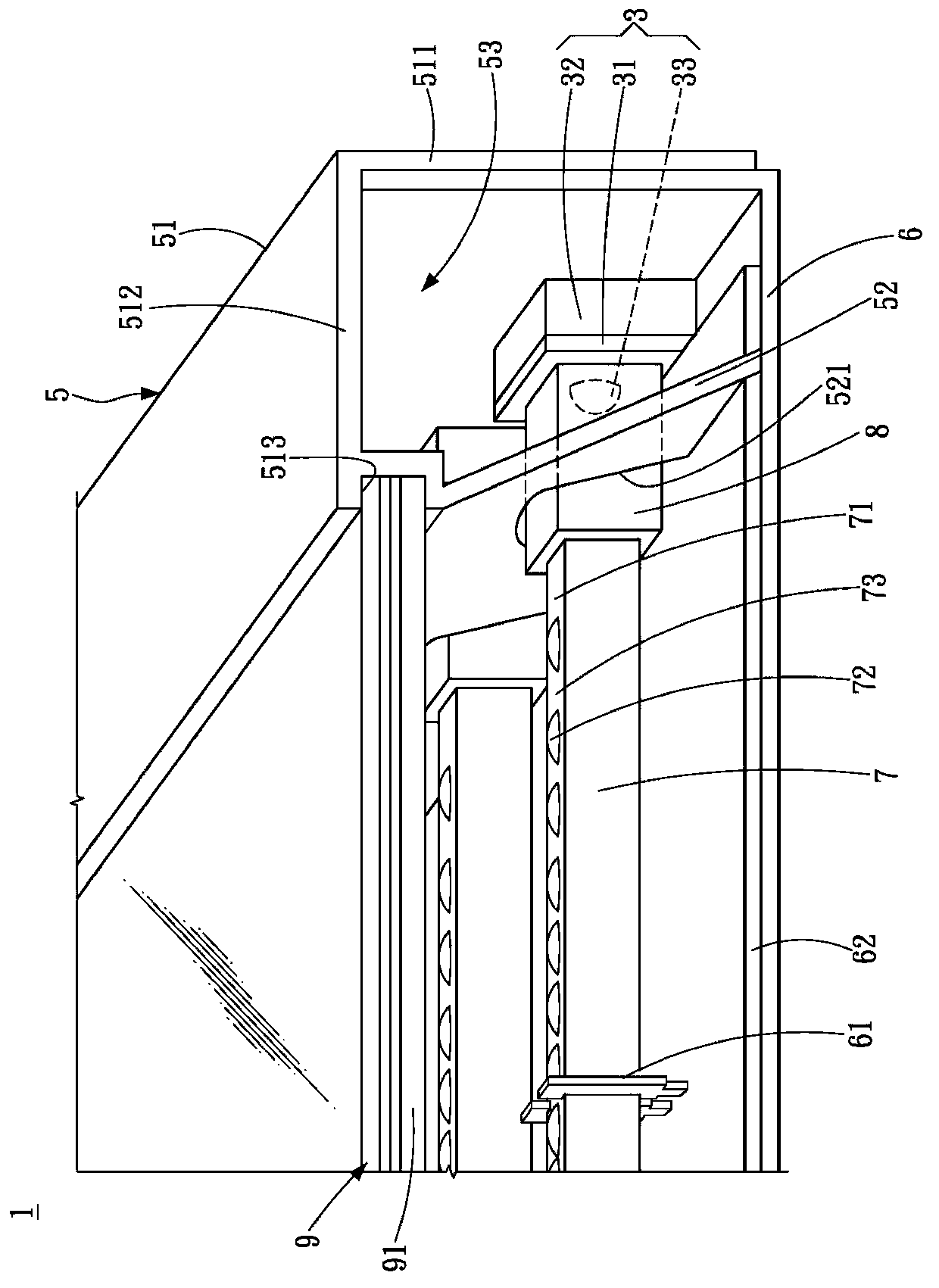

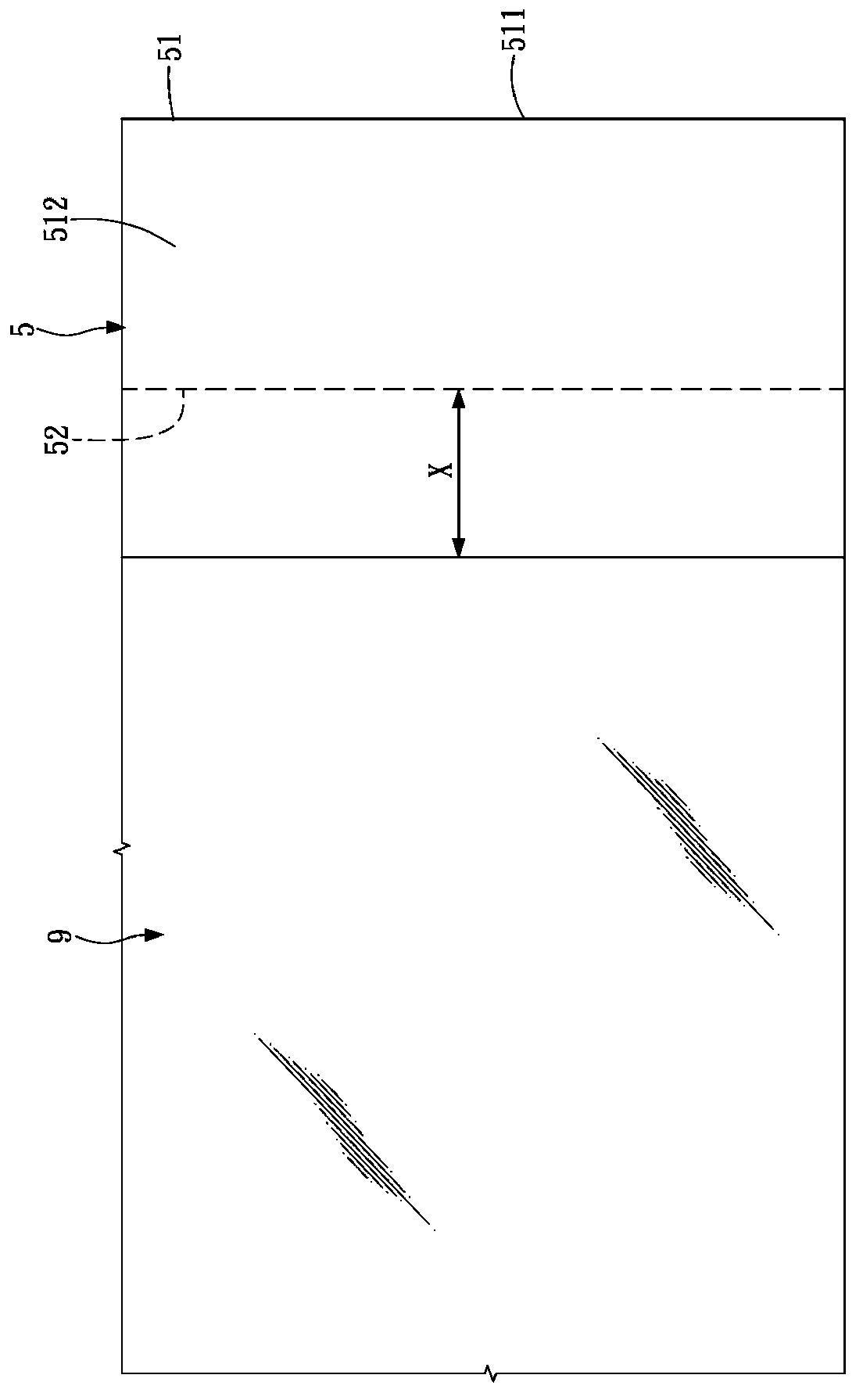

[0052] see figure 1 , figure 2 and image 3 , the first embodiment of the present invention. figure 1 is a partial cross-sectional schematic diagram, figure 2 is a schematic diagram of the local appearance, image 3 It is a partial top view schematic diagram.

[0053] Such as figure 1 and figure 2 As shown, the backlight module 1 in the first embodiment of the present invention includes: a plurality of light source modules 3 , a frame 5 and a plurality of light guide rods 7 .

[0054] The light source module 3 can be mainly composed of a substrate 31, a support seat 32 and a light emitting element 33, wherein the light emitting element 33 is welded on the substrate 31, the substrate 31 is positioned on the support seat 32, and the support seat 32 can be selected to have a high thermal conductivity The heat dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com