Crushing repair method for compensation straight line of main pole of DC motor

A technology of DC motors and repair methods, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., and can solve problems such as long repair time of motors, scrapped main poles, and poor tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

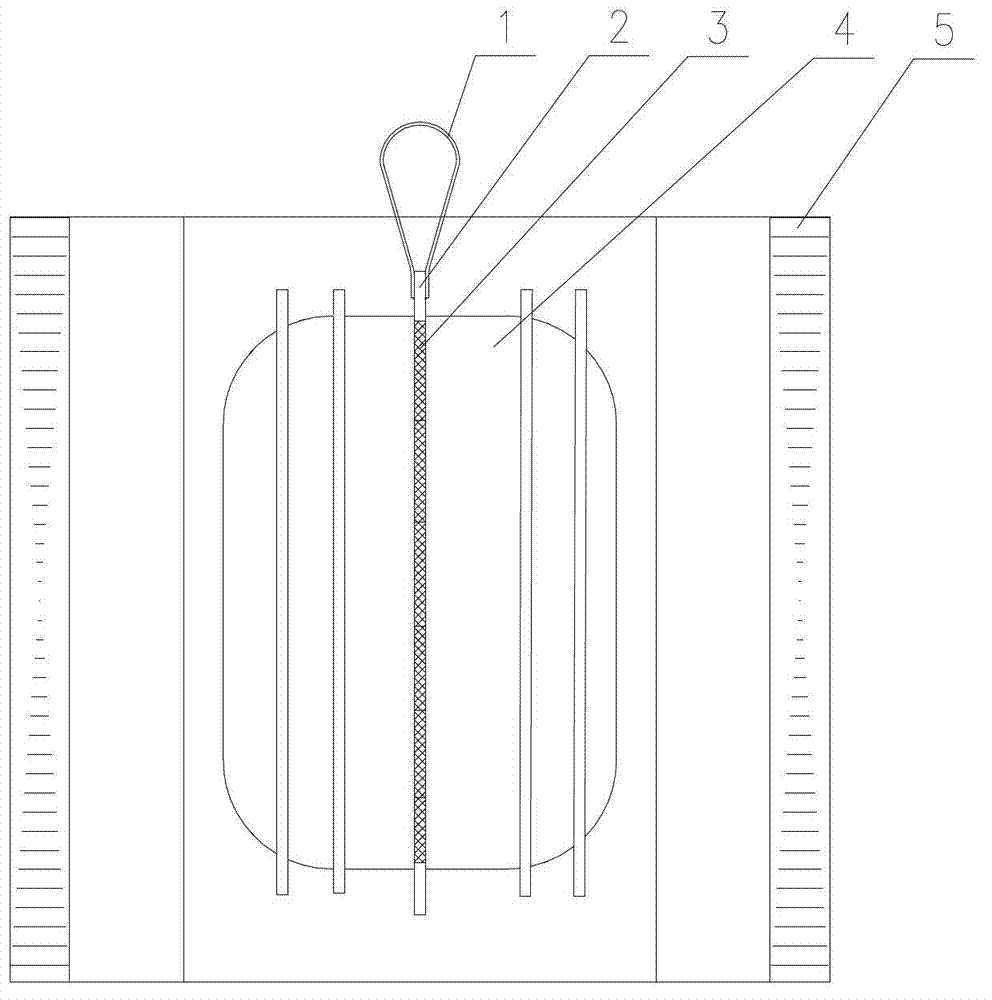

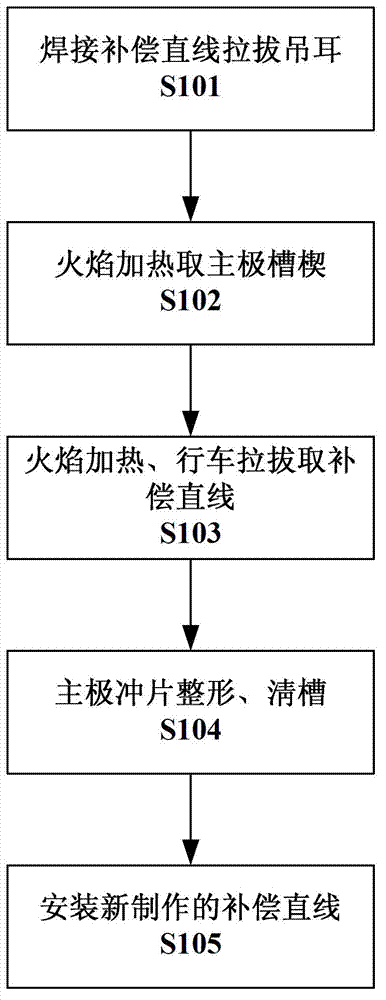

[0017] combine figure 1 schematic diagram and figure 2 First, in step S101, install the main pole where the pressure breaking compensation line 2 is located on the machine base 5, and weld a copper lifting lug 1 to the end of the breaking pressure compensation line 2, and the welding must be firm. Then, in step S102, the slot wedge 3 on the compensation straight line 2 is heated until the slot wedge 3 is loosened, and the slot wedge 3 is removed while it is hot. Next, in step S103, two welding torches are used to heat the compensation line 2. When heating, pay attention to moving up and down evenly so that the insulation of the compensation line 2 is heated evenly until the insulation is carbonized. The compensation line 2 is hoisted by driving, and the jog button must be used to operate the driving to avoid lifting. If the speed is too fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com