Spherical feedback tricomponent fluxgate magnetic full-tenser gradiometer

A three-component, fluxgate technology, applied in the field of geophysical exploration devices, can solve problems such as large system errors, difficult to eliminate, feedback coil interference, etc., to achieve the effects of easy calibration, reducing baseline distance, and avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment for further detailed description:

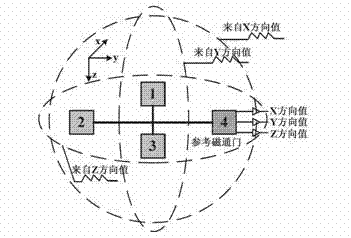

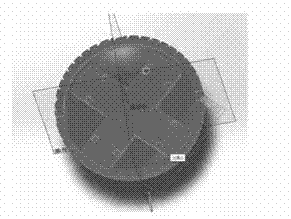

[0022] The spherical feedback three-component fluxgate magnetic gradient full tensor probe is engraved on the surface of the spherical non-conductive material with enameled wire winding grooves of equal width, different depth and equal spacing distributed in three directions parallel to the Cartesian coordinate system; There are more than three three-component fluxgate sensors inside, and the three-component fluxgate sensors are fixed on the cross-shaped bracket inside the sphere by bolts, and the control circuit is installed outside the sphere, and the three-component fluxgate sensors are connected to the three-axis spherical ball The feedback coil forms a closed loop to form a three-component fluxgate magnetic gradient full tensor probe.

[0023] The distribution of three-component fluxgate sensors in the sphere is that the first three-component fluxgate sensor 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com