A Standing Wave Linear Ultrasonic Motor

A linear ultrasonic motor and standing wave technology, which is applied to generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of standing wave linear ultrasonic motors that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

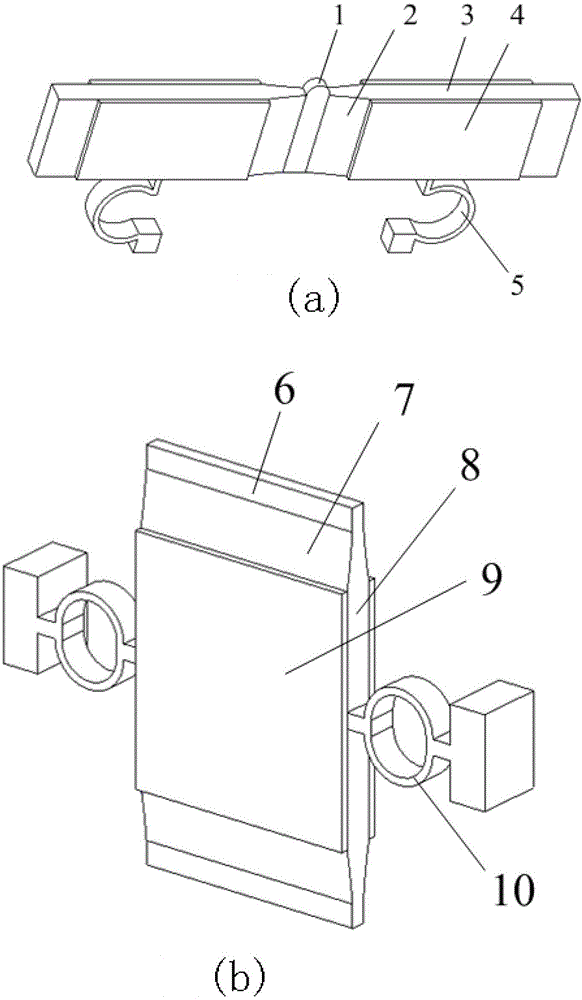

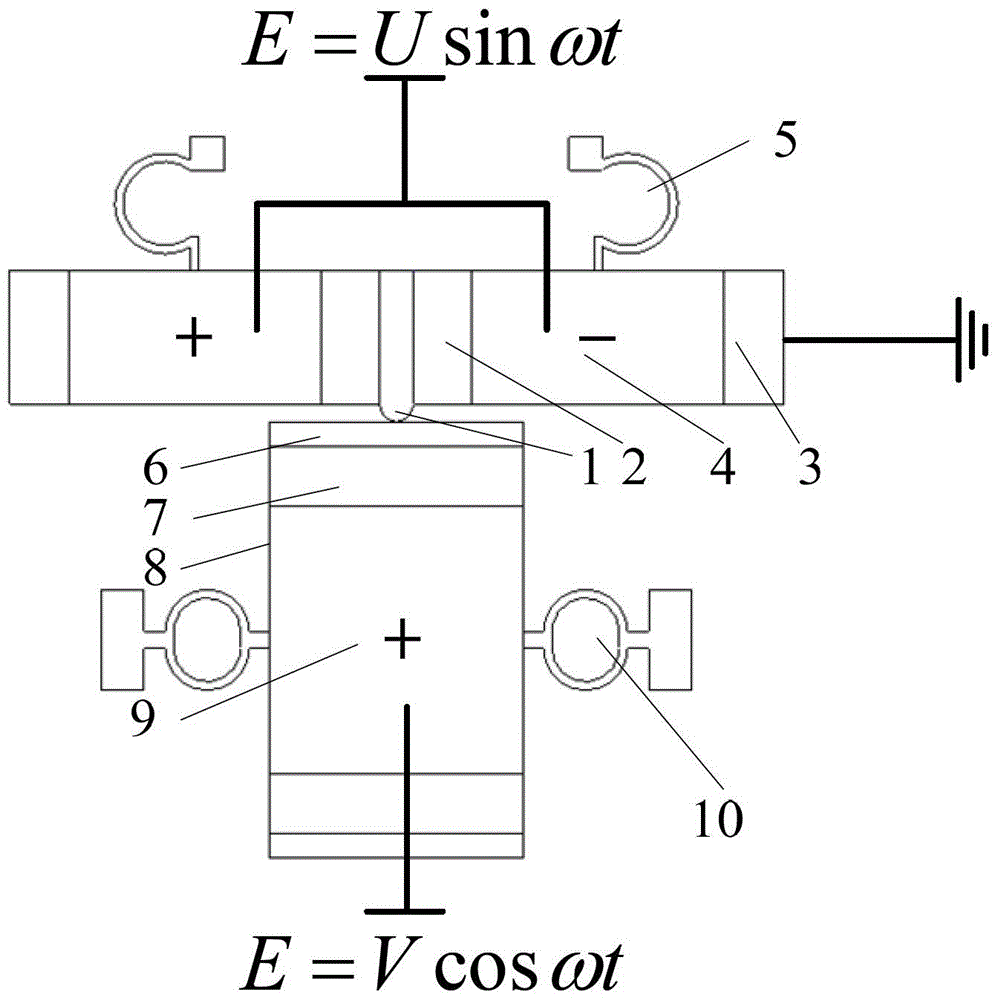

[0018] A standing wave type linear ultrasonic motor of the present embodiment is as figure 1 , 2As shown, including a stator and a mover, the stator and the mover are standing wave piezoelectric vibrators, the number of the stator is one, the number of the mover is one, and the driving foot of the stator is connected to the mover One of the driving surfaces of the stator interacts, the stator is fixed on the base, and the mover is fixed on the guide rail, and at the same time, the stator and mover interact to drive the mover to move; the stator is controlled by the first The piezoelectric ceramic sheet is composed of a first metal elastic body, the first metal elastic body includes a driving foot, a first continuously variable cross section part, and a first constant cross section part, and the driving foot is located between two first continuously variable cross section parts, The first constant cross-section part is set outside the first continuously variable cross-section ...

Embodiment 2

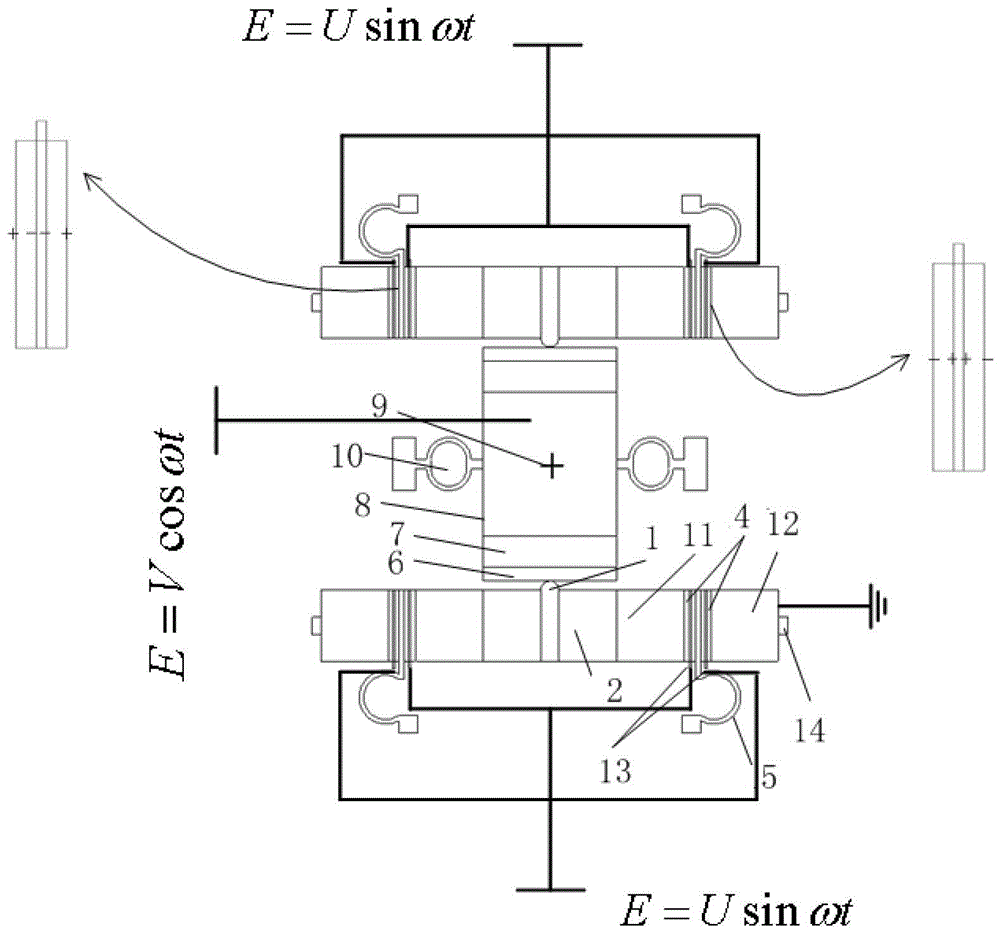

[0023] The difference between this embodiment and embodiment 1 is: as image 3 As shown, the number of the mover is one, the number of the stator is two, the driving foot of one of the stators interacts with one driving surface of the mover, and the other driving surface interacts with the other The driving feet of one stator interact, and at the same time, there are two first piezoelectric ceramic sheets on the same side of any one stator, and an electrode sheet is arranged between the two first piezoelectric ceramic sheets on the same side, and The outer sides of the two first piezoelectric ceramic sheets on the same side are respectively provided with a front counterweight and a rear counterweight, and the stator is also provided with pre-tightening bolts; a sinusoidal electric field is applied to the first piezoelectric ceramic sheet to excite its action. In the second-order longitudinal vibration, a tangential alternating force is generated at the contact between the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com