Microencapsulated oils for controlling pesticide spray drift

一种微囊化、杀虫剂的技术,应用在杀生剂、微胶囊制剂、应用等方向,能够解决高分子量水溶性聚合物不能完全令人满意、除草剂容器混合物使用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

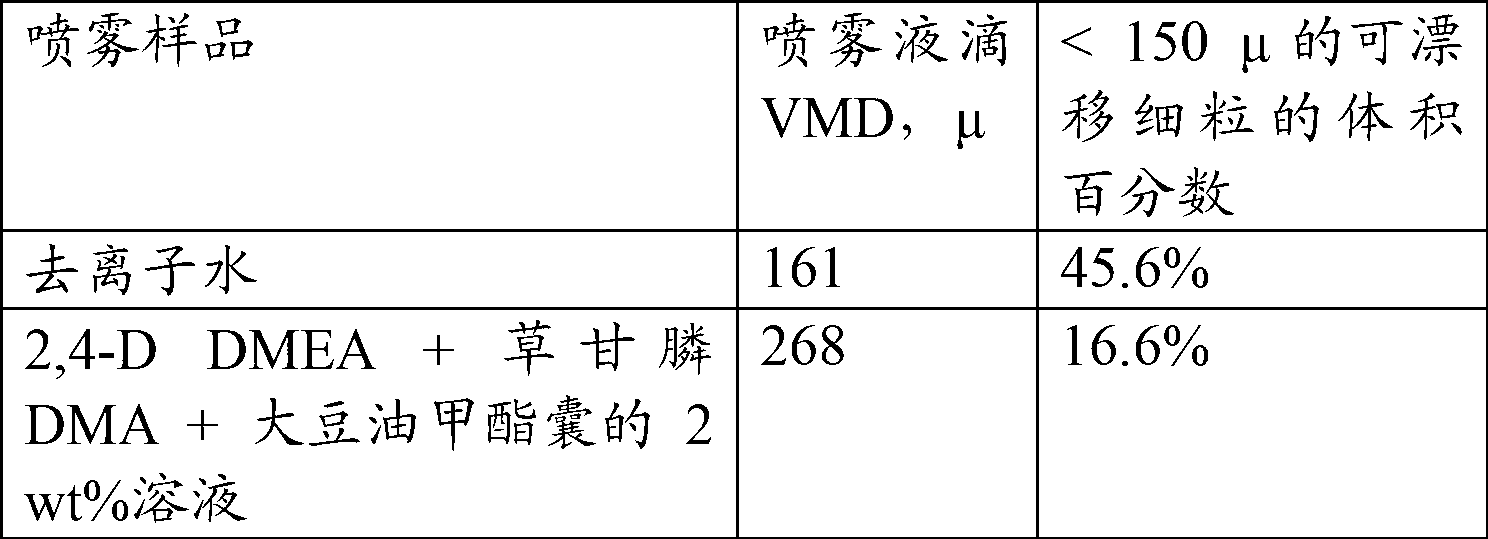

Embodiment 1

[0029] Using a Silverson homogenizer, will contain 132.68g soybean oil methyl ester (methyl soyate) and 13.95g 27 The organic phase of diphenylmethane diisocyanate (registered trademark of Dow Chemical Company) was emulsified to contain 30.0 g 4913 polymeric surfactant (registered trademark of Croda Inc.), 7.50 g 15-S-7 nonionic surfactant (registered trademark of Dow Chemical Company), 0.39 g GXL preservative (registered trademark of Arch Chemicals Inc.) and 112.13 g deionized water in the aqueous phase. The resulting crude emulsion was passed through a Niro high pressure homogenizer twice at 800-1200 bar (80,000-120,000 kPa). Polyurea capsule walls were then formed by adding 3.33 g of a 10% aqueous solution of ethylenediamine with gentle stirring. The resulting capsule suspension had a volume median particle size of 0.34[mu] as measured using a Malvern Mastersizer 2000 Laser Diffraction Particle Analyzer.

[0030] To 3.68 g of the above methyl soybean oil sac suspens...

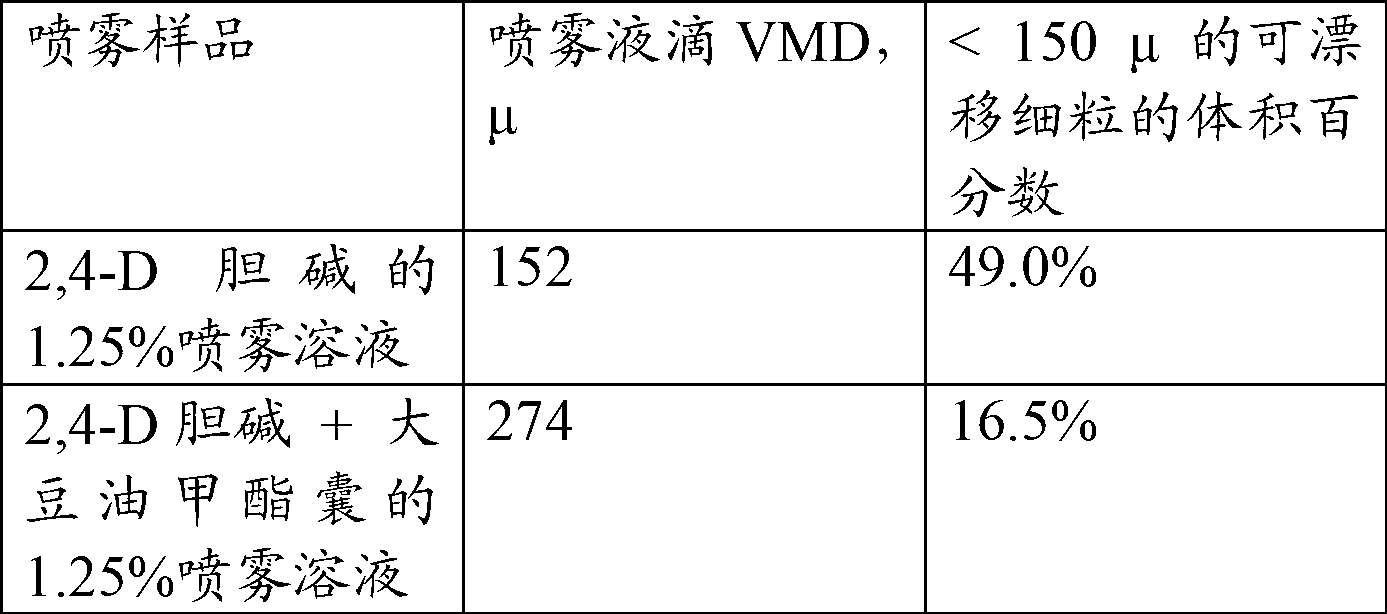

Embodiment 2

[0035] Using a Silverson homogenizer, will contain 340.53g soybean oil methyl ester and 9.05g The organic phase of 27 (registered trademark of Dow Chemical Company) was emulsified to contain 96.0 g 4913 (registered trademark of Croda Inc.), 24.0 g 15-S-7 (registered trademark of Dow Chemical Company), 1.20 g GXL (registered trademark of Arch Chemicals Inc.) and 358.8 g of deionized water in the aqueous phase. Increase the speed on the homogenizer until the volume median droplet size is approximately 0.8 μ. Polyurea capsule walls were then formed by adding 21.73 g of a 10% aqueous solution of ethylenediamine with gentle stirring. The resulting capsule suspension had a volume median particle size of 0.72[mu].

[0036] A herbicide concentrate comprising 456 g ae / L 2,4-D choline salt and 10 wt % of the above soybean oil methyl ester microcapsule suspension was prepared as follows: 39.91 g 45.7% ae 2,4-D choline was added to the vial Solution (prepared by mixing equimolar ...

Embodiment 3

[0041]Contrast adding and not adding the soybean oil methyl ester sac suspension prepared in embodiment 2 containing ammonium sulfate (AMS) Spray performance of 280SL herbicide (registered trademark of Bayer CropScience; 2.34 lbae / gal glufosinate-ammonium). To the vial was added sequentially 284.33 g deionized water, 15.03 g 40% w / w ammonium sulfate in water and 3.97 g 280SL. Shake the vial by hand until homogeneous. To prepare the capsule-containing spray solution, to a second vial was added sequentially 283.57 g deionized water, 15.03 g 40% w / w aqueous ammonium sulfate, 3.97 g 280SL and 0.76 g of the soybean oil methyl ester capsule suspension prepared in Example 2. Shake the second vial by hand until homogeneous. The solution was then sprayed following the same procedure and settings as described in Example 1. The results are shown in Table 3.

[0042] table 3

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com