Ultralong hollow spiral grouting anchor rod connection piece

A technology for grouting bolts and connectors, which is applied in the installation of bolts, mining equipment, and earth-moving drilling, etc., can solve problems such as the length limit of bolts, and achieve the effect of high reliability and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

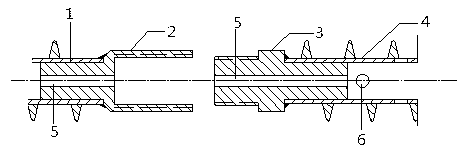

[0009] As shown in the figure, the front end rod body 1 of the anchor rod is welded to the front end connector 2, and the tail end anchor rod body 3 is welded to the end end connector 4, and the center of the front end connector 1 and the end end connector 3 are drilled with a grouting hole 5. An overflow hole 6 is left at the end of the rod body 4 at the tail end of the anchor rod.

[0010] When in use, the two connecting pieces are installed together through a threaded connection to form an ultra-long grouting bolt, and then installed in the coal tunnel anchor hole, and the ultra-long bolt high-pressure grouting operation can be implemented after sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com