A method to improve the capture rate of underetched defects

A technology for insufficient etching and defects, which is applied in the field of scanning defects, can solve the problems of reducing defect capture rate, indistinguishability, copper can not be exposed for a long time, etc., and achieve the effect of shortening the development cycle and improving the capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be explained in detail below in conjunction with the accompanying drawings.

[0023] The method for improving the capture rate of insufficient etching defects according to the embodiment of the present invention includes the following steps:

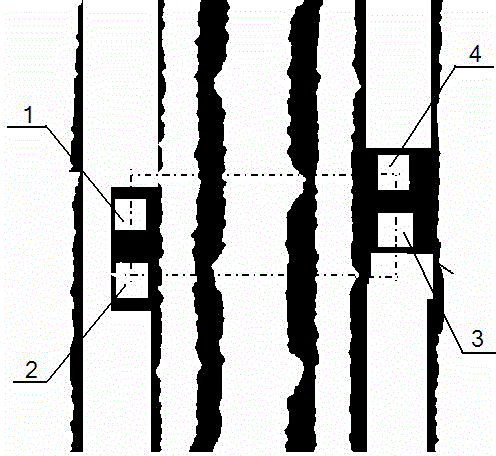

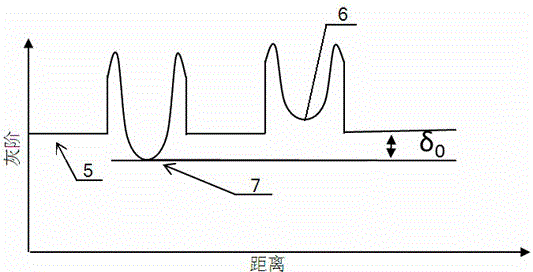

[0024] First, after the etching of the wafer and before the planarization of the copper connection holes, an electron beam defect scanner is used to establish a scanning program with appropriate conditions to scan the normal contrast copper connection holes and the under-etched copper connection holes of the wafer.

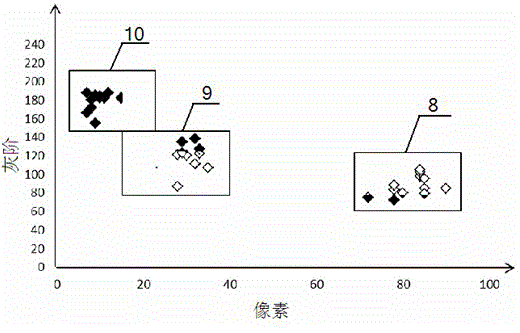

[0025] Next includes step 1 and step 2, such as image 3 As shown in , scan the pixel size and gray scale of the comparative copper connection hole, connection hole edge and background of the wafer, and determine the background area 8, the contrast copper connection hole area 9 and the connection hole edge area 10 from large to small pixels; And establish a two-dimensional distribution map ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com