Artificial neural network based method for controlling online prediction of casting billet quality

An artificial neural network, casting billet technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of inability to comprehensively evaluate the surface quality of products, quantitative description parameters and limited types of defects, and achieve operation. The effect of simple and guaranteed prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the examples, but the present invention is not limited.

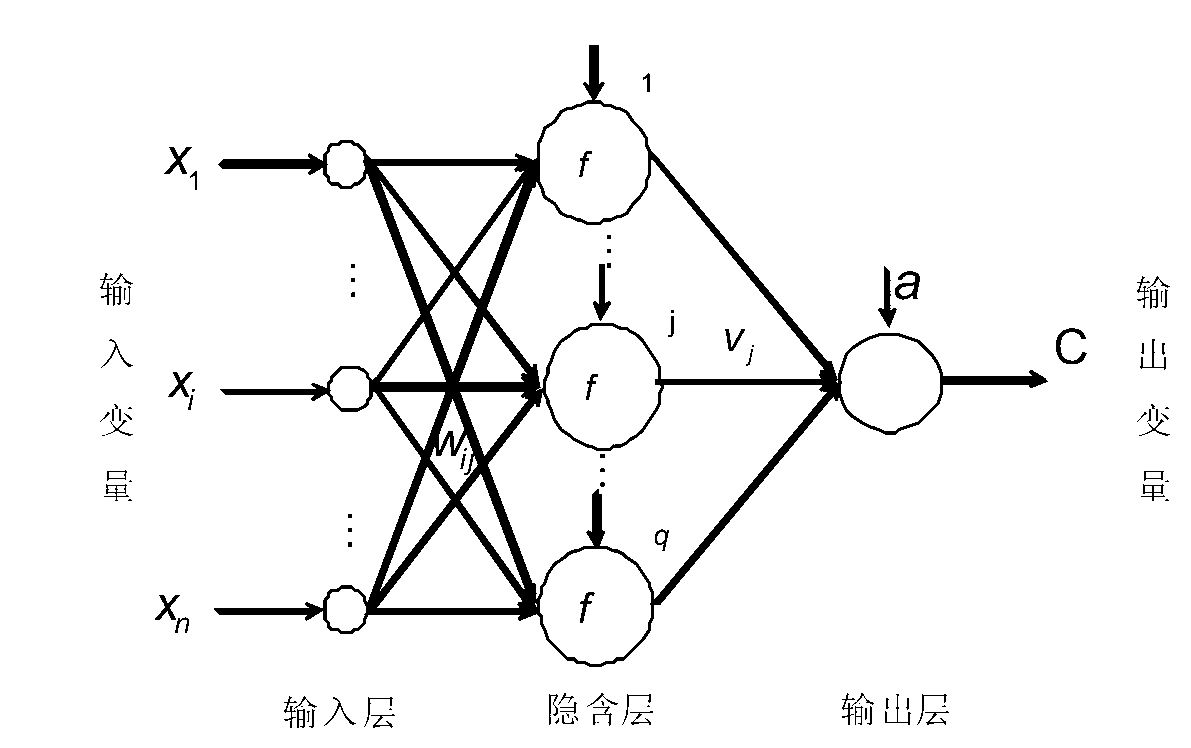

[0038] The structure of the three-layer BP neural network model is as follows: figure 1 shown. The structure of the three-layer BP network model is as follows: n input neurons in the input layer represent n main process and equipment parameters that affect quality defects, q hidden neurons in the middle layer or hidden layer, and 1 output neuron in the output layer It represents a certain quality defect level of the research object of slab defect.

[0039] Step 1: First select the predictive model variables and initially build the model:

[0040] Establish a three-layer BP neural network model consisting of input layer, hidden layer, and output layer; the parameters are described as follows:

[0041] Network input variable P k =(x 1 , x 2 ,...,x n ); network target variable T k =y; Hidden layer unit input variable S k =(s 1 ,s 2 ,....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com