Well Completion Technology of Radiation Well in Sand and Pebble Formation

A technology for radiation wells and sand and pebble, which is applied in the field of well formation technology of radiation wells, and can solve the problems of large resistance of the water filter pipe, the influence of the water filter pipe on the water output of the radiation well, and the difficulty of drilling holes in drilling rigs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

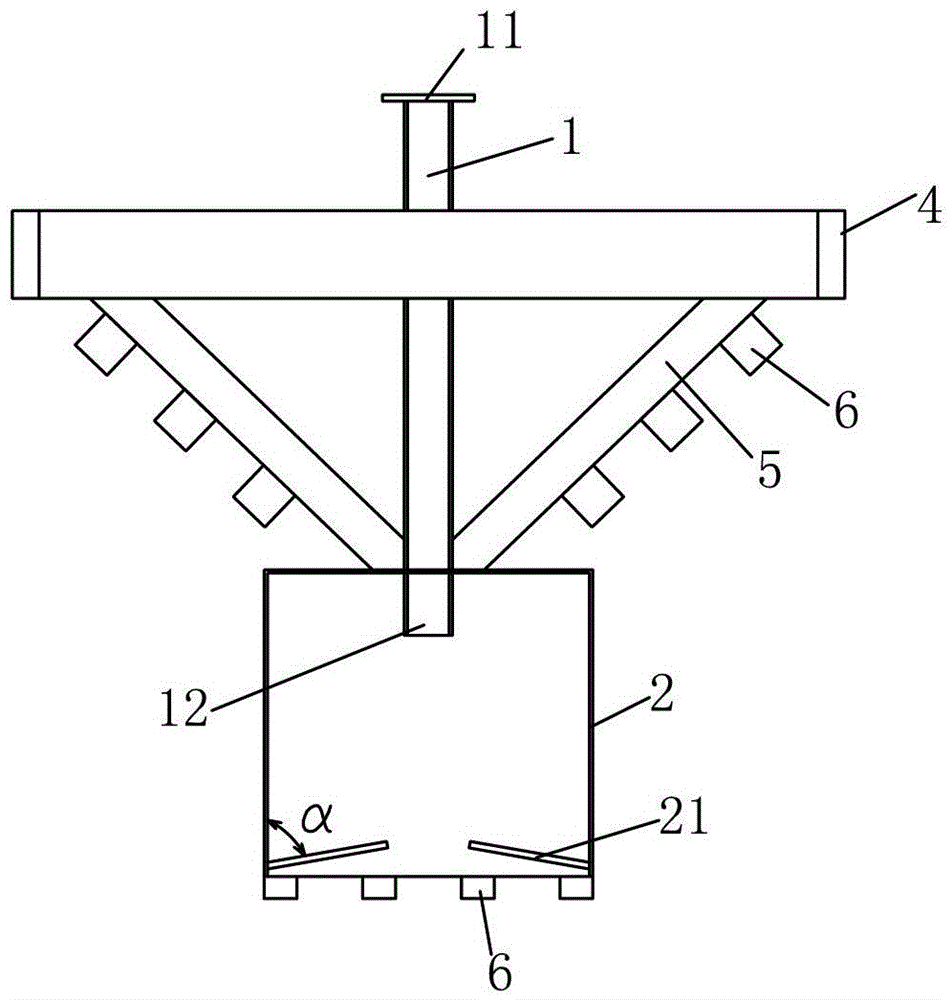

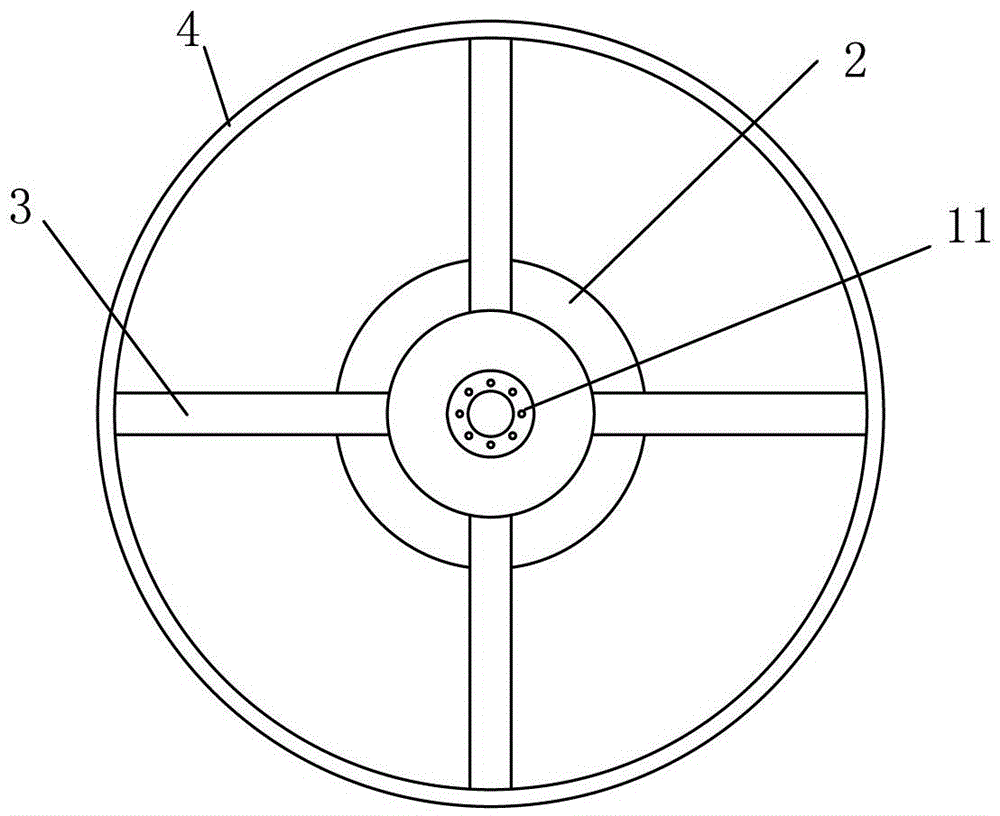

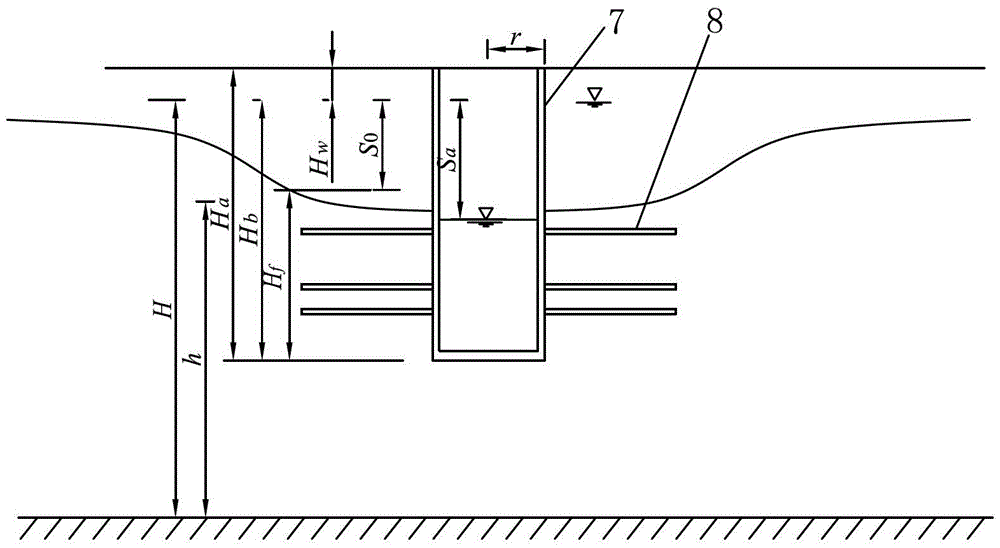

[0067] The well-forming process of the radiation well in the sand and pebble formation of the present invention comprises the following steps:

[0068] 1) Shaft construction

[0069] The reverse circulation rotary drilling rig is used to form holes. The inner diameter of the drill pipe of the rotary drilling rig is not less than 180mm, and the sand and gravel mud pump is not less than 8 inches. figure 1 , 2 As shown, it includes a water inlet pipe 1, the upper end of the water inlet pipe 1 is integrally formed with a drill pipe flange 11, and the lower end is welded with a stone fishing bucket 2, which is a barrel body with a closed upper end and an open lower end, and the end of the water inlet pipe 1 extends into In the stone fishing bucket 2, a φ25mm steel wire rope 21 is anchored on the inner wall of the opening end of the stone fishing bucket 2. The length of the steel wire rope 21 is smaller than the radius of the inner wall of the stone fishing bucket 2. A plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com