Three-phase mechanical link connecting mechanism of breaker

A connection mechanism and circuit breaker technology, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problem of inconvenient assembly of the crank arm, and achieve the effect of compact structure, small volume and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

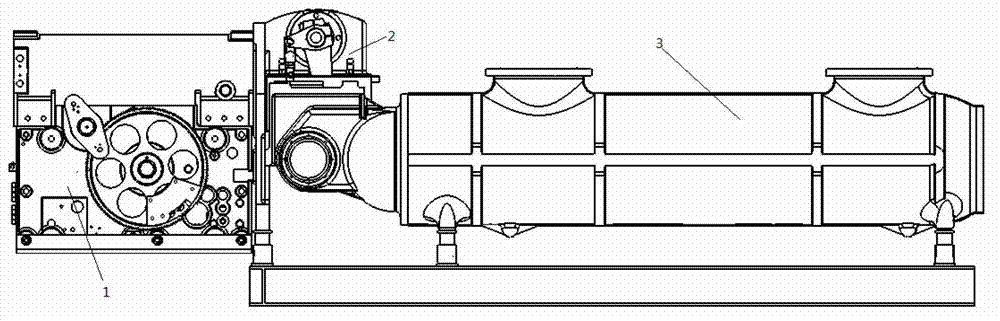

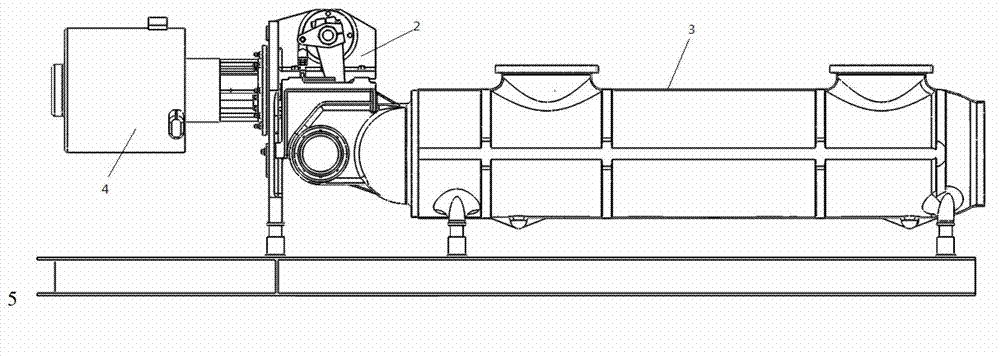

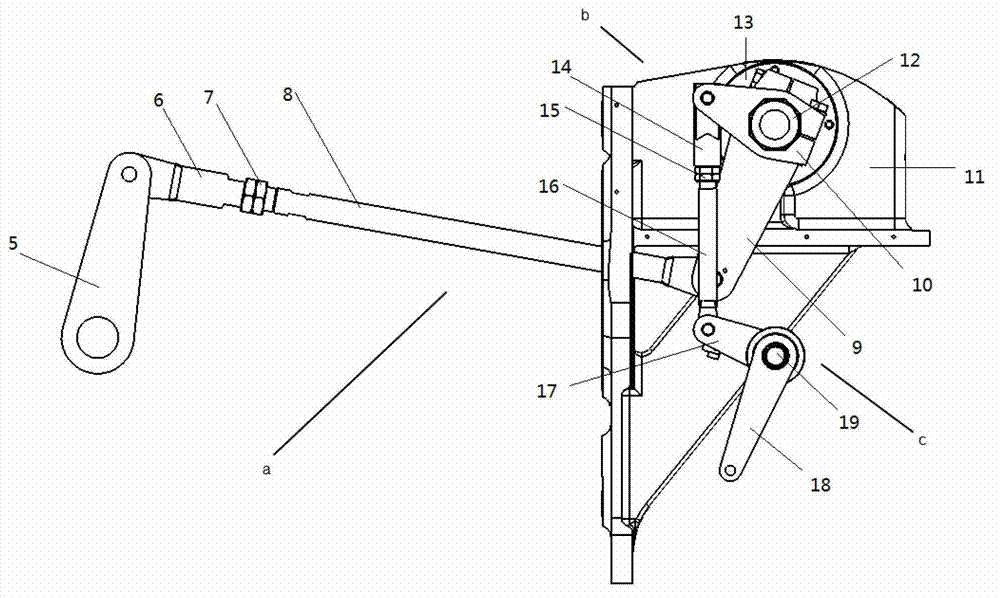

[0028] Such as Figure 1-a and Figure 1-b As shown, this embodiment includes: a drive link mechanism a, a bracket assembly b and a single connecting link mechanism c, wherein: the input end of the drive link mechanism a and the operating mechanism (such as the spring mechanism 1 in Figure 1a or Figure 1b The output ends of the hydraulic spring mechanism 4) are connected, and the output ends are jointly rotated with the input ends of the single-connected rod mechanism c and are arranged on the bracket component b. The output ends of the three single-connected rod mechanisms c are respectively connected to the three-phase circuit breaker The three corresponding input ends of the circuit breaker are connected, and the torque output by the operating mechanism is output to the crank arm shaft 19 of the three single-link mechanism c through the drive linkage mechanism a, and through the inner crank arm 18, insulation in the circuit breaker body Parts such as tie rods and metal tie ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com