Automatic sewing machine and technology using same

A sewing machine and craft technology, applied to sewing machine components, program-controlled sewing machines, sewing equipment, etc., can solve the problems of high labor intensity, increased production costs, difficult processing, etc., and achieve the effect of improving sewing efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

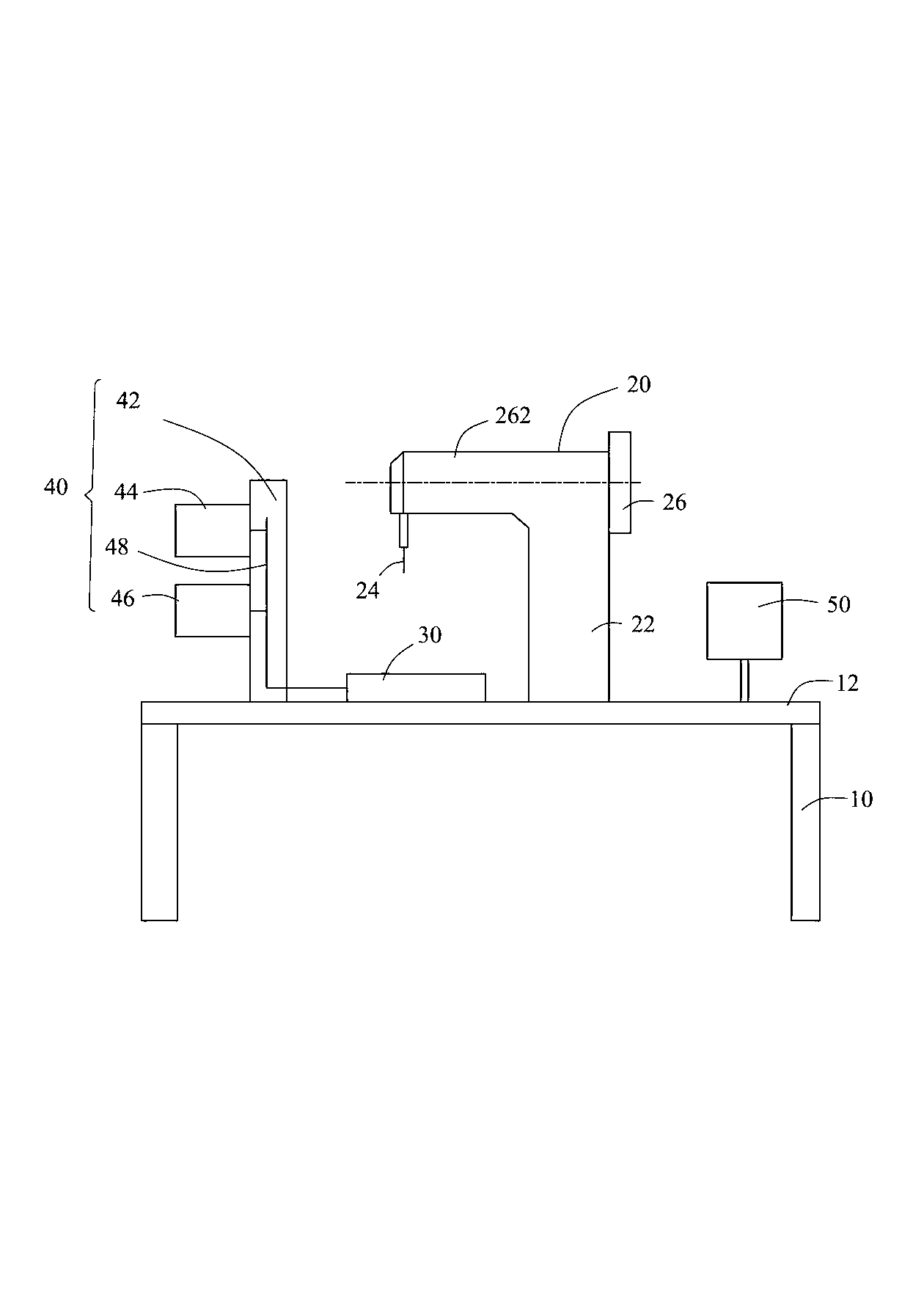

[0016] see figure 1 , the automatic sewing machine 100 of the preferred embodiment of the present invention includes a machine base 10 , a sewing machine body 20 , a press plate 30 , a press plate adjustment mechanism 40 , and an electric control system 50 .

[0017] The machine base 10 includes a working table 12 , on which the sewing machine body 20 , a pressing plate 30 , a pressing plate adjusting mechanism 40 and an electric control system 50 are carried and assembled.

[0018] The sewing machine body 20 includes a main frame 22 , a sewing needle 24 and a first motor 26 mounted on the main frame 22 . The main body frame 22 is a structure used in a traditional sewing machine, and utilizes the action principle of a crank connecting rod and a crank slider to realize the up and down reciprocating movement of the sewing needle 24 . The main frame 22 is provided with a main shaft 262 connected to the first motor 26 and other transmission mechanical components (not shown). Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com