Patents

Literature

30results about How to "Improve crawl rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

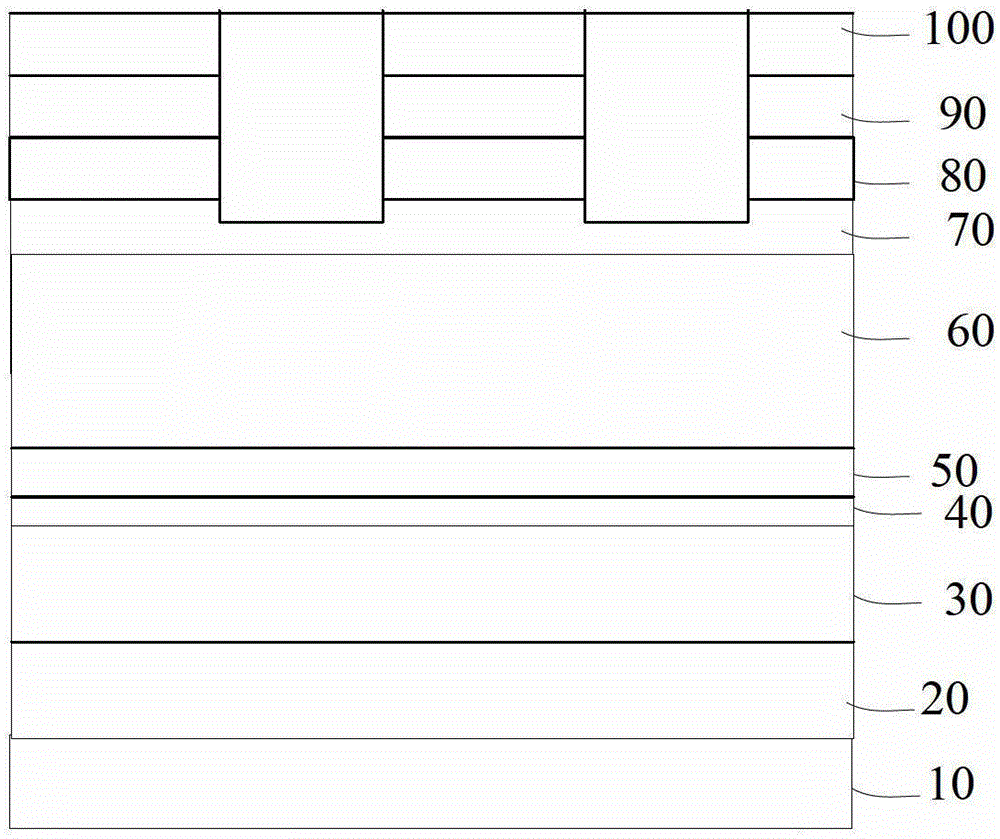

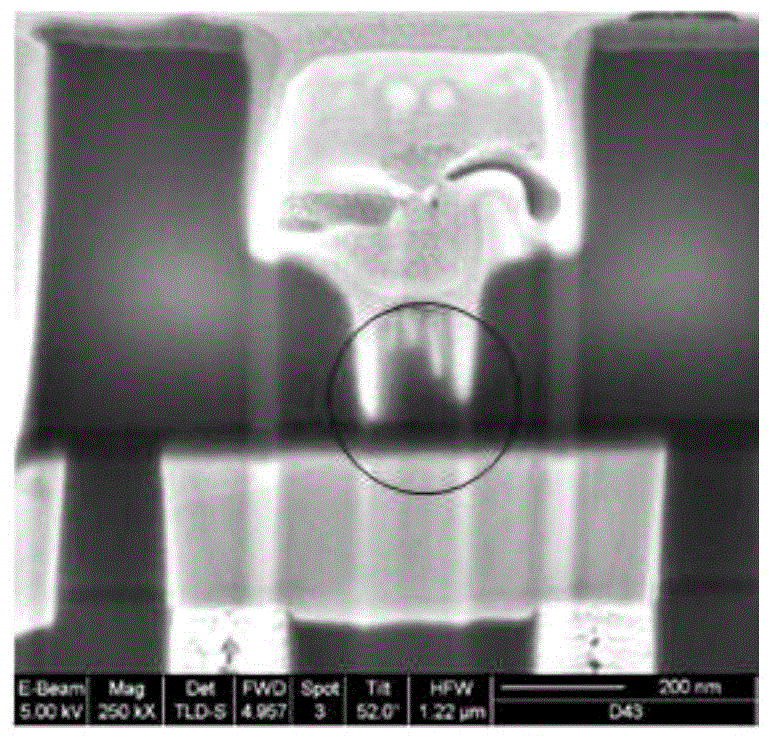

Method for detecting under-etching and deficiency defect of through hole

ActiveCN103367192AImprove crawl rateImprove yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetal silicideSilicon oxide

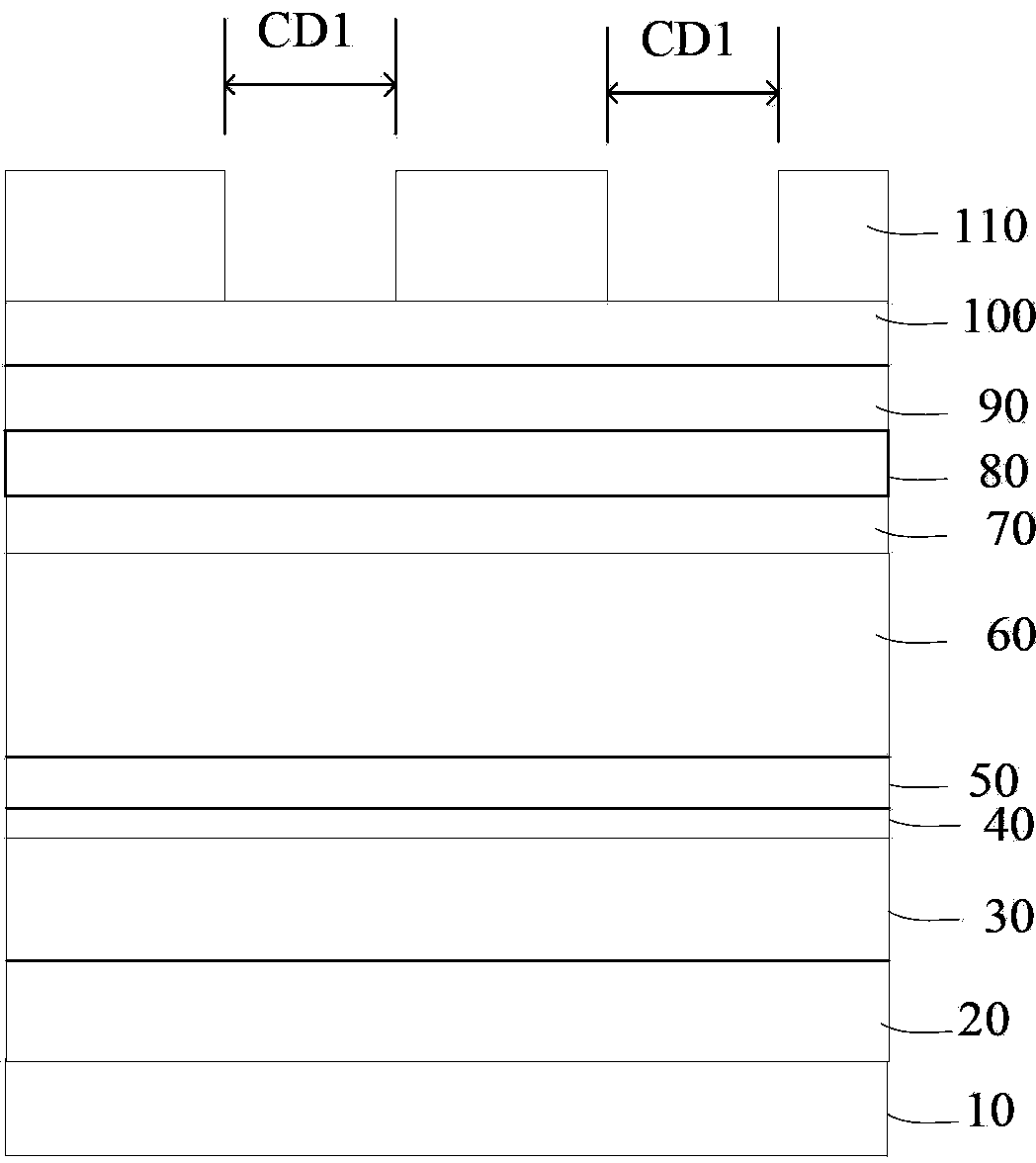

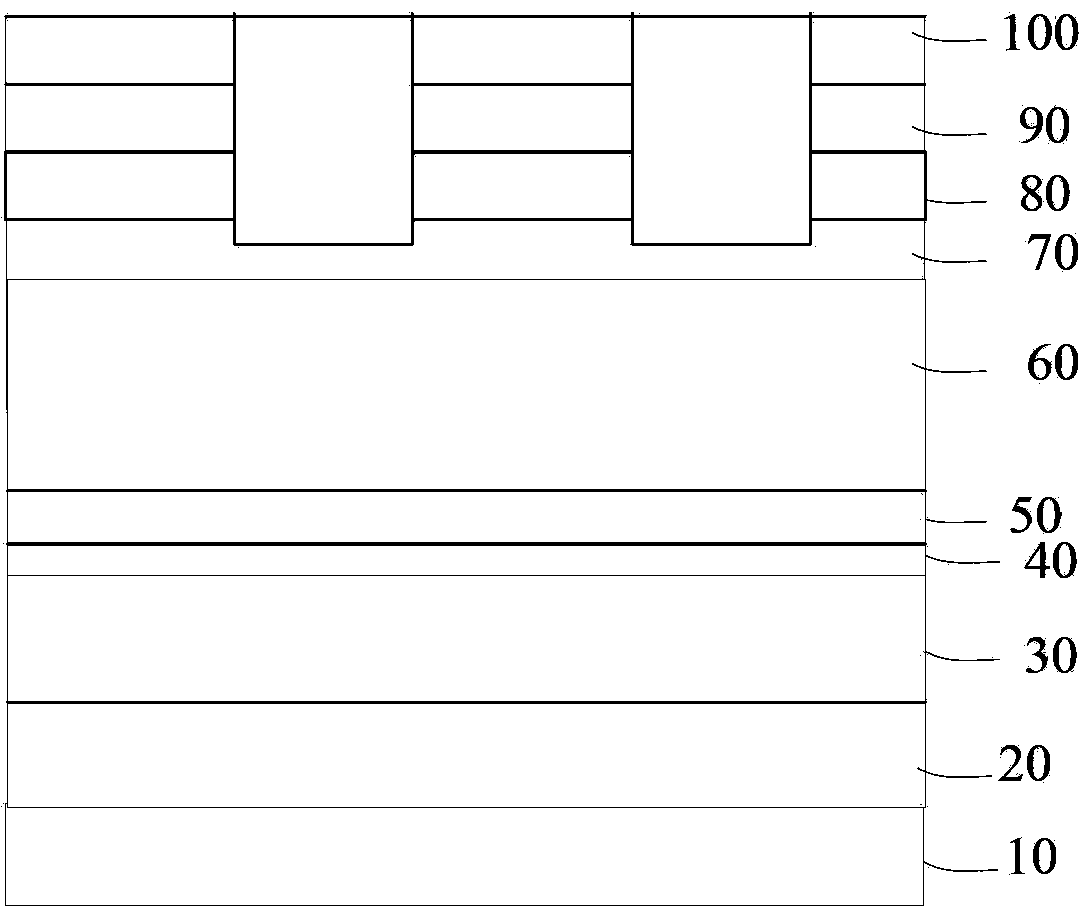

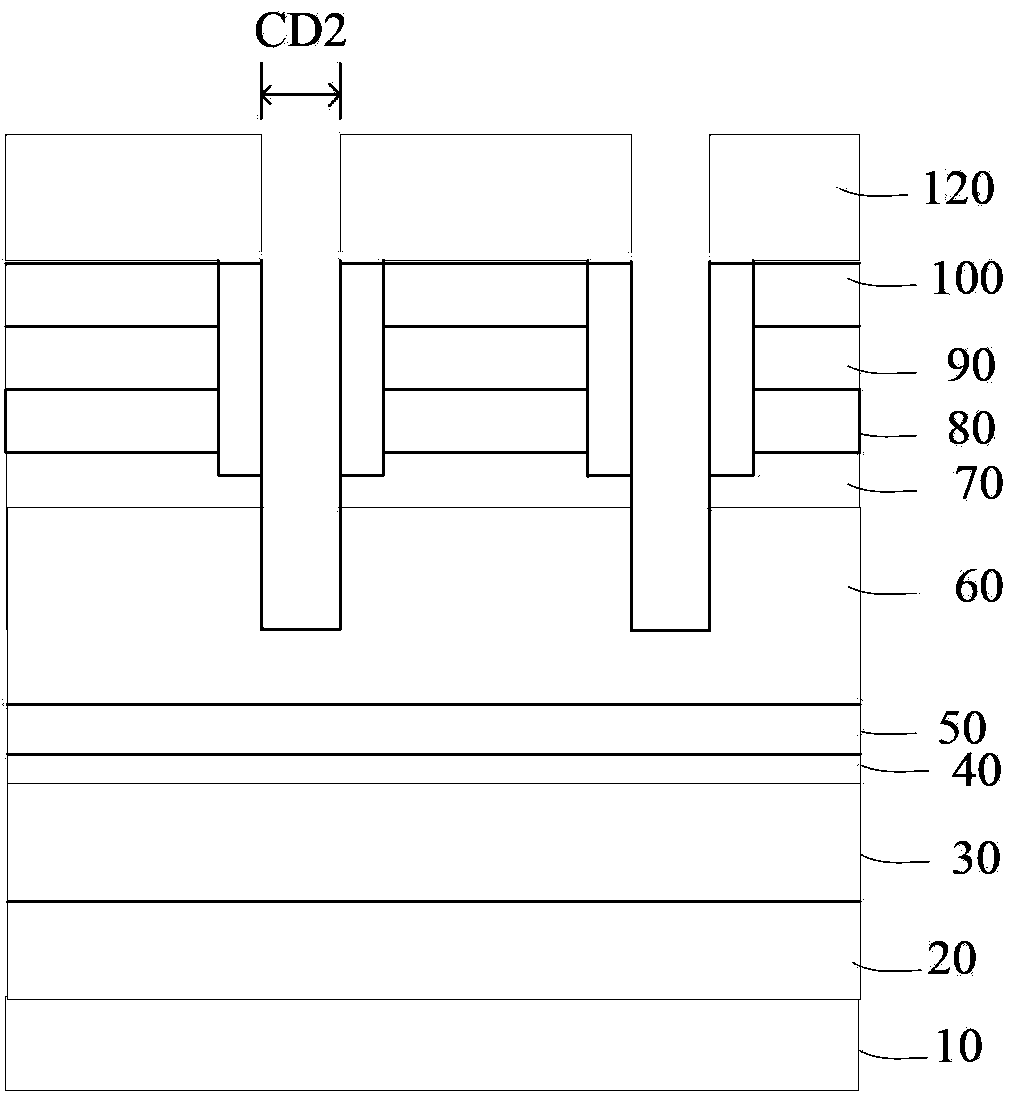

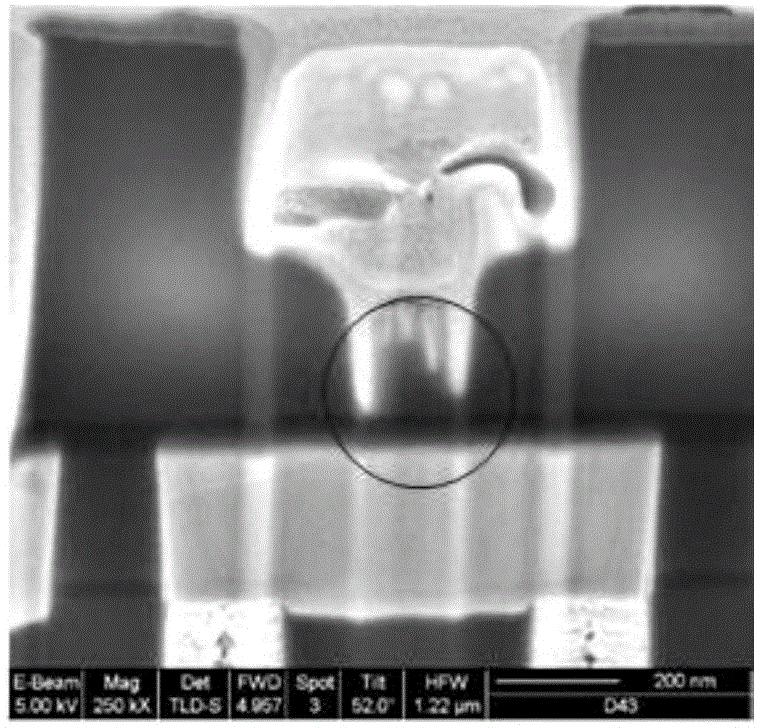

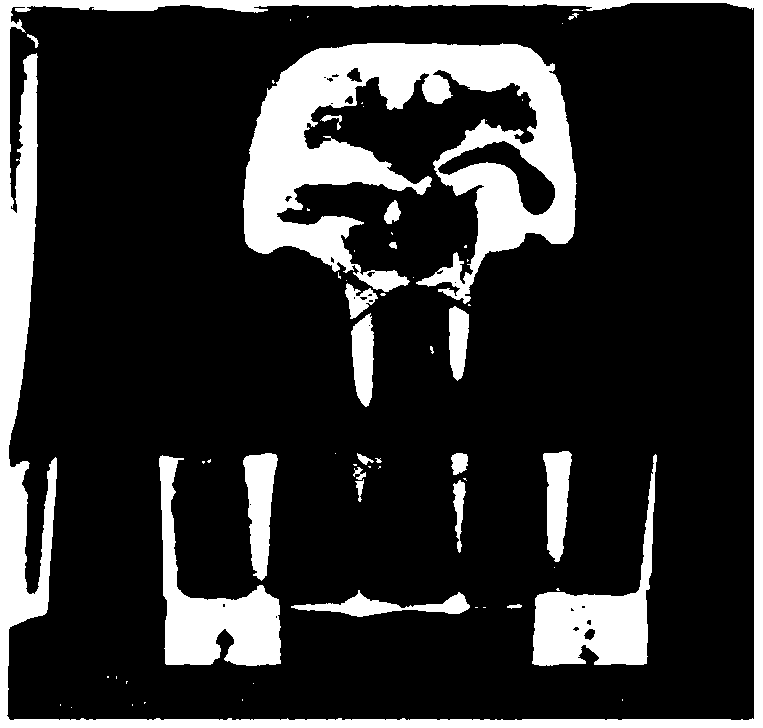

The invention discloses a method for detecting the under-etching and the deficiency defect of a through hole. The method comprises the following steps of implementing a structure that a PMOS (P-channel metal oxide semiconductor) device is arranged in an N well; growing metal silicide on a wafer according to a normal process manufacturing procedure, forming a barrier layer, and depositing a first dielectric layer and a second dielectric layer between metals; sequentially forming a hard mask, a silicon oxide and an antireflection layer on the second dielectric layer, and a hard mask etching photomask on the antireflection layer, wherein a through hole etching photomask is used as the hard mask etching photomask; completely etching the antireflection layer, the silicon oxide and the hard mask by utilizing the hard mask etching photomask, and partially etching the second dielectric layer; removing the hard mask etching photomask, and filling the antireflection layer, the silicon oxide, the hard mask and the second dielectric layer; performing etching by utilizing the through hole etching photomask until the first dielectric layer is partially etched, and removing the through hole etching photomask; removing the antireflection layer and a material, wherein the material is filled in the antireflection layer, and is the same as that of the antireflection layer; and performing etching until the barrier layer is etched through.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

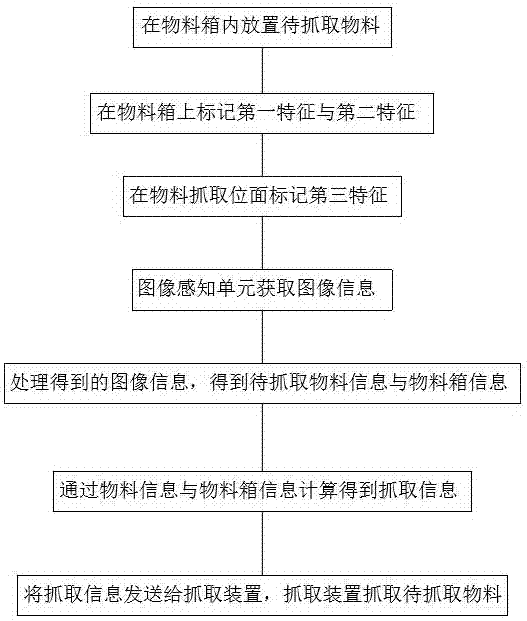

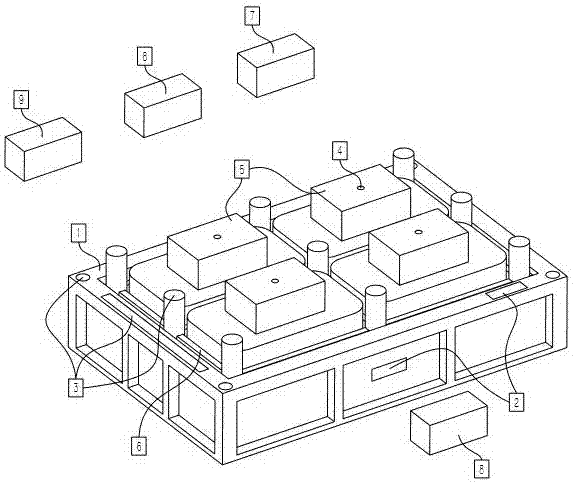

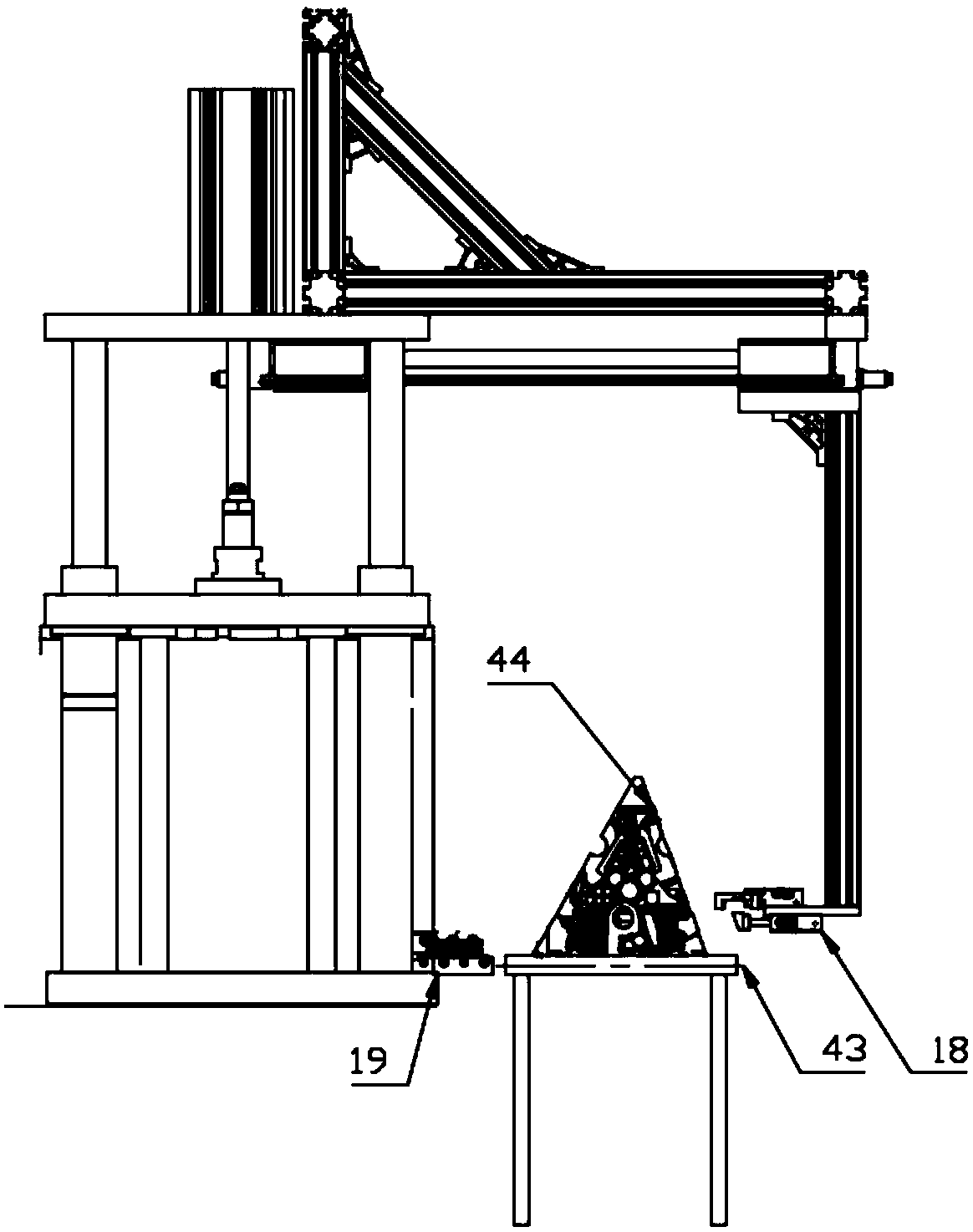

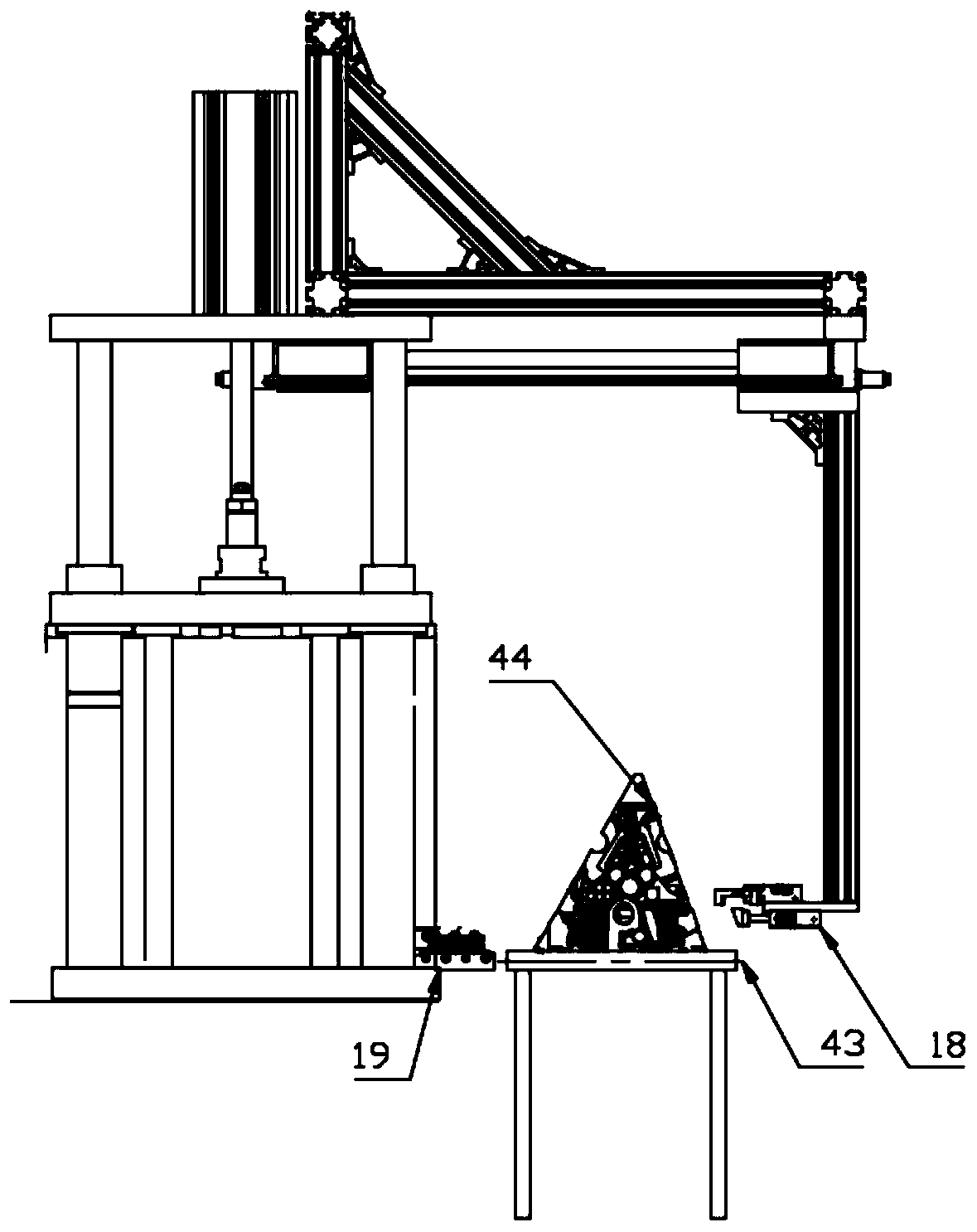

Material grabbing method and system

InactiveCN107160387AImprove adaptabilityImprove robustnessProgramme-controlled manipulatorComputer scienceAdaptive capacity

The invention provides a material grabbing method and system. The method comprises the steps that the position of a material box is acquired, the material box contains at least one kind of materials to be grabbed, grabbing information of the materials to be grabbed is acquired through the position information of the material box and information of the materials to be grabbed, and the materials to be grabbed are grabbed by a grabbing device according to the grabbing information. According to the material grabbing method and system, the position relation of the material box is related to the position information of the materials to be grabbed, in addition, the grabbing device can position and grab objects of different weights, shapes and dimensions at the same time through the grabbing information of the materials to be grabbed, and the adaptive capacity of the material grabbing system is greatly improved.

Owner:陈胜辉

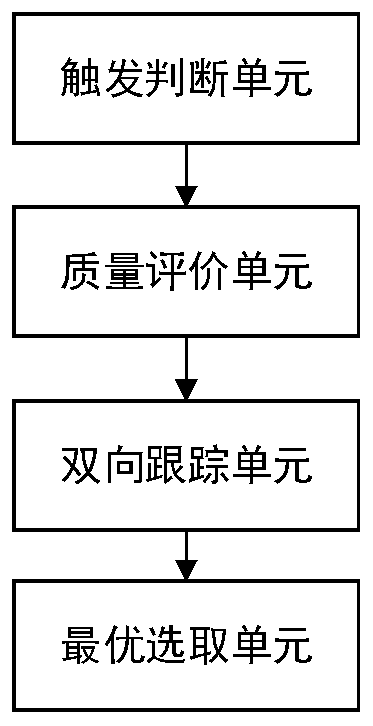

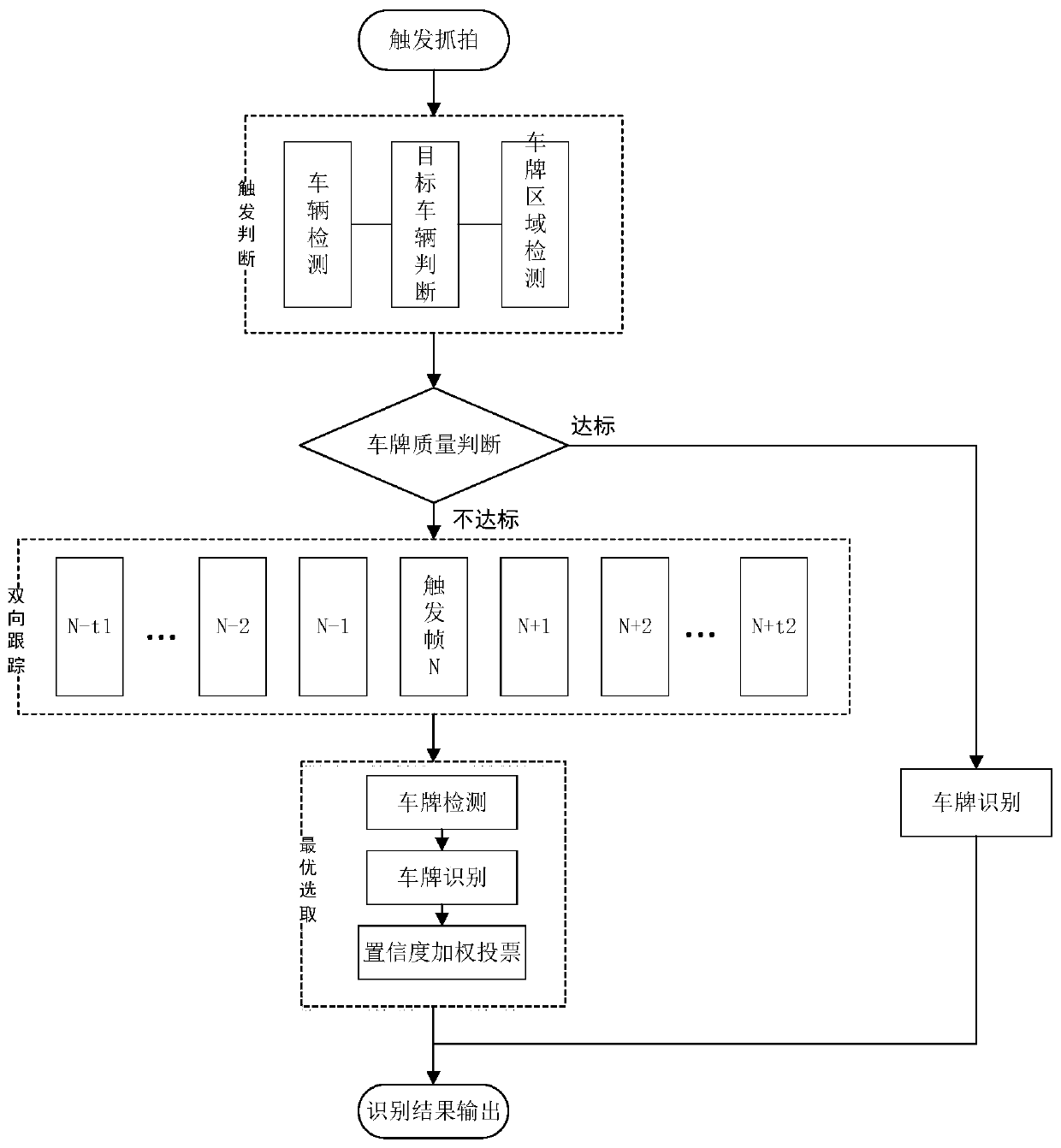

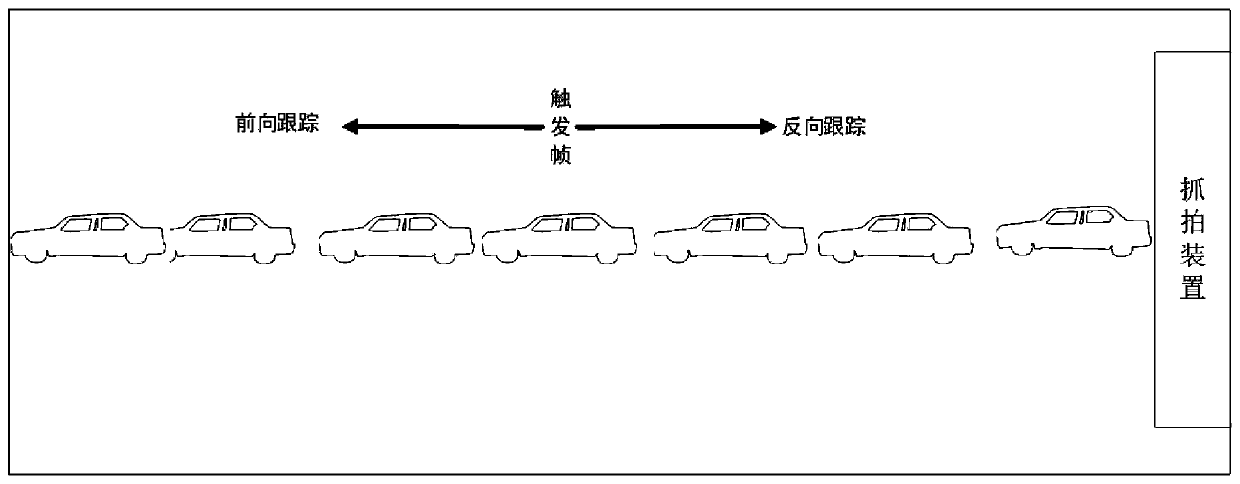

License plate tracking recognition method based on event triggering

ActiveCN111582253ALow crawl rateLow recognition accuracyRoad vehicles traffic controlCharacter and pattern recognitionEngineeringVehicle detection

The invention discloses a license plate tracking recognition method based on event triggering. The method comprises the following steps of performing vehicle detection and license plate extraction ona trigger frame at the trigger moment to obtain vehicle coordinates or a license plate area, and performing target vehicle judgment; and starting video stream tracking under the condition that whetherthe license plate quality evaluation of the target vehicle exceeds a specified threshold, performing license plate region judgment on a target vehicle region in the tracked video stream, and finallyobtaining a finally identified license plate through identification voting. According to the invention, bidirectional simultaneous frame-by-frame decoding and vehicle license plate tracking identification are carried out by taking the trigger frame as a reference in the video stream, so that the length of the intercepted video stream is effectively reduced and the tracking identification efficiency is improved; according to the tracked license plate, the confidence degree and the voting mechanism are integrated, and the situation that the single-frame license plate is poor in quality in some scenes is avoided.

Owner:SHANGHAI KEYGO TECH CO LTD

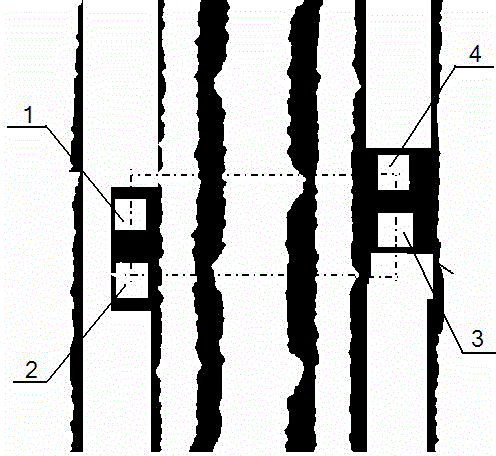

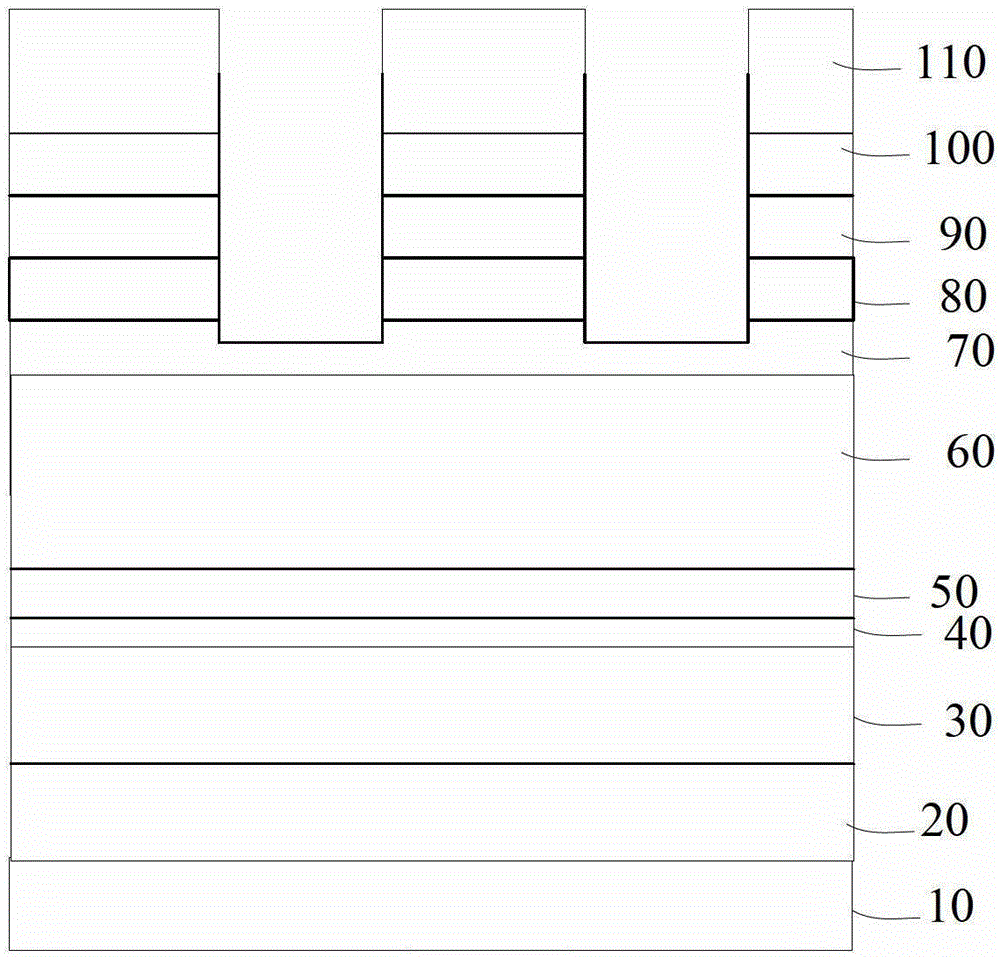

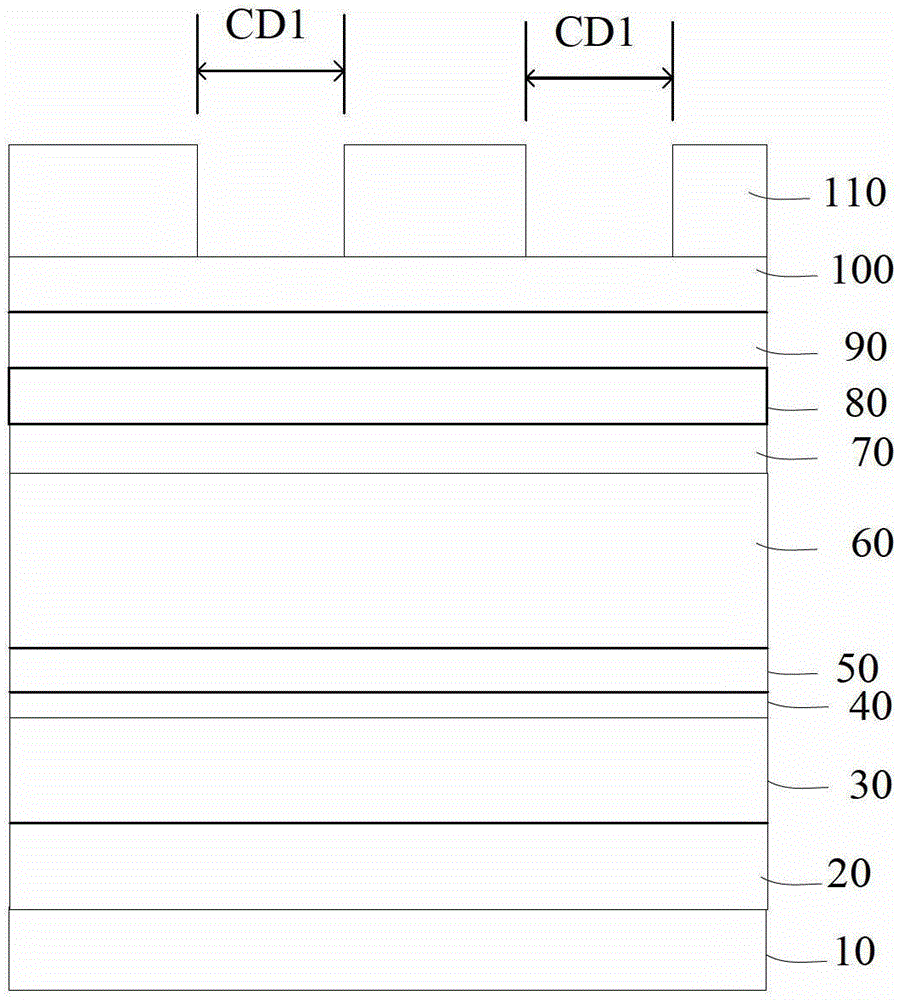

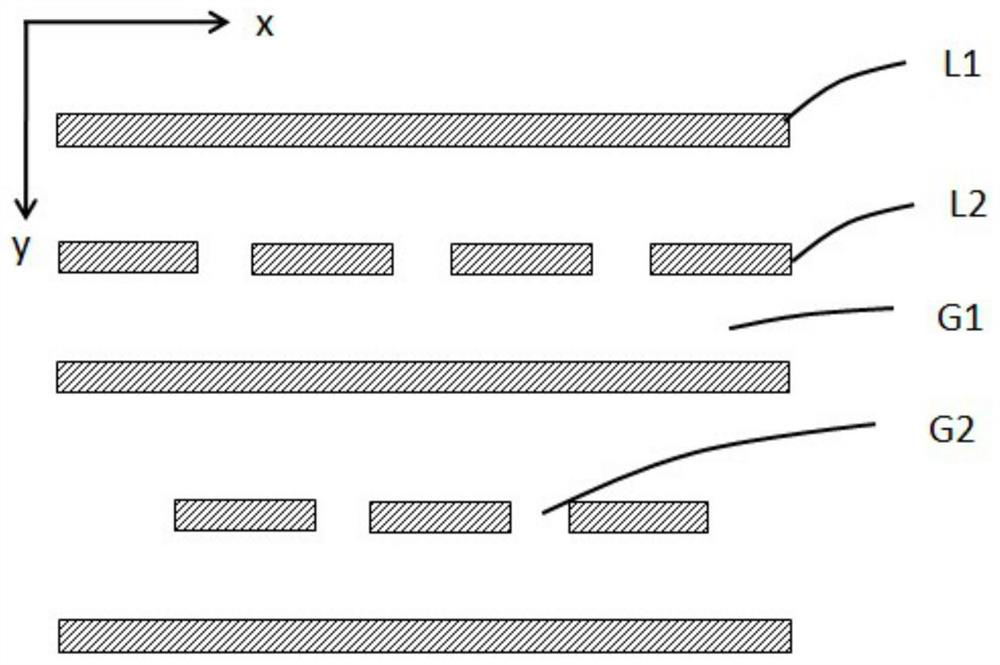

Method for detecting etching insufficiency of through hole

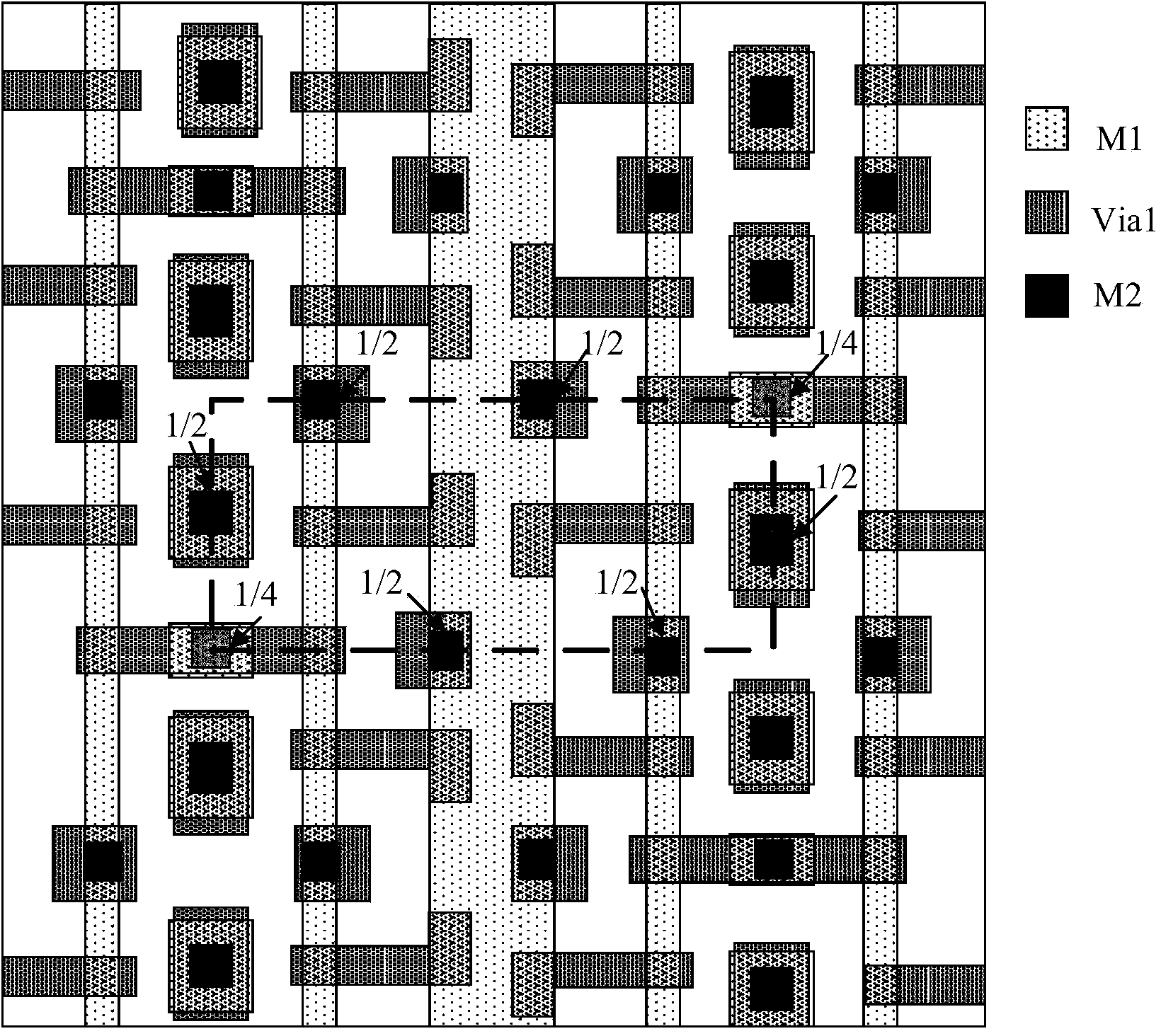

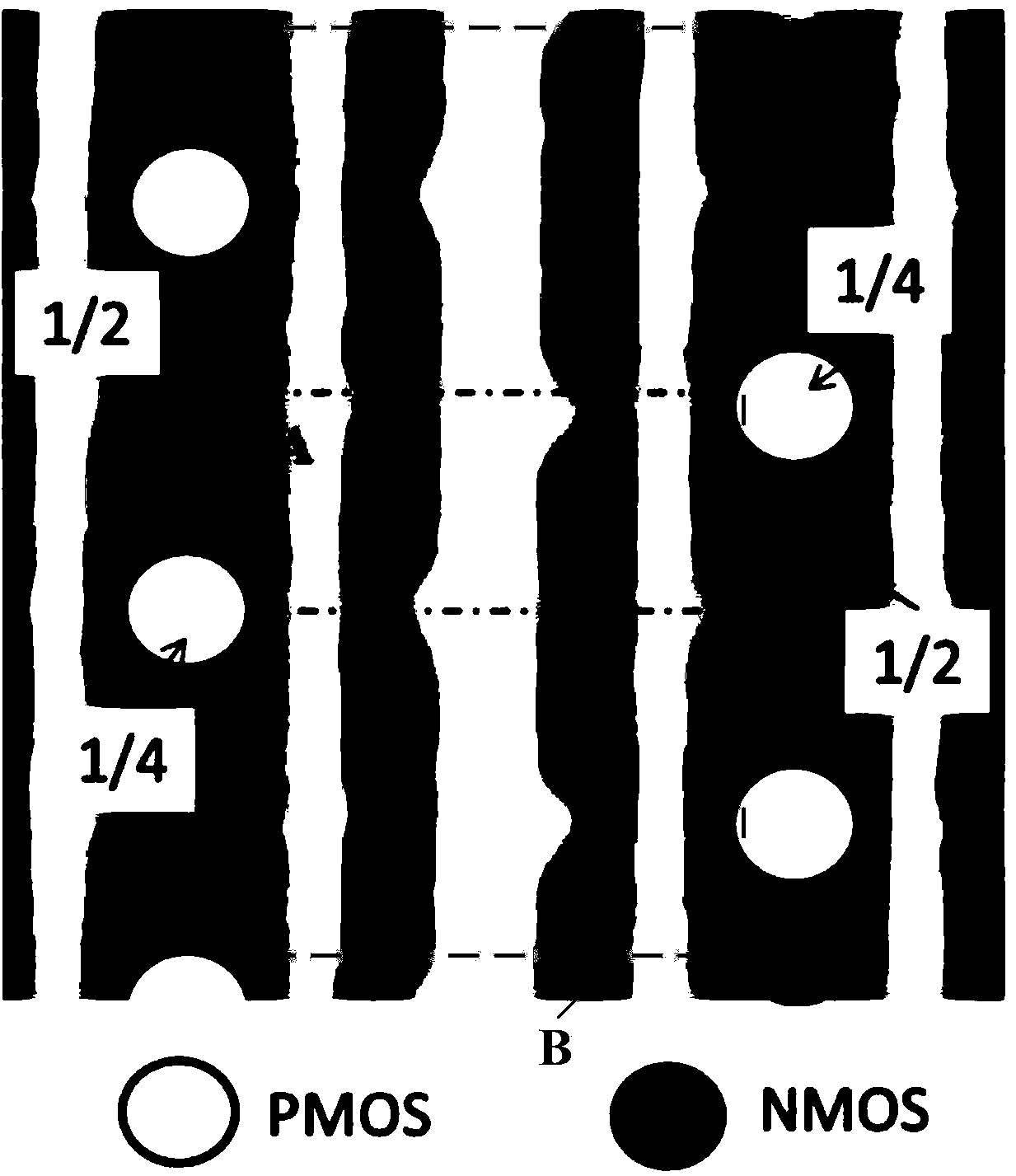

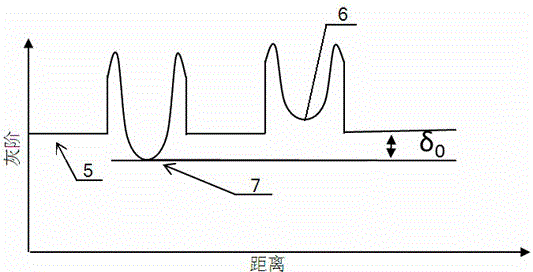

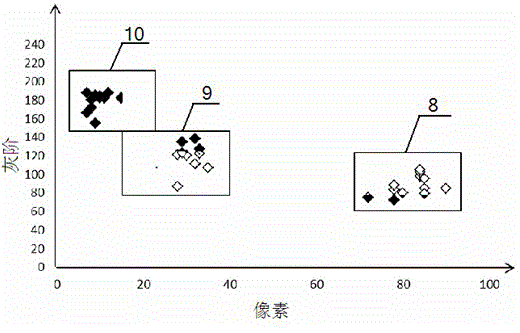

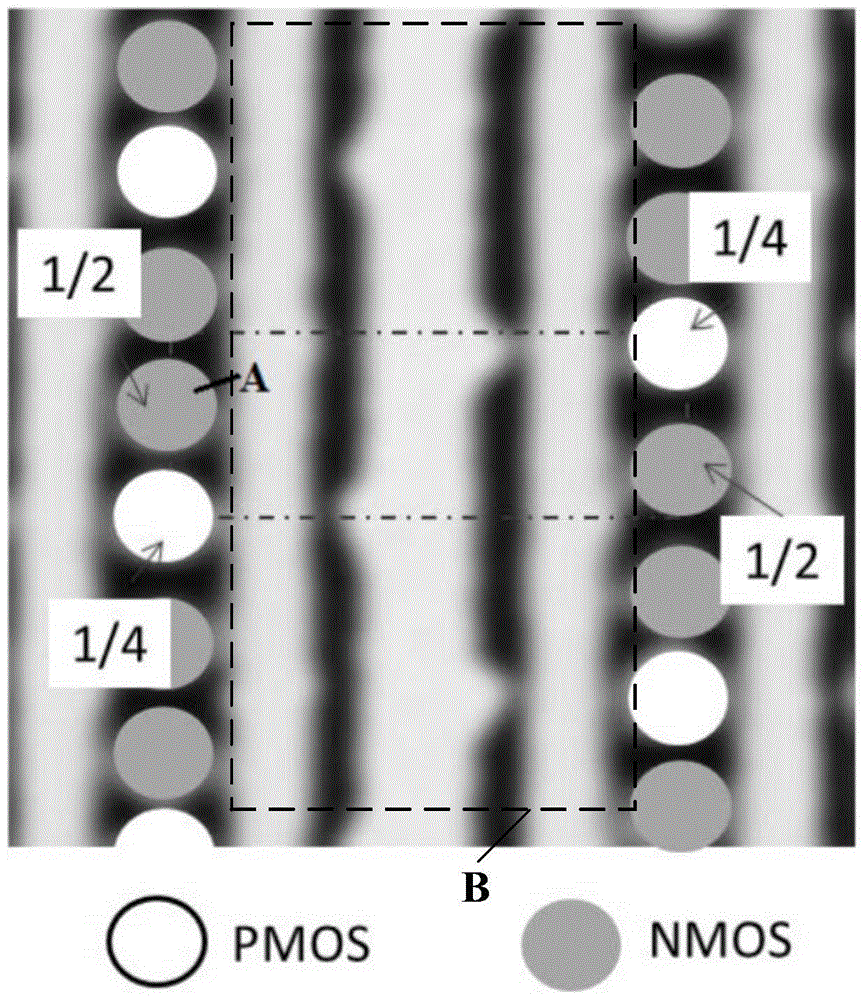

ActiveCN104091769AImprove crawl rateHigh monitoring sensitivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTransmission gateImaging Feature

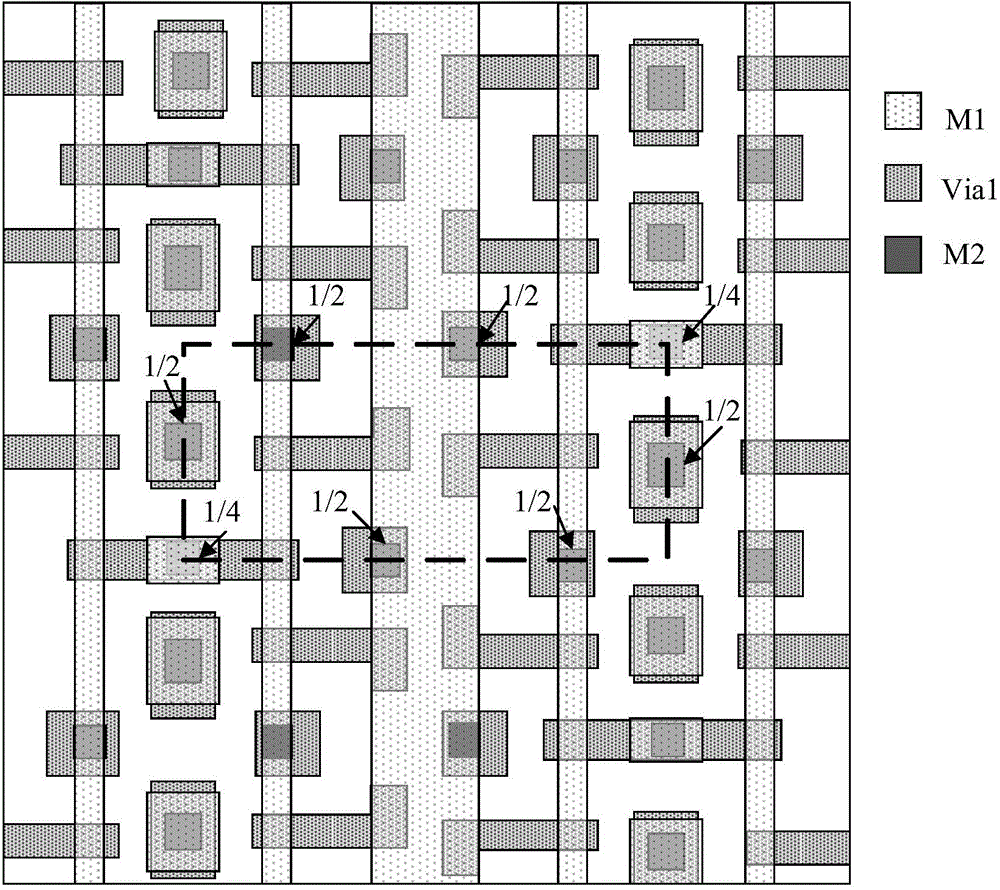

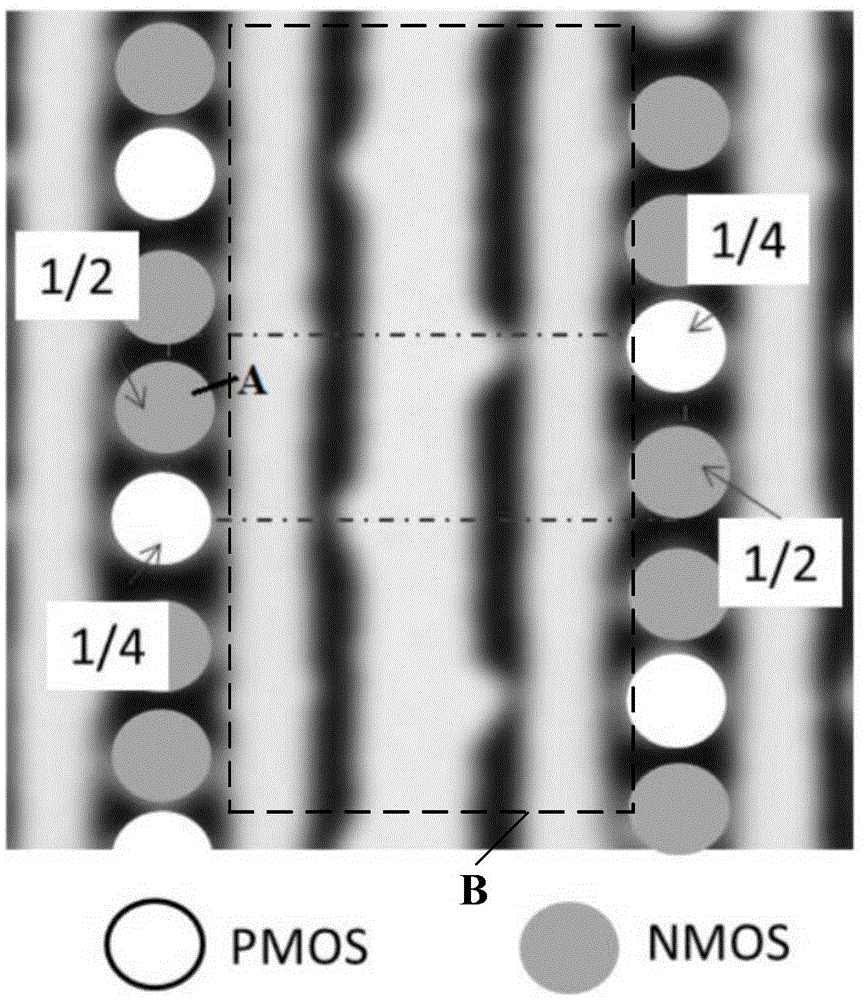

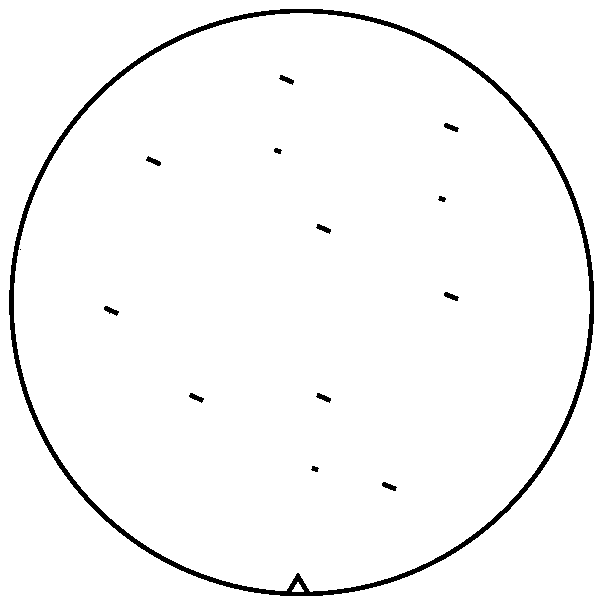

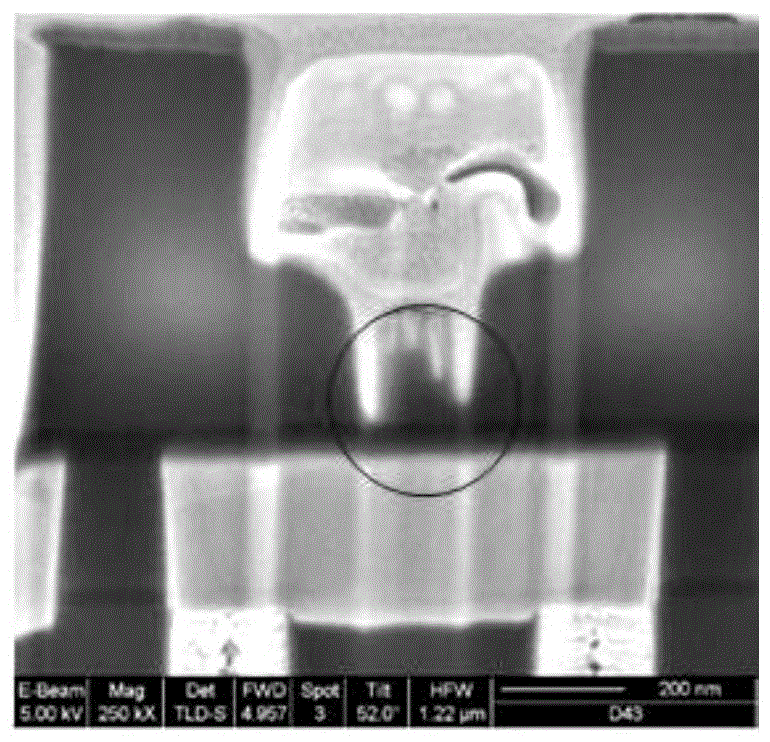

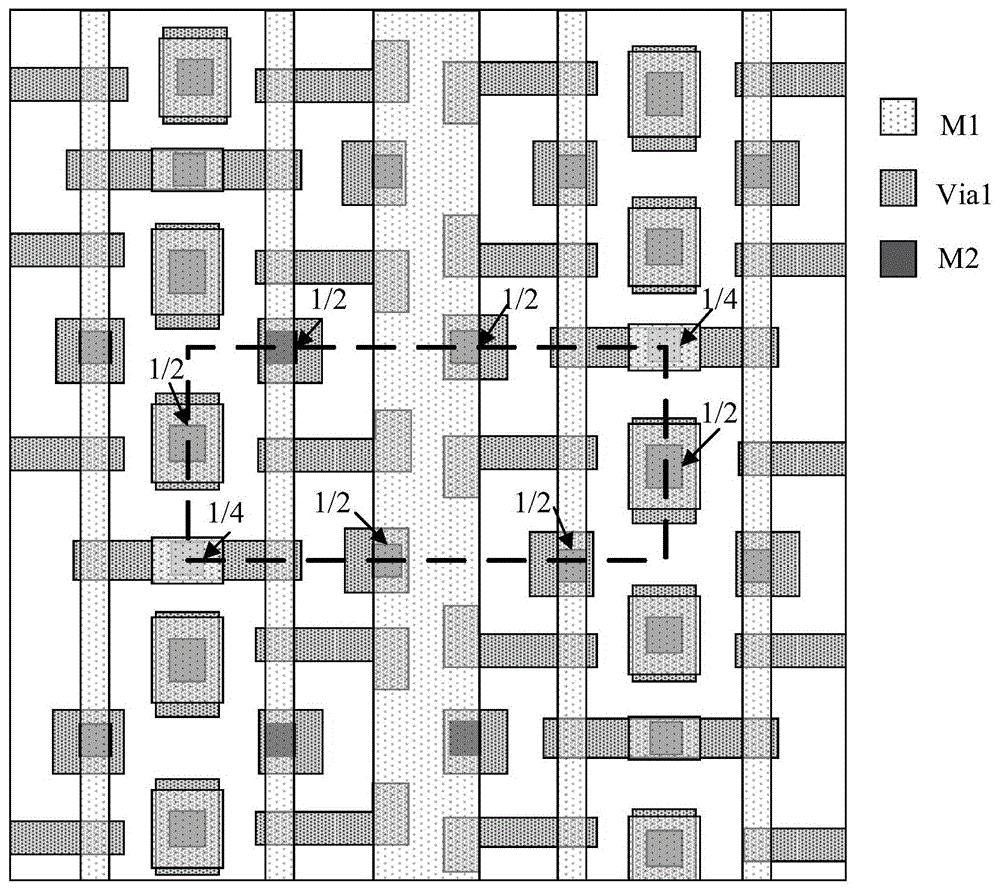

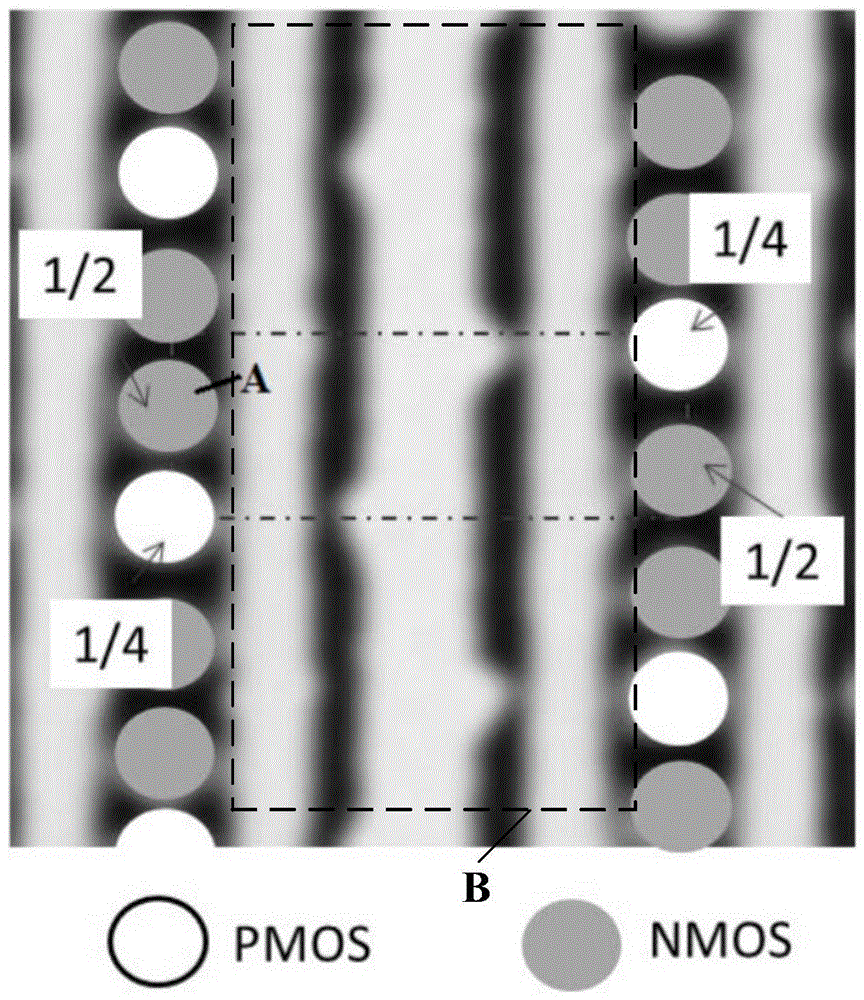

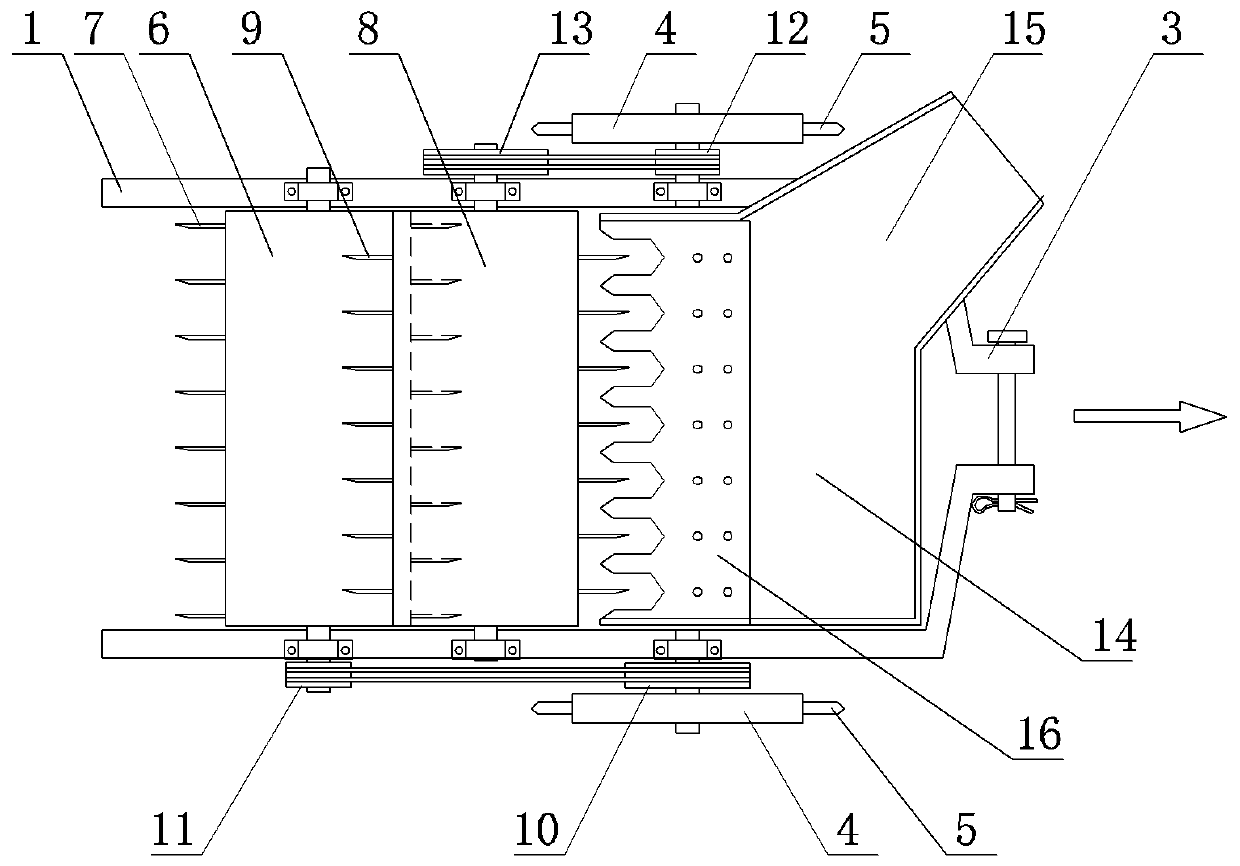

The invention discloses a method for detecting etching insufficiency of through holes. The method comprises the steps that a plurality of test modules are built on a semiconductor substrate, each test module simulates an SRAM device structure and comprises two simulation transmission gate transistors, two simulation pull-up transistors and two simulation pull-down transistors, the simulation transmission gate transistors, the simulation pull-up transistors and the simulation pull-down transistors are PMOS devices in an N well, and no grid electrode is formed on active areas of the simulation transmission gate transistors; a plurality of contacting holes are formed in each test module and filled with metal, and the contacting holes are at least connected with positions, corresponding to grid electrodes, in the active areas of the simulation transmission gate transistors; a metal interconnection line and a conduction through hole are formed on each contacting hole; the test modules are scanned through an electron beam defect scanner under a positive potential condition, and the etching insufficiency defects of the through holes of the test modules are detected according to the image feature pictures obtained through scanning. The method for detecting etching insufficiency of the through holes can effectively improve the capturing efficiency of the etching insufficiency defects.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

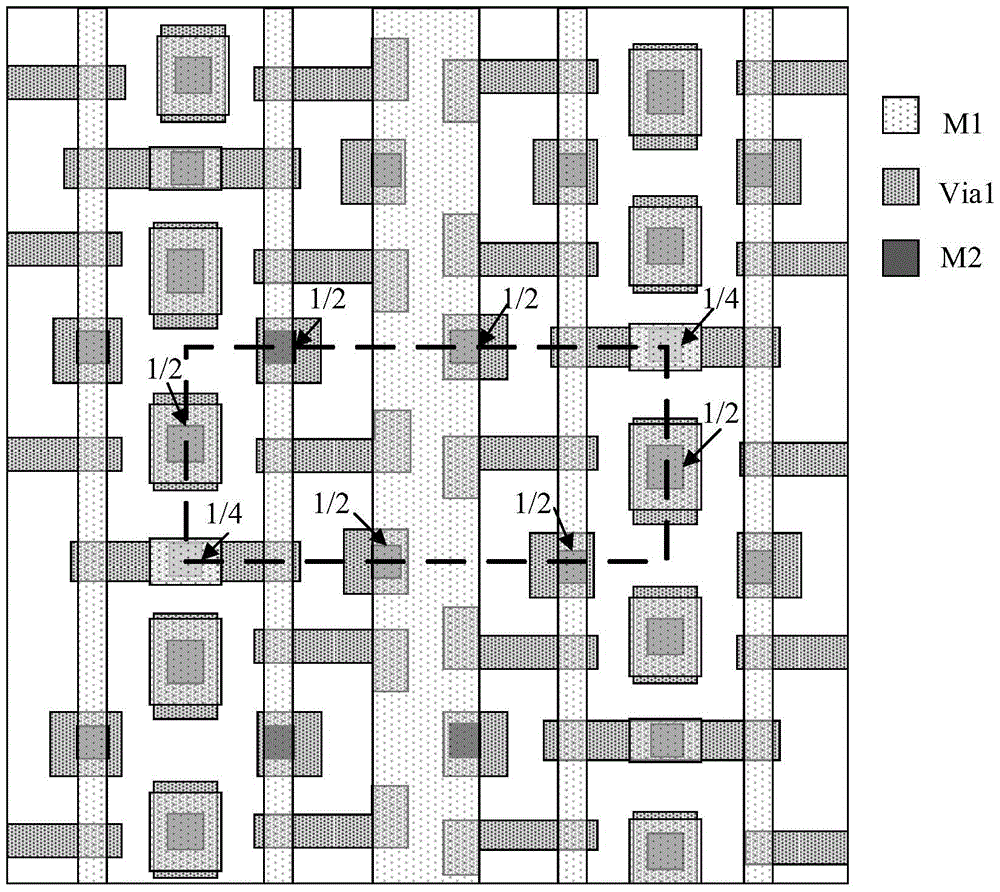

Detection method for under-etching of through holes

ActiveCN104078379AIncrease the number of viasImprove crawl rateSemiconductor/solid-state device testing/measurementEtchingTransmission gate

The invention discloses a detection method for under-etching of through holes. The method comprises the following steps: a plurality of test modules are built on the substrate of a semiconductor, each test module simulates an SRAM device structure and comprises two simulation transmission gate transistors, two simulation pull-up transistors and two simulation pull-down transistors; the simulation transmission gate transistors, the simulation pull-up transistors and the simulation pull-down transistors are NMOS devices in a P trap, and a grid electrode is not formed in the active area of each simulation transmission gate transistor; a plurality of contact holes filled with metal are formed in each test module; the contact holes are connected with the position, corresponding to the grid electrode, of the active area of each simulation transmission gate transistor at least; metal interconnecting wires and conductive through holes are formed in the contact holes; test modules are scanned under the positive potential condition by an electron beam defect scanner, and the defect of under-etching of through holes of the test modules is detected according to image characteristic patterns obtained through scanning. The method provided by the invention can increase the capturing rate of the defect of under-etching.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

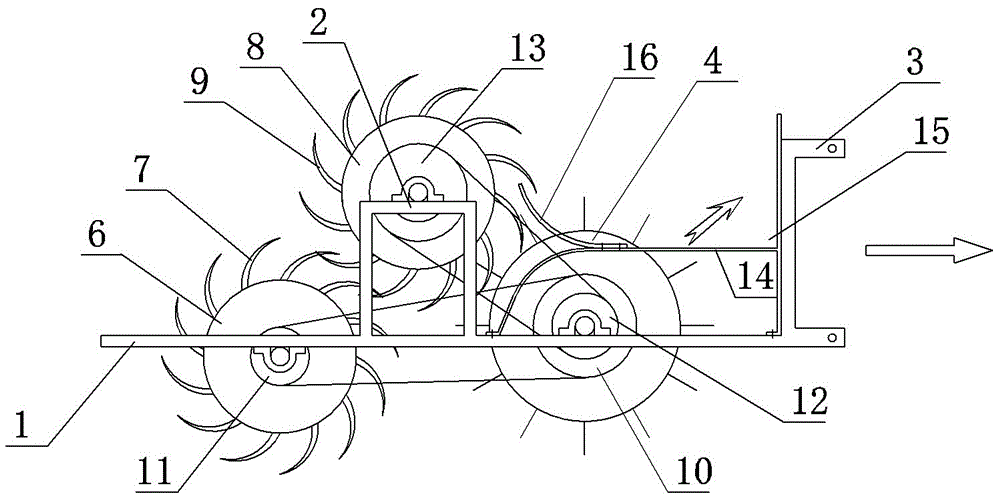

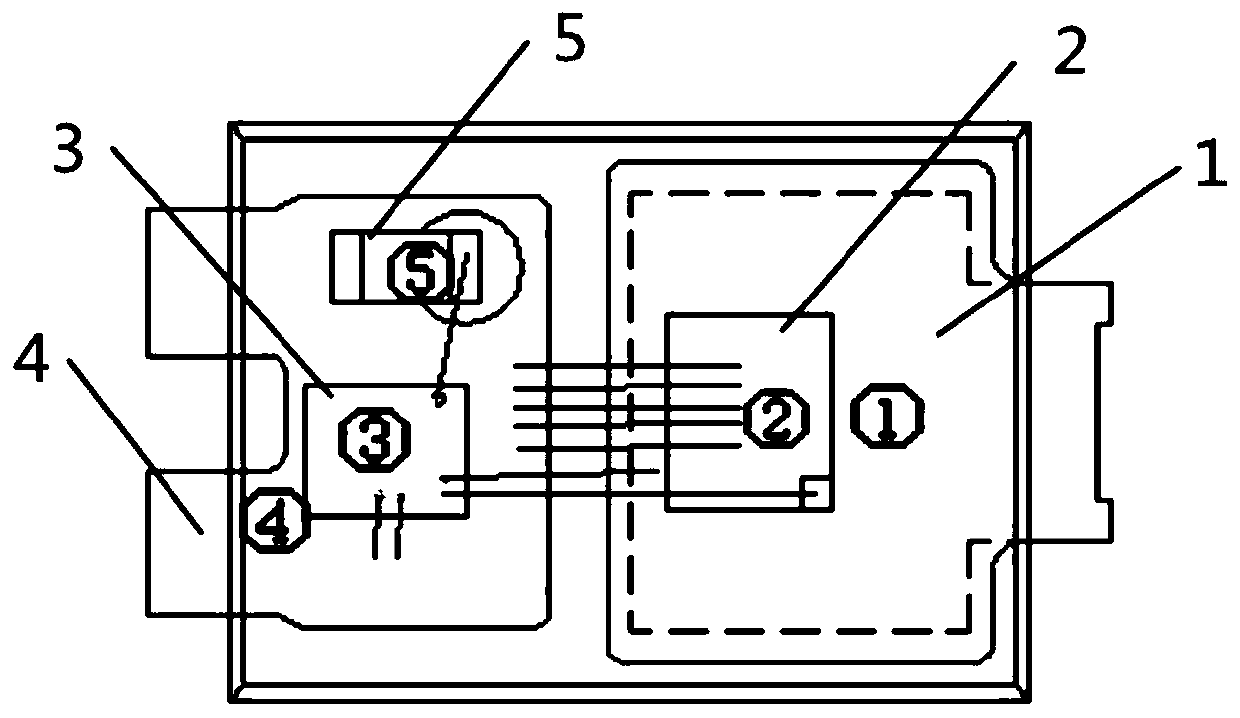

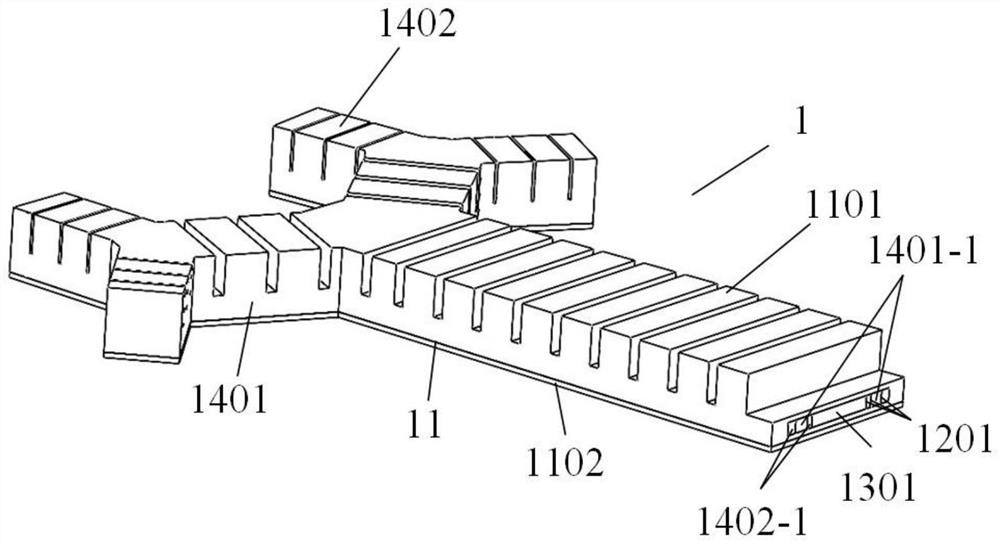

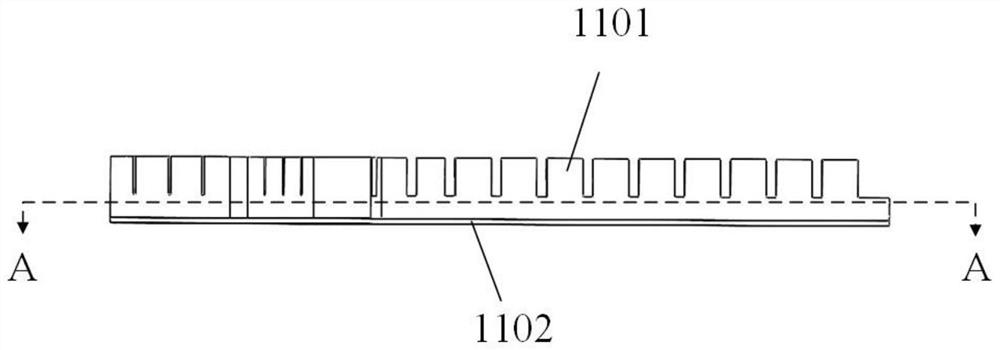

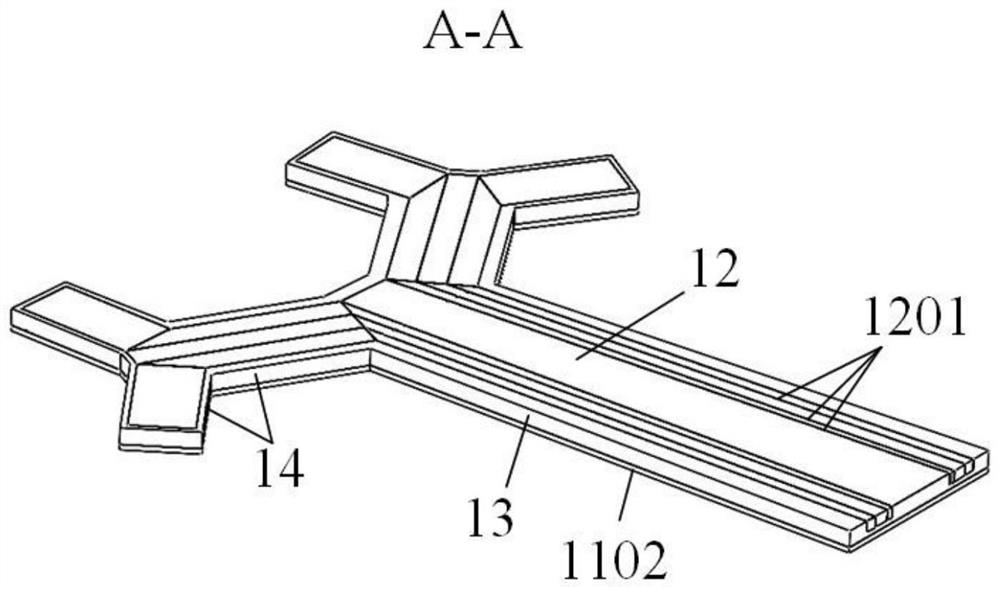

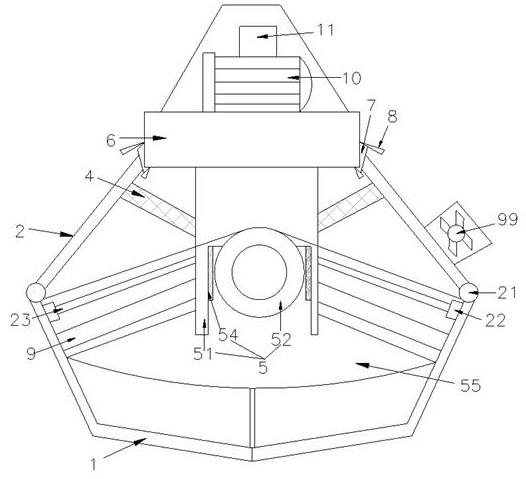

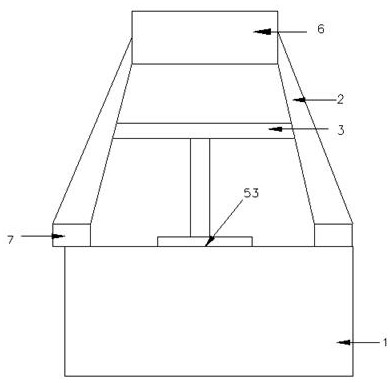

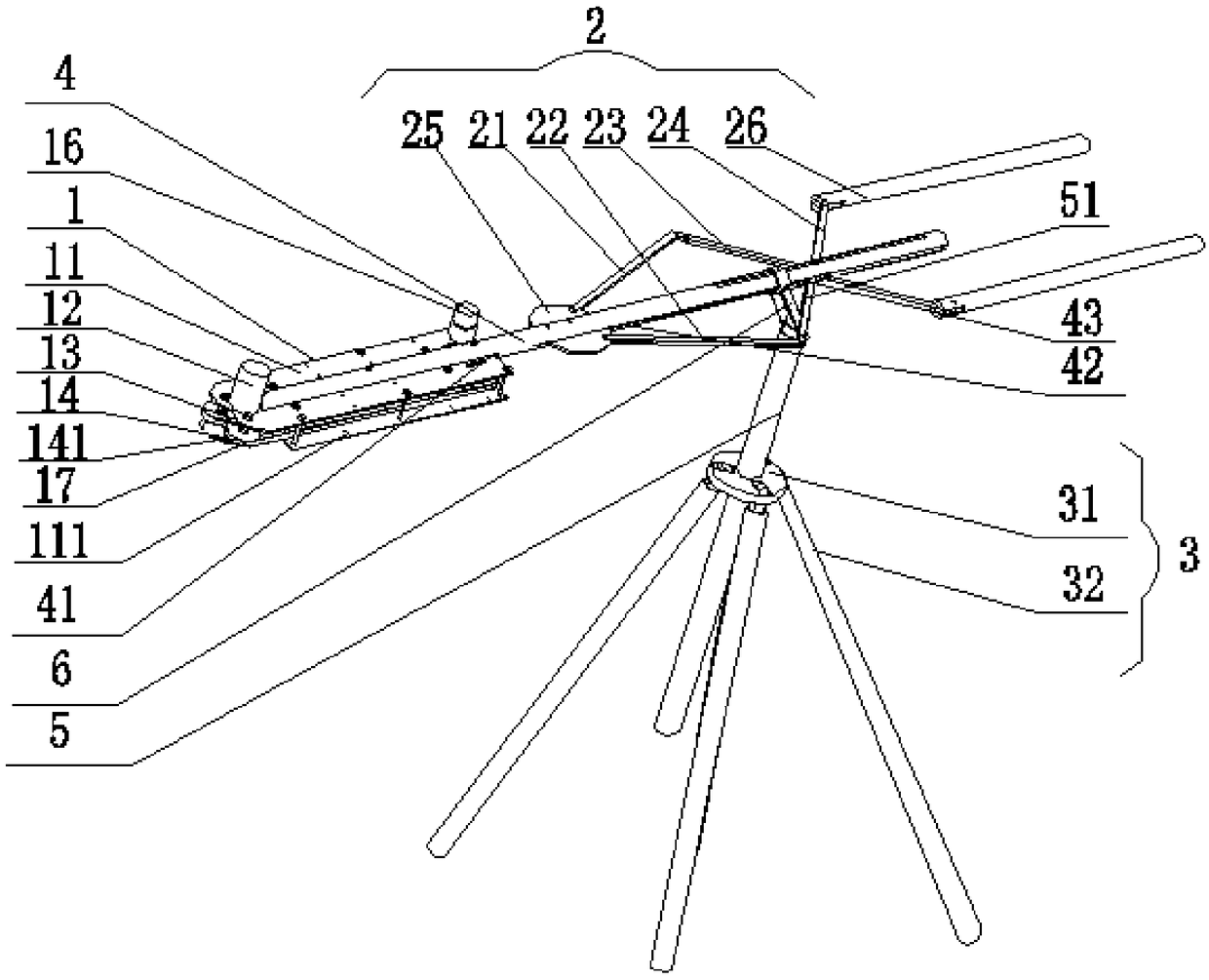

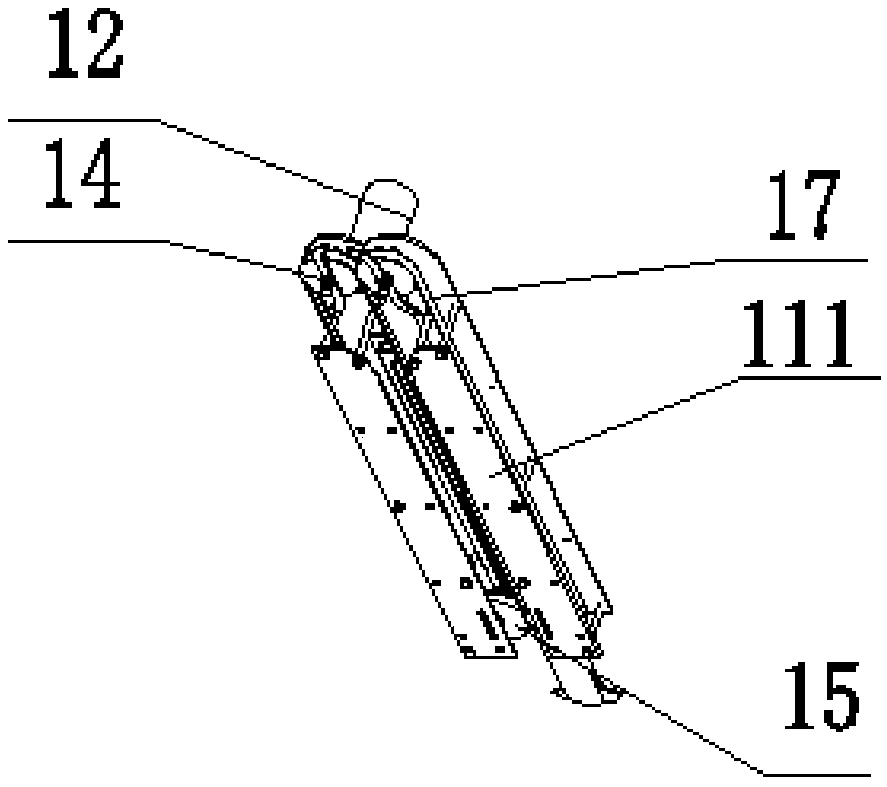

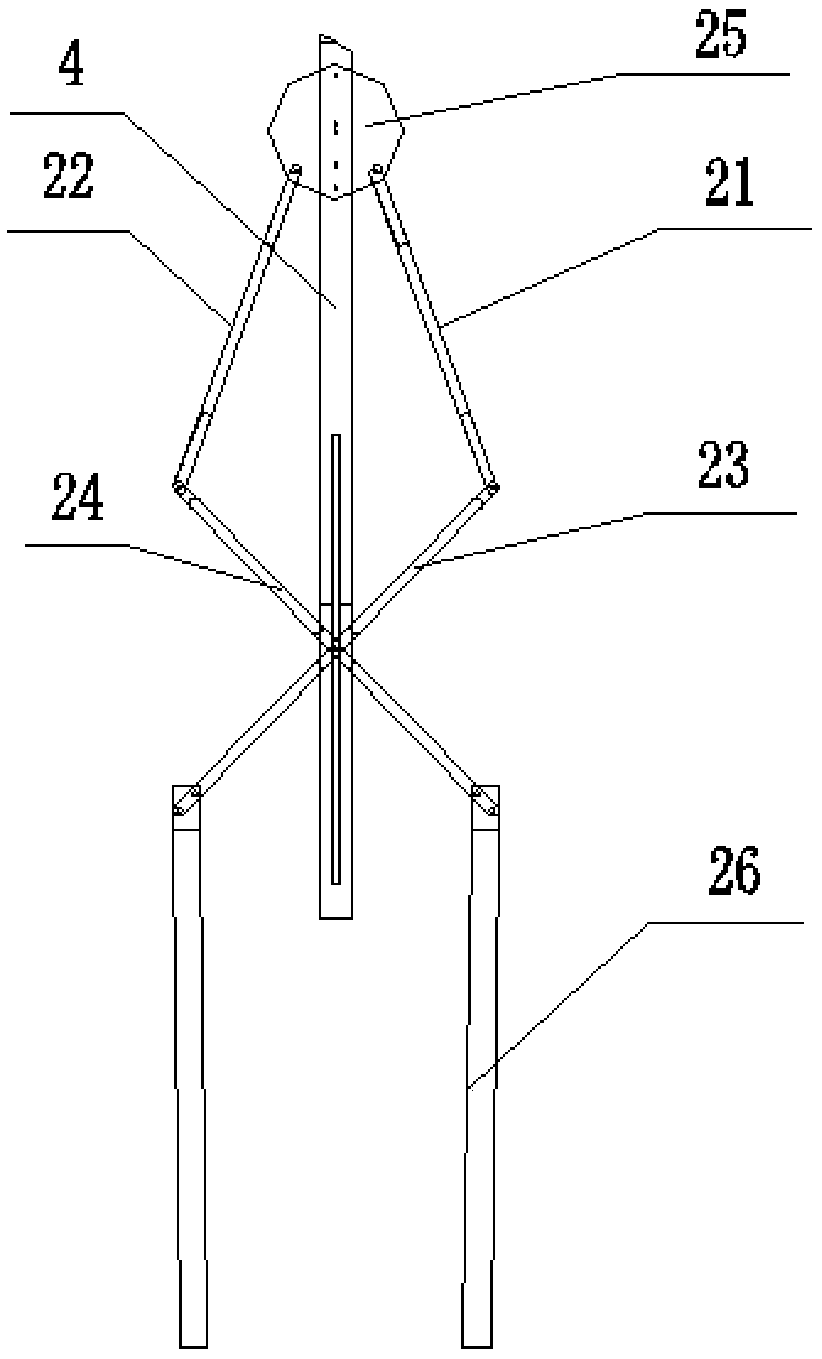

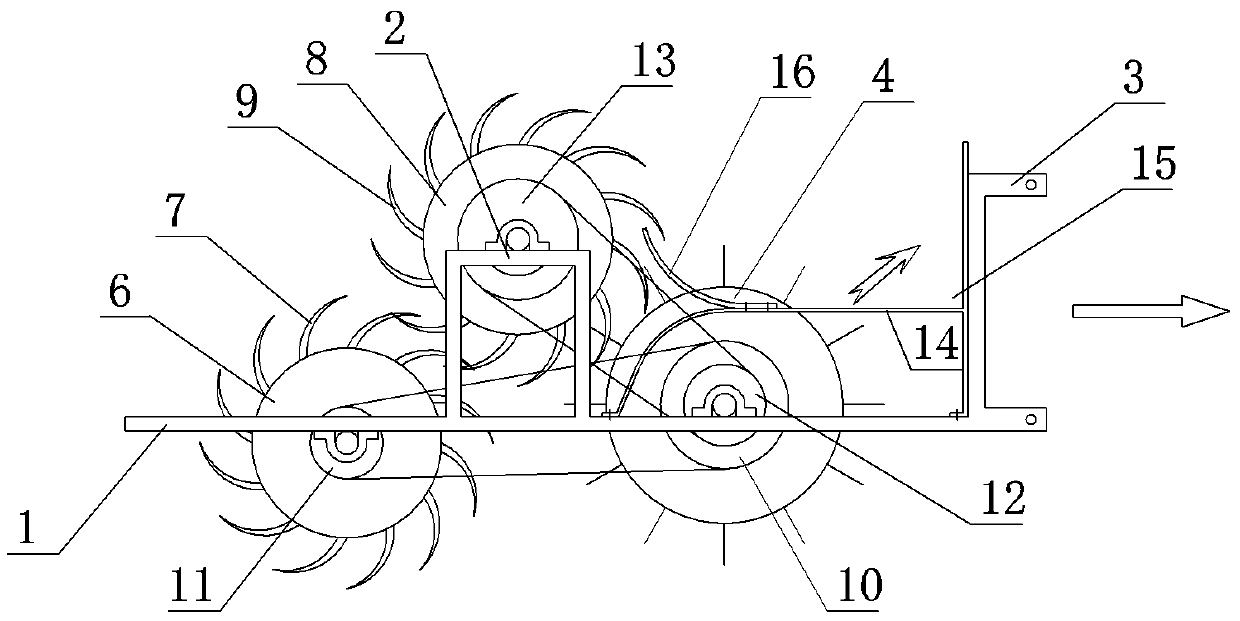

Traction drive type mulching film recycling machine

ActiveCN106717173AIncrease speedIncrease success rateGatherer machinesVehicle frameAgricultural engineering

The invention discloses a traction drive type mulching film recycling machine. The traction drive type mulching film recycling machine comprises a machine frame and a film grabbing mechanism. The machine frame is provided with a car floor beam, a car top beam and a traction end connector. A film grabbing roller is arranged on the car floor beam through a bearing, a film connecting roller is installed on the car top beam through a bearing, film grabbing teeth are arranged on the outer surface of the film grabbing roller, film connecting teeth are arranged on the film connecting roller, and the film connecting teeth and the film connecting teeth are arranged in a straggled mode. A rotary shaft of a land wheel is provided with a first driving wheel and a second driving wheel which drive the film grabbing roller and the film connecting roller to rotate respectively. The number of the film grabbing times is increased, and the mulching film recycling machine is used for improving the film grabbing rate. A speed difference exists between the film grabbing roller and the film connecting roller, so that multiple coincidence chances exist between the film grabbing teeth and the film connecting teeth, and the film connecting success rate is increased. Upward oblique or bent film connecting transition plate avoiding grooves can go deep between the film connecting teeth, and film residues between the film connecting teeth are shoveled out and then slide down to a film discharging channel.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

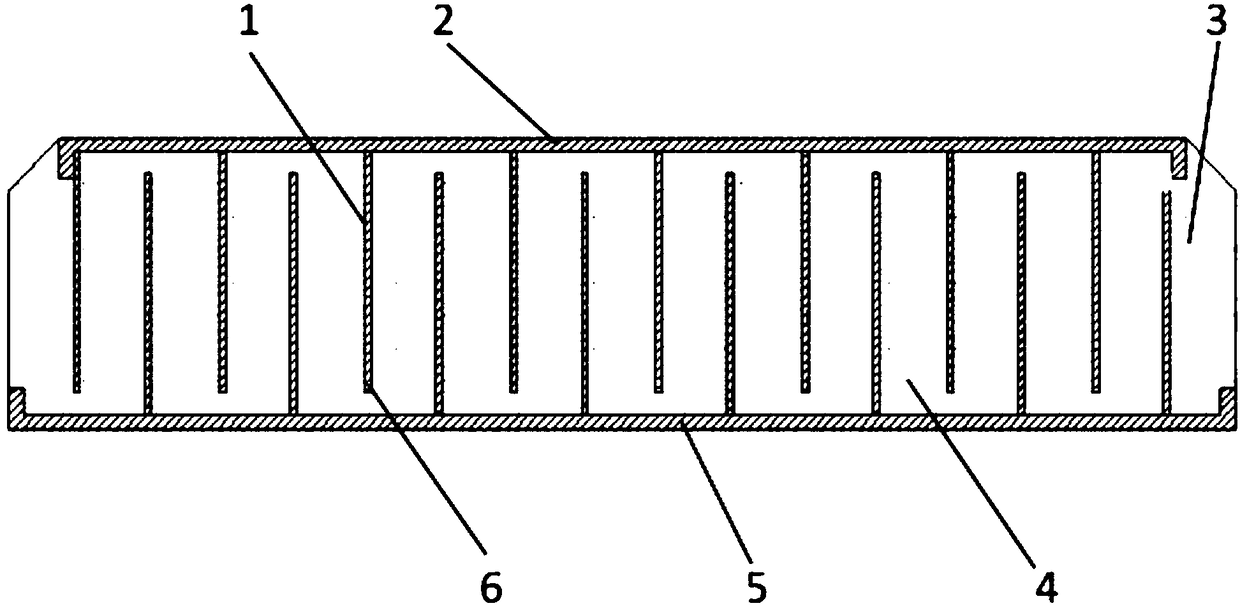

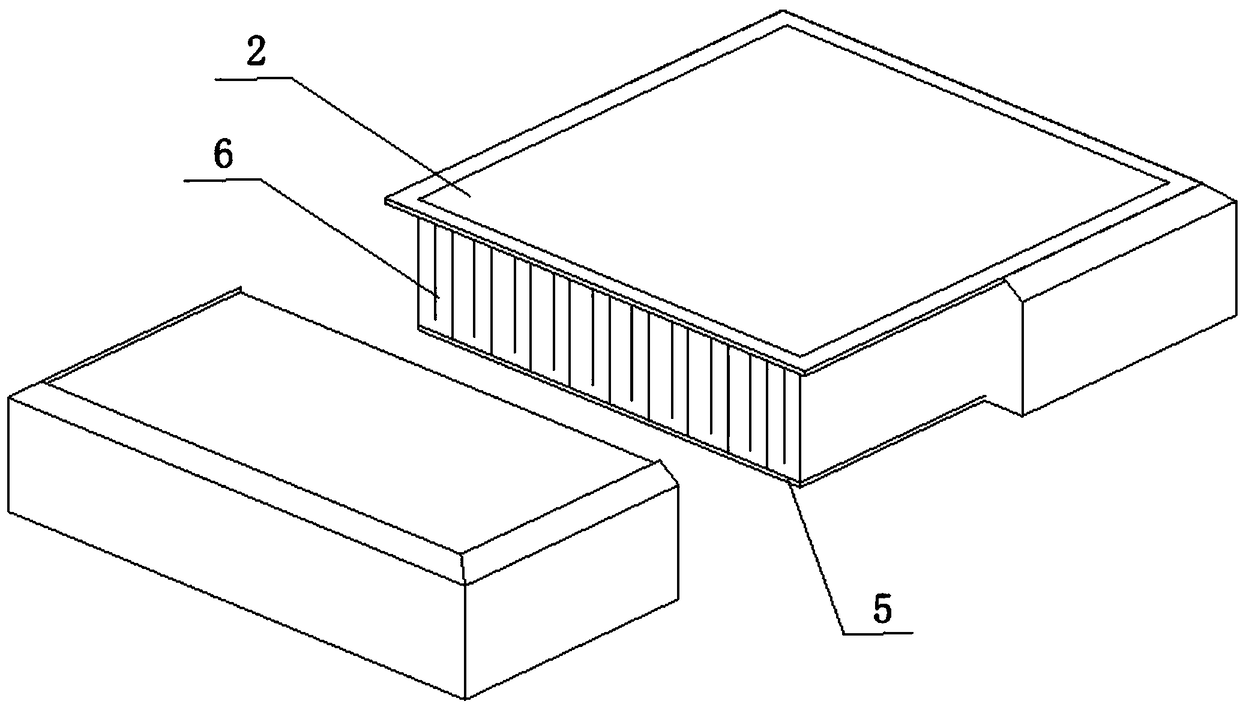

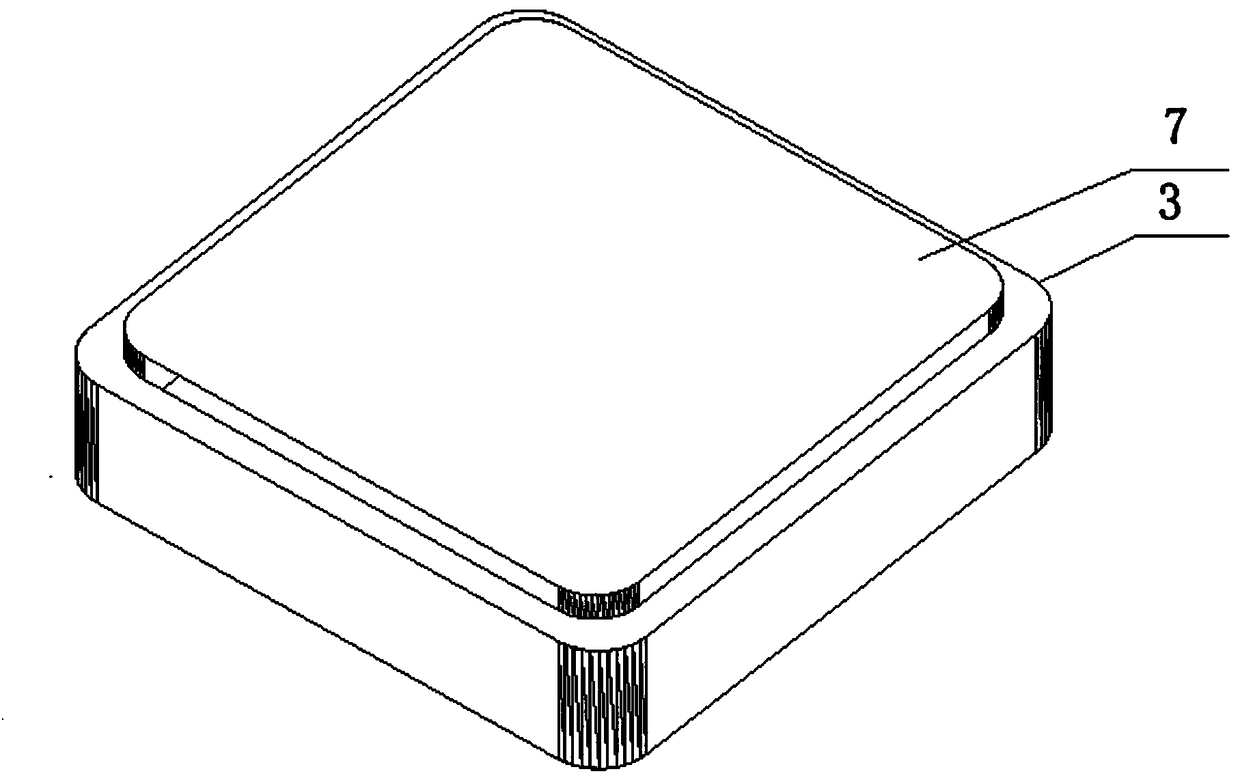

Vertical chip capacitor and manufacturing process thereof

ActiveCN108074739ASimple internal structureSolve application problemsFixed capacitor electrodesFixed capacitor dielectricCapacitanceCapacitor

The invention discloses a vertical chip capacitor and a manufacturing process thereof, and belongs to the technical field of microelectronics. The capacitor comprises a capacitor substrate, the capacitor substrate comprises an upper end face and a lower end face, inner electrodes are arranged on the inner side of the upper end face and the lower end face, the inner electrodes comprise upper electrodes and lower electrodes, the upper electrodes and the lower electrodes are vertically arranged in a scattered mode, one ends of the upper electrodes are connected with the upper end face, the otherends of the upper electrodes are not in contact with the lower end face, the lower electrodes are connected with the lower end face, and the other ends of the lower electrodes are not in contact withthe upper end face; metal layers are arranged on the outer sides of the upper end face and the lower end face to form external terminal electrodes, and the terminal electrodes are parallel to an installation surface and are connected with the inner electrodes. According to the capacitor, an inner structure of the capacitor is improved to solve the capacitor application problem in a thinned and small-sized sealing member, and the capacitor is vertically arranged, so that sacrifice does not needed on a framework to ensure completeness of the framework, and meanwhile the purposes of changing capacitor shape and electrode direction are achieved by changing a printing technology, a cutting method and a coating technology of the electrodes.

Owner:山东芯诺电子科技股份有限公司

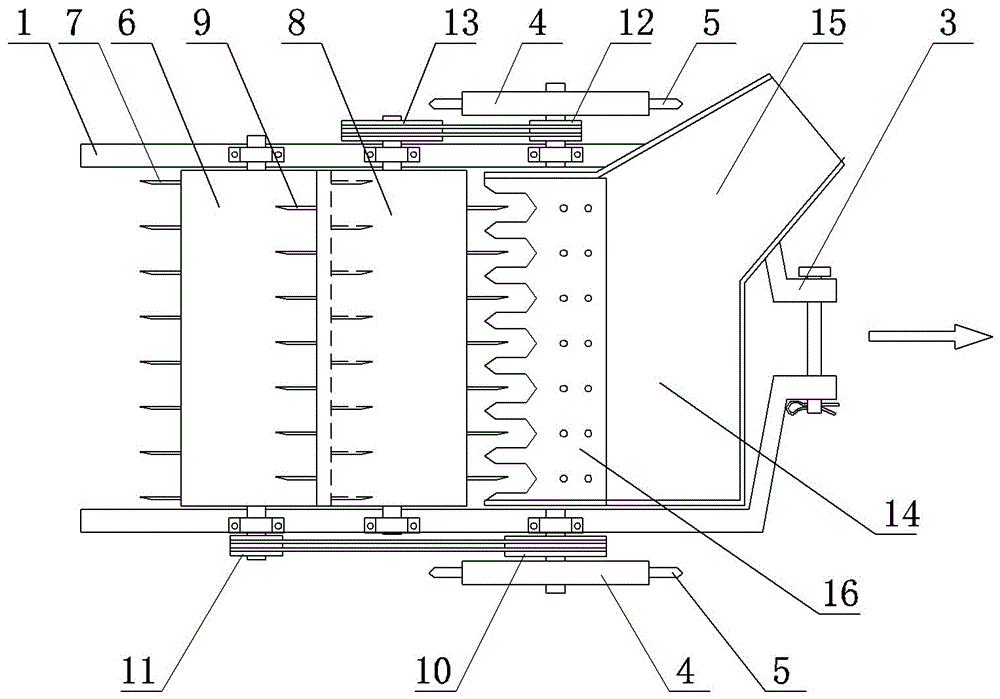

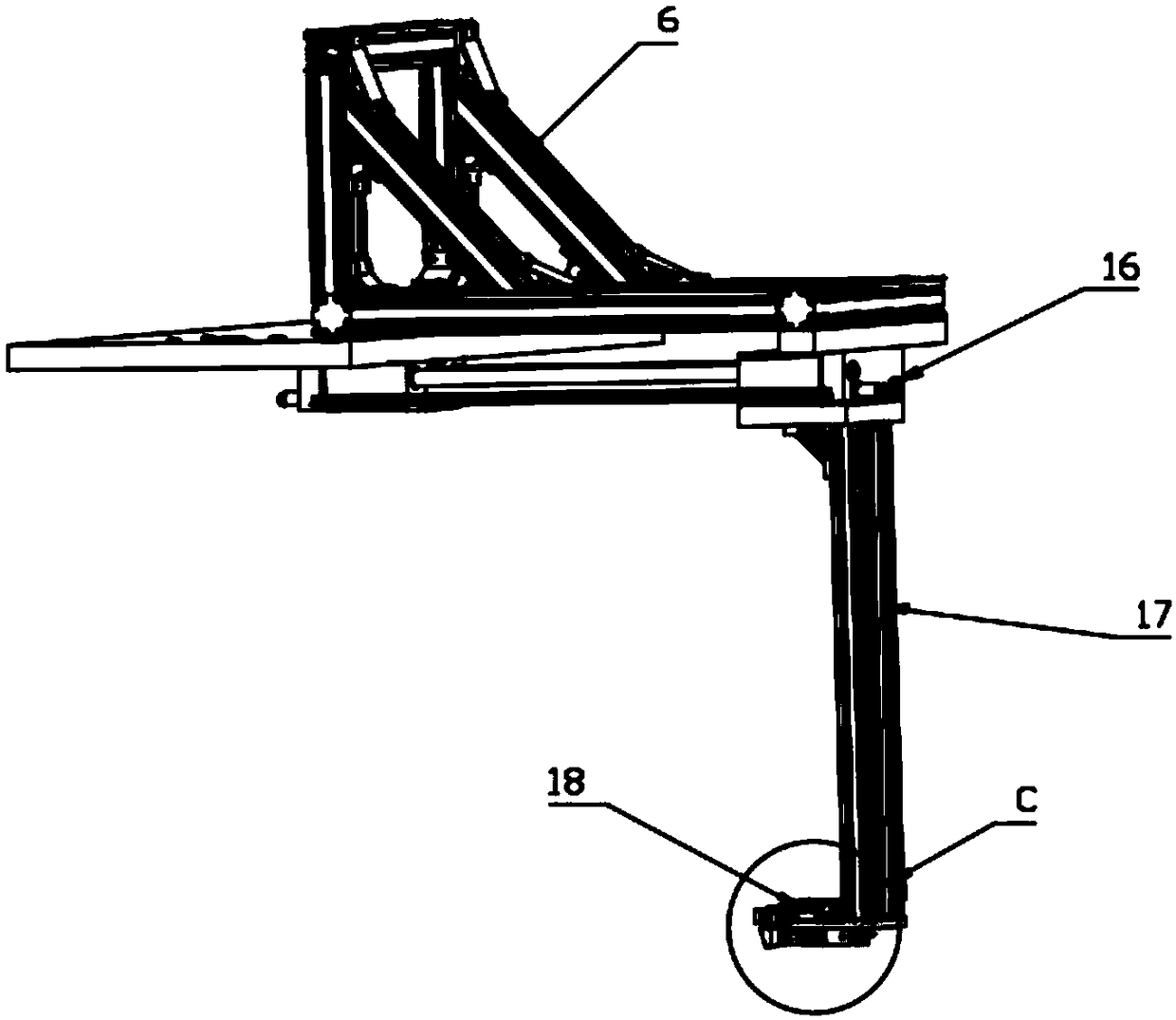

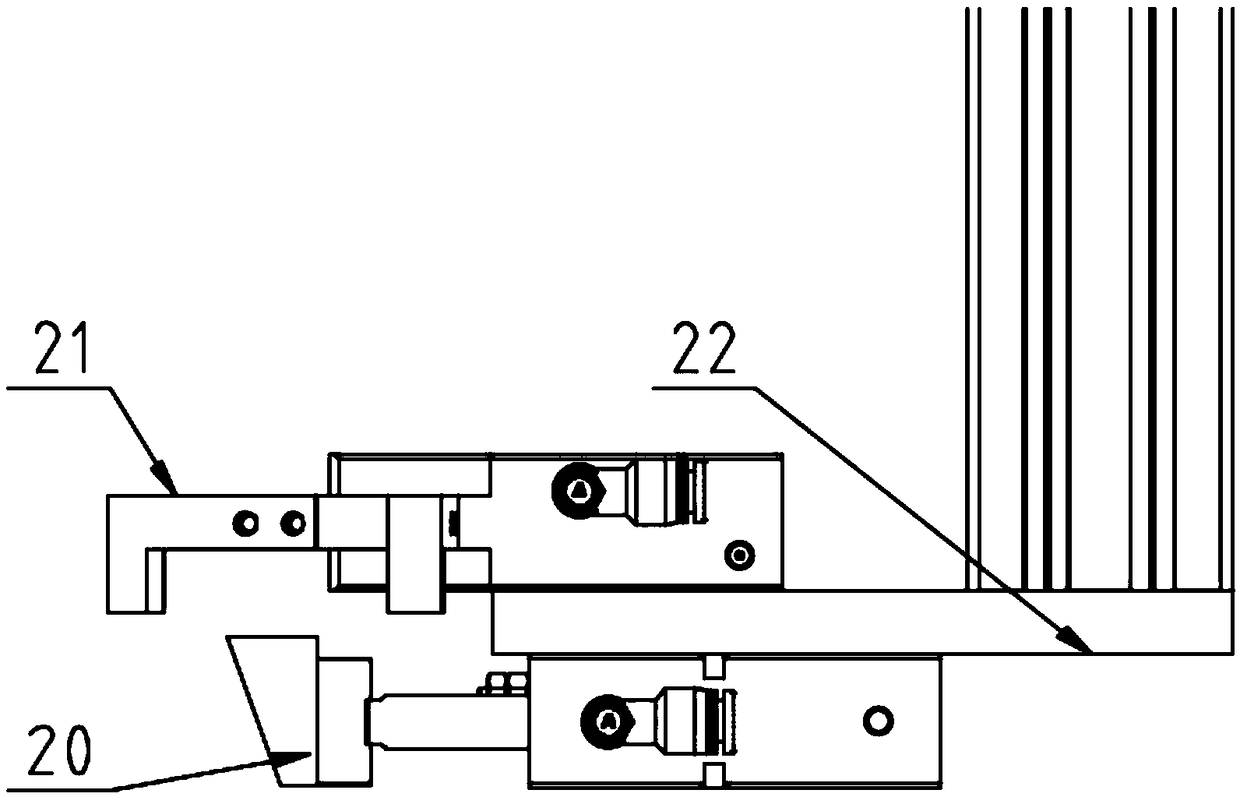

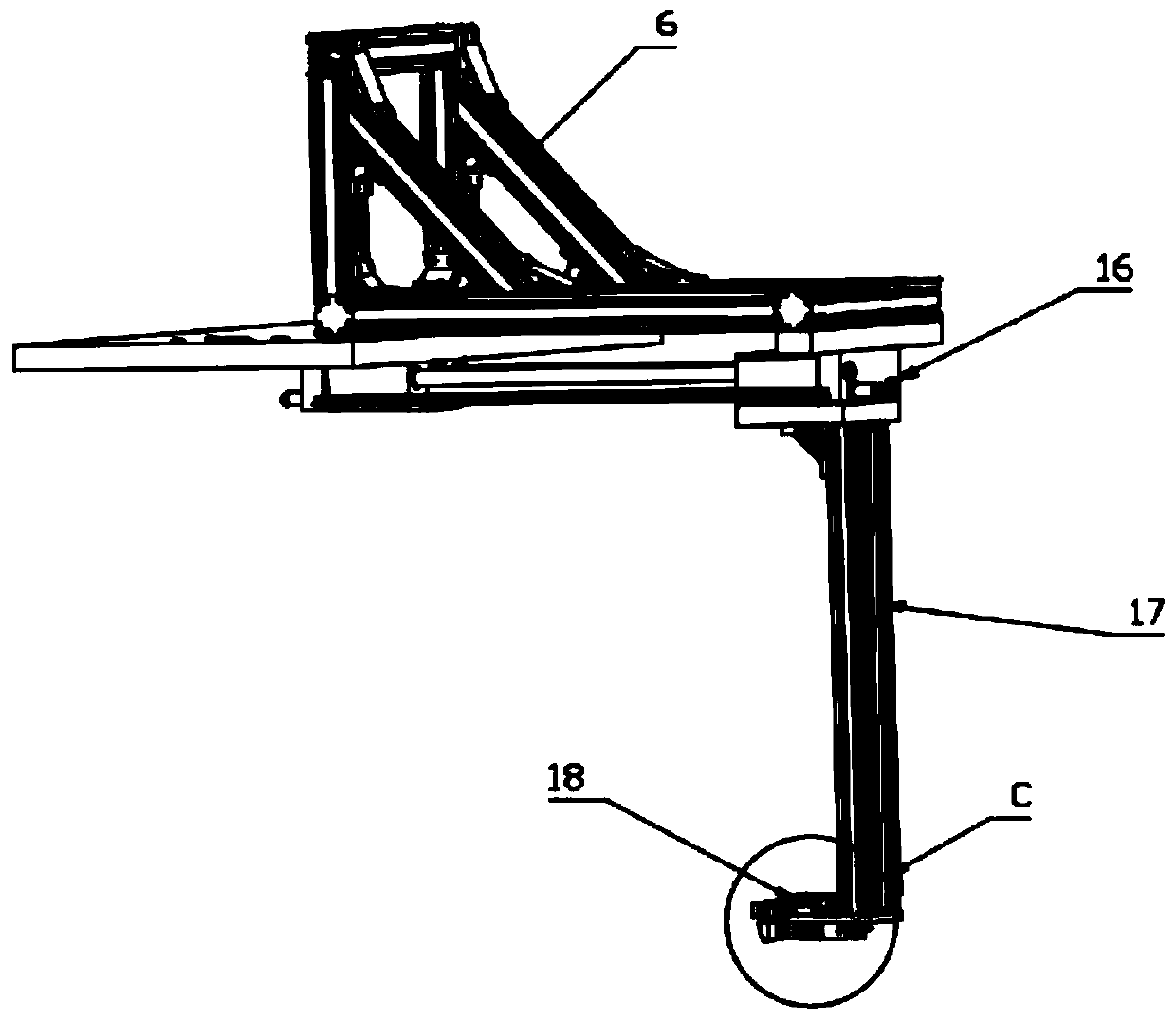

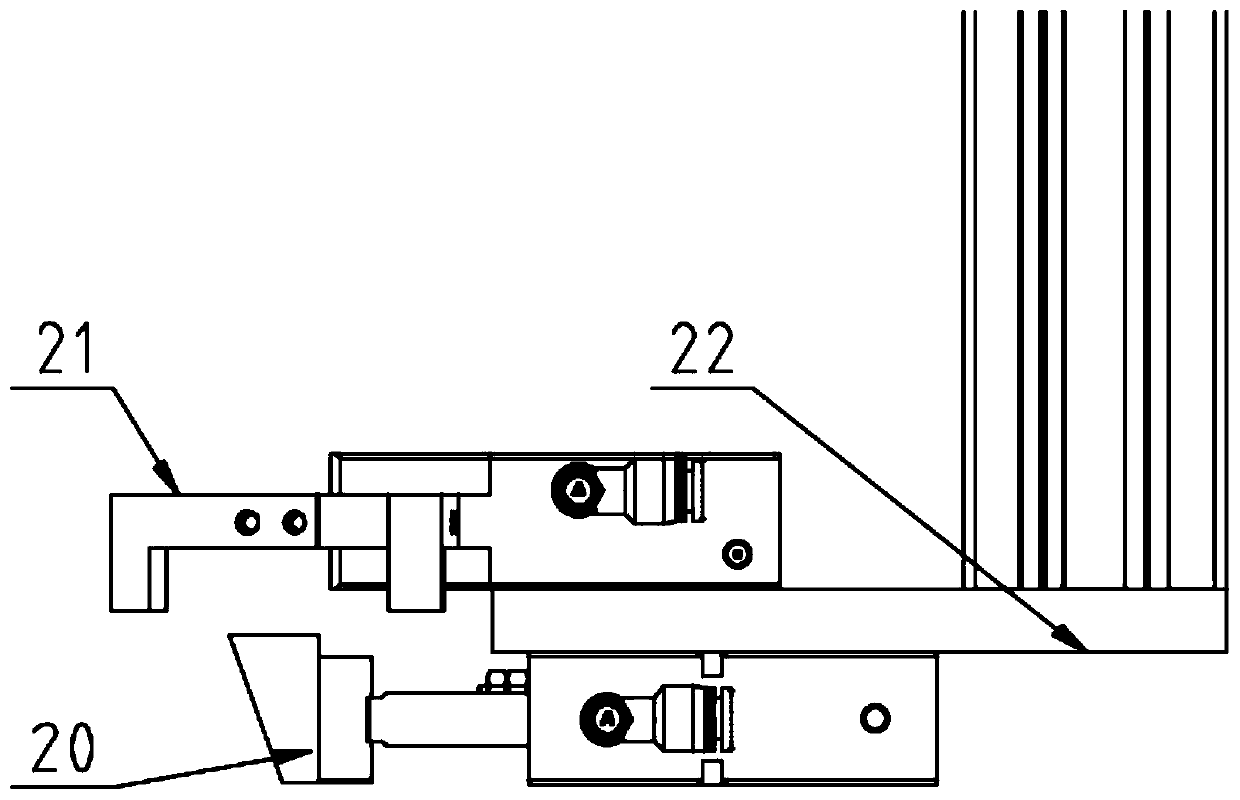

Automobile cylinder cover feeding and discharging device

InactiveCN108974917ARealize automatic feeding processNo manual operationConveyor partsEngineeringAssembly line

The invention discloses an automobile cylinder cover feeding and discharging device and belongs to the field of machine manufacturing. The automobile cylinder cover feeding and discharging device comprises a mounting frame, a rodless air cylinder, a connecting rod and a conveying gripper, wherein the conveying gripper comprises a push rod and a discharging rod, the discharging rod is arranged at the top of a mounting plate, and the push rod is arranged under the mounting plate. The automobile cylinder cover feeding and discharging device can be matched with an assembly line to achieve automatic feeding and discharging, save manual operation and achieve high safety.

Owner:北京宏远鑫瑞科技有限公司

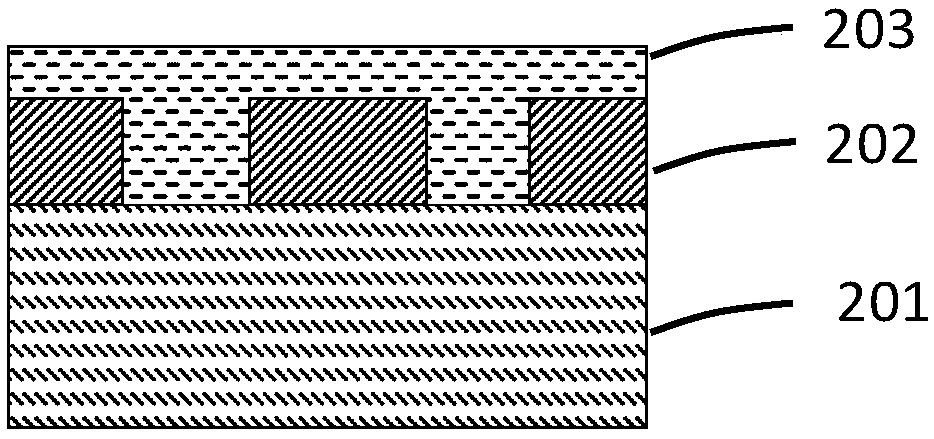

Controller, manufacturing method thereof, and monitoring method for chemical mechanical abrasive defects

ActiveCN109166812AEffective monitoringIncrease contrastSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingOptical scannersCompound (substance)

A control sheet is manufactured by forming a patterned first dielectric layer on an upper surface of a substrate and a second dielectric layer that fills grooves of at least the patterned first dielectric layer, and a method of manufacturing the control sheet and a method of monitoring chemical-mechanical polishing defects. The control sheet is placed on a chemical mechanical grinding machine andground for treatment to remove the first dielectric layer; Then, the surface of the treated control sheet is scanned to obtain defects of the upper surface of the control sheet to achieve monitoring of the chemical mechanical grinding defects. The control sheet provided by the invention improves the comparison degree between the defects on the surface of the control sheet and the background, further improves the grasping rate of the defects caused by the chemical mechanical polishing by the optical scanner table, and realizes the effective monitoring of the chemical mechanical polishing defects.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

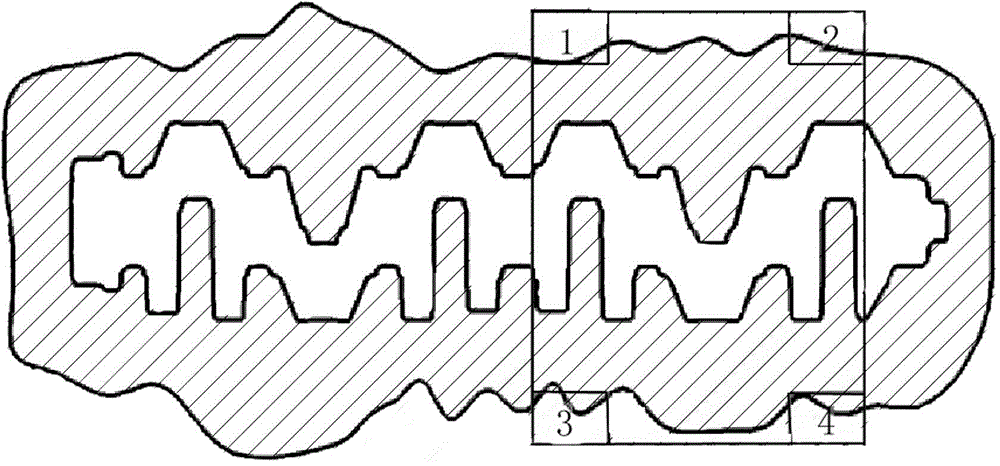

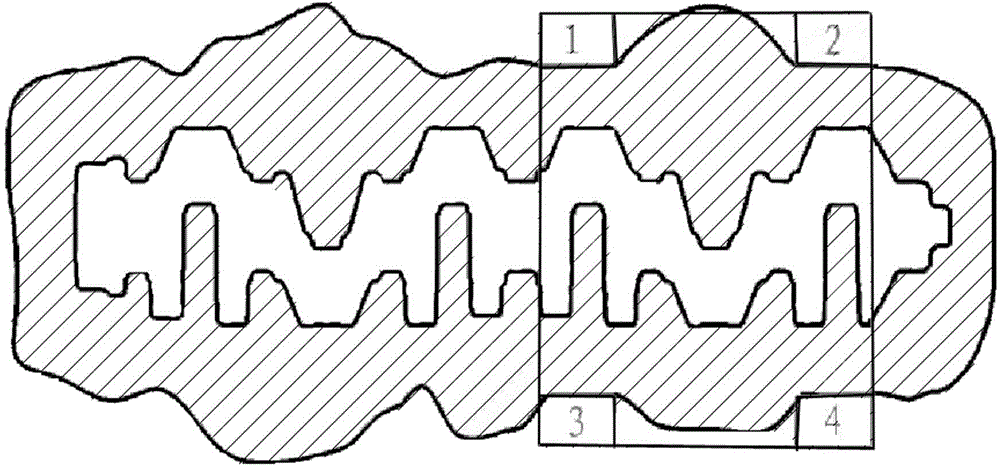

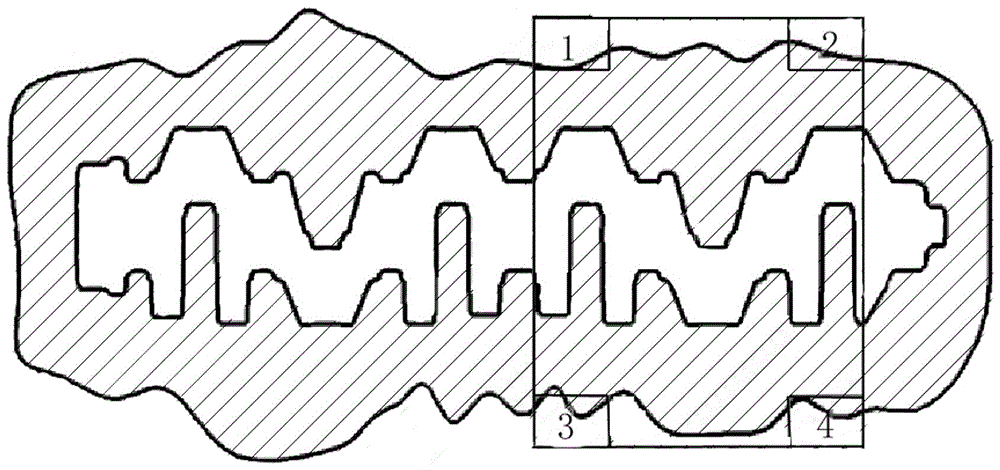

Molding technology for crankshaft forged piece flanges capable of being accurately grabbed by robot

The invention discloses a molding technology for crankshaft forged piece flanges capable of being accurately grabbed by a robot. The molding technology comprises the following steps: utilizing a CAE technology, stimulating and analyzing the shapes of pre-forged flanges and finish-forged flanges by using an FORGE software, determining the sizes of the flanges according to the shapes, designing the position of a flange positioning table, and finally molding the flanges. The technology has the advantages that the molding of the crankshaft forged piece flanges is stable, the accurate grabbing rate of the robot is high, fully-automatic forging is guaranteed, and the production profitability is substantially improved.

Owner:桂林福达重工锻造有限公司

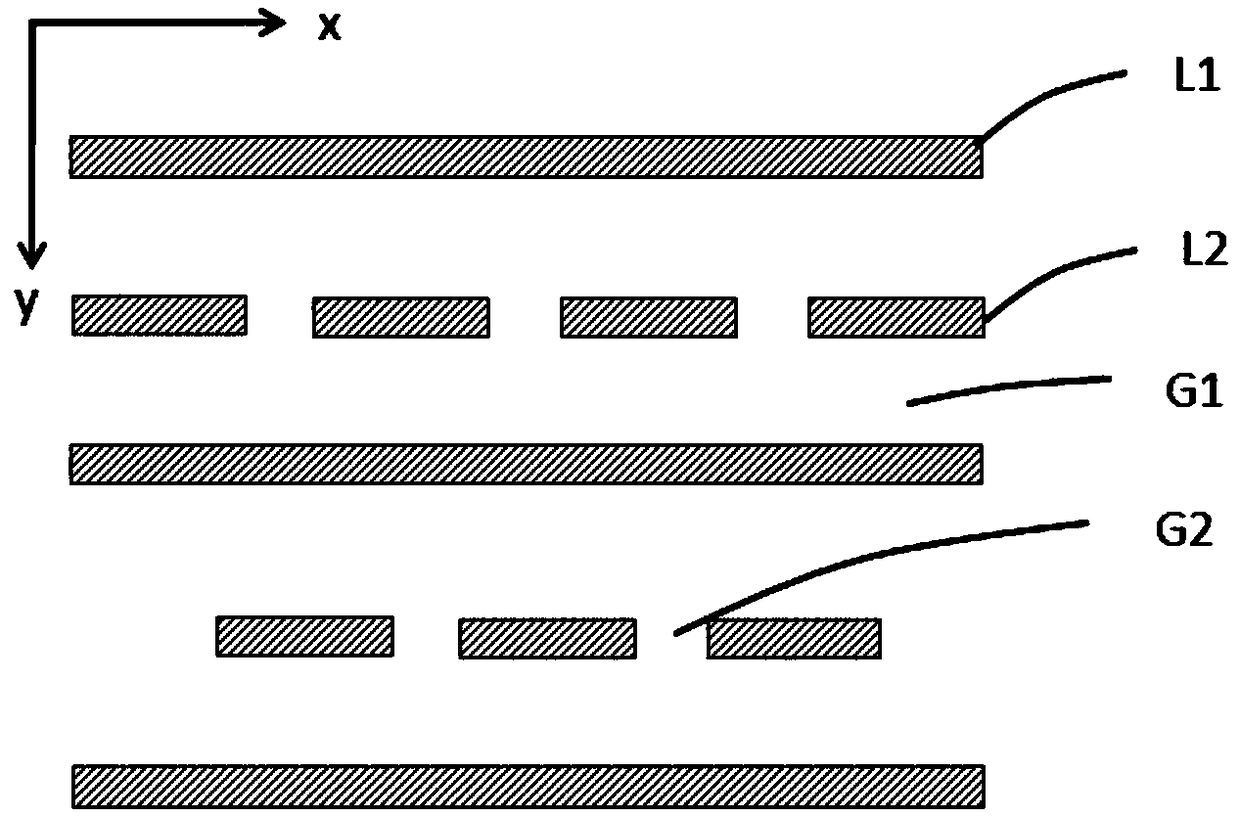

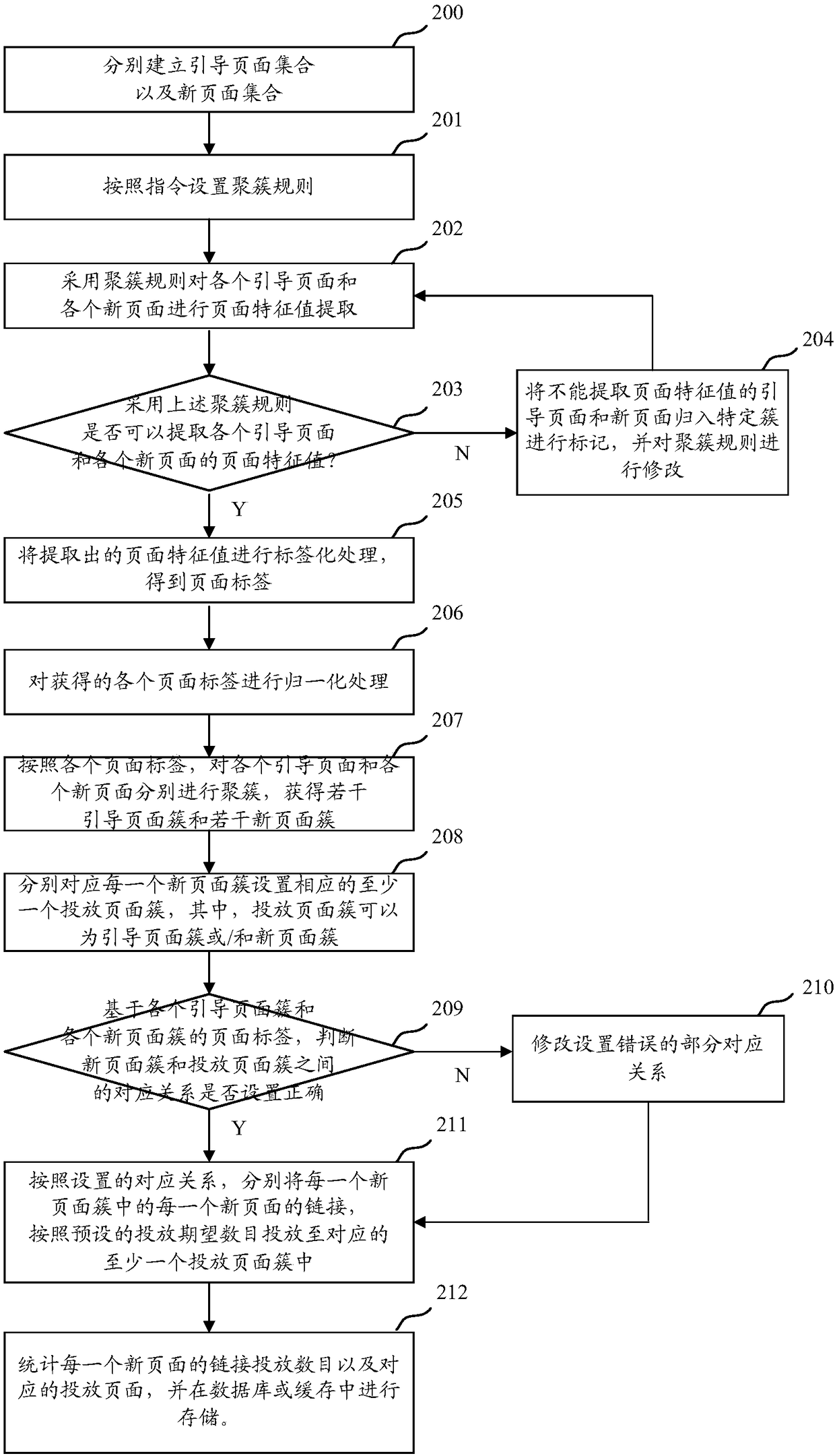

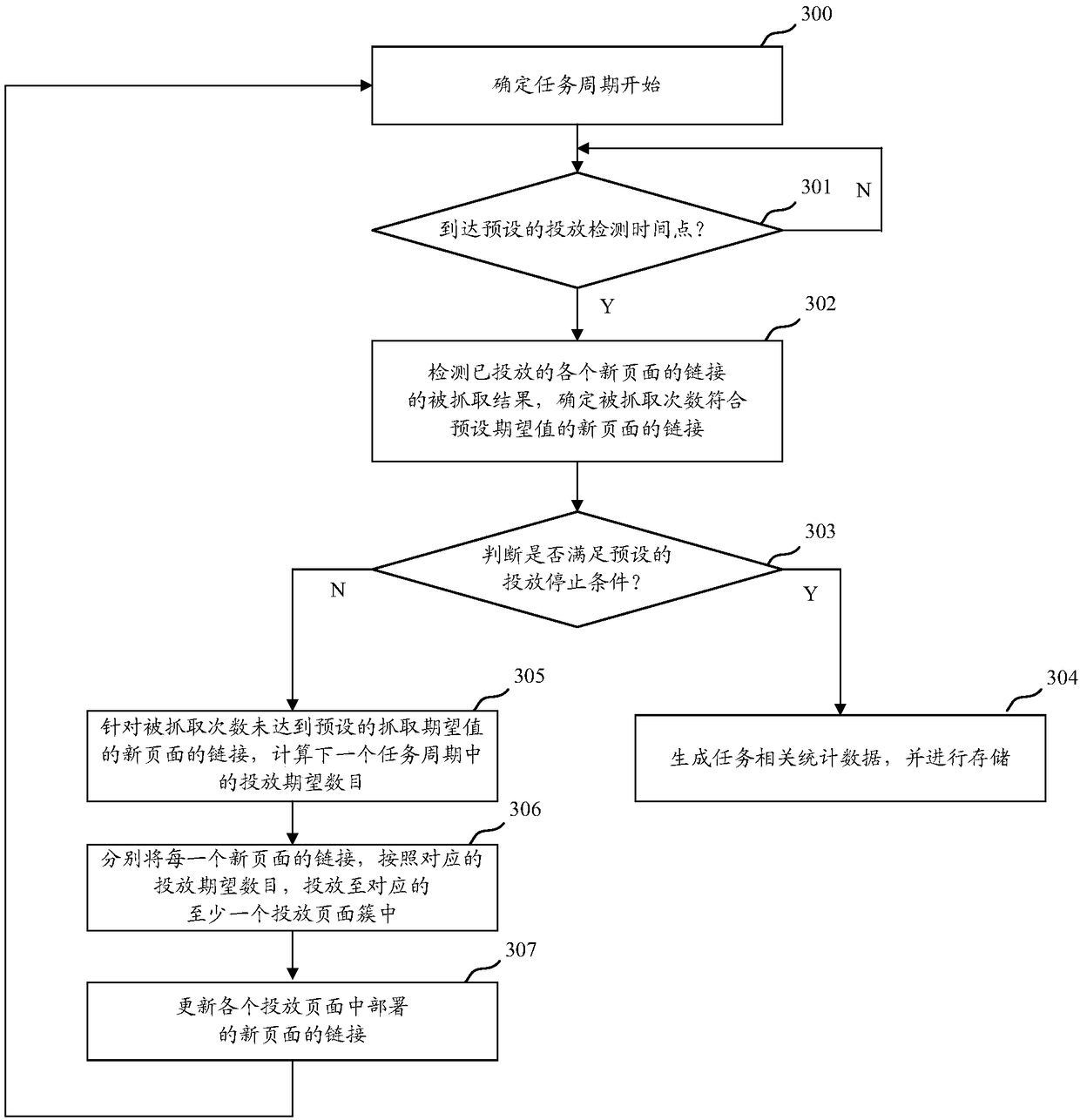

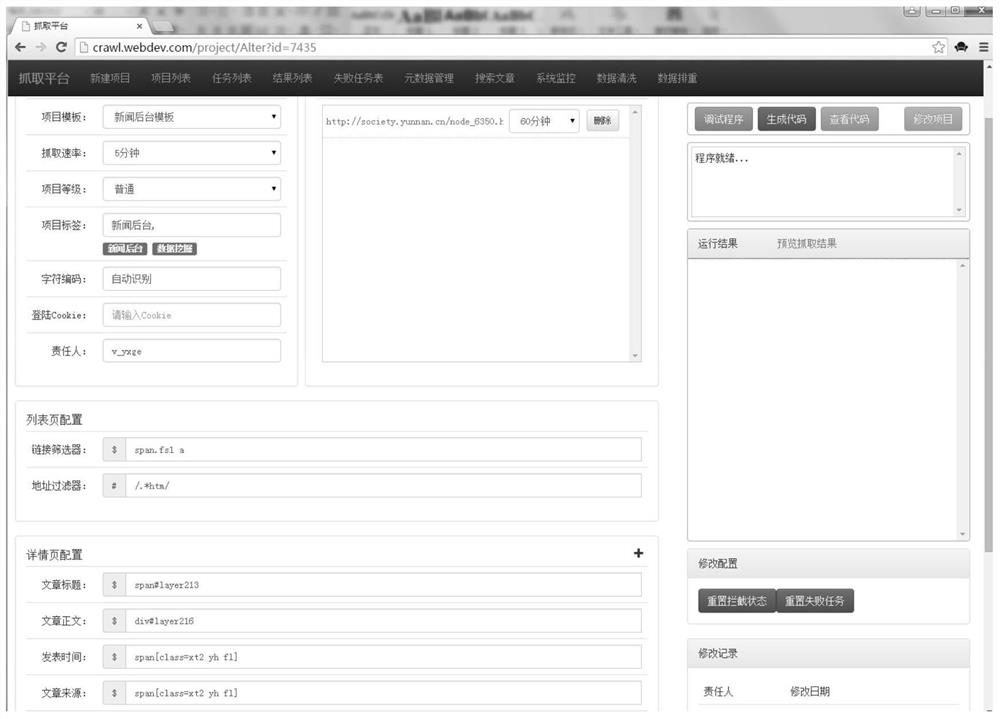

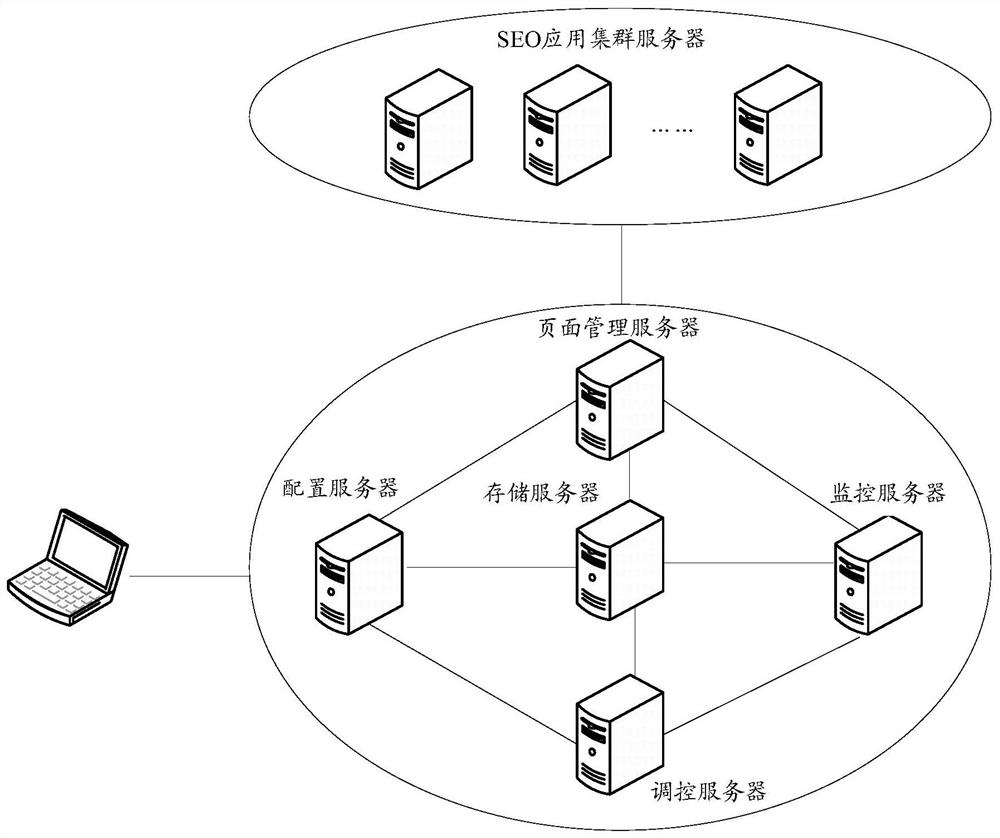

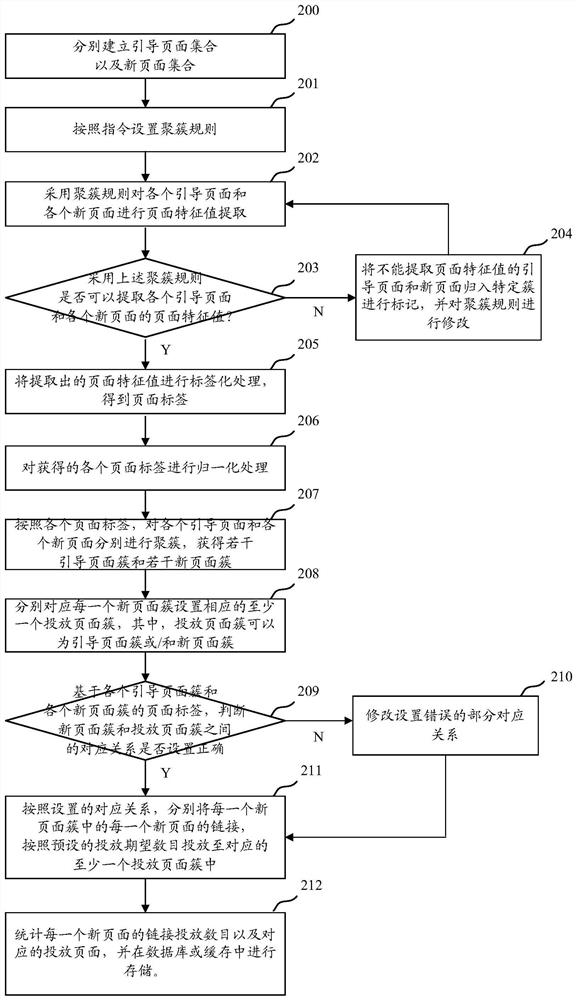

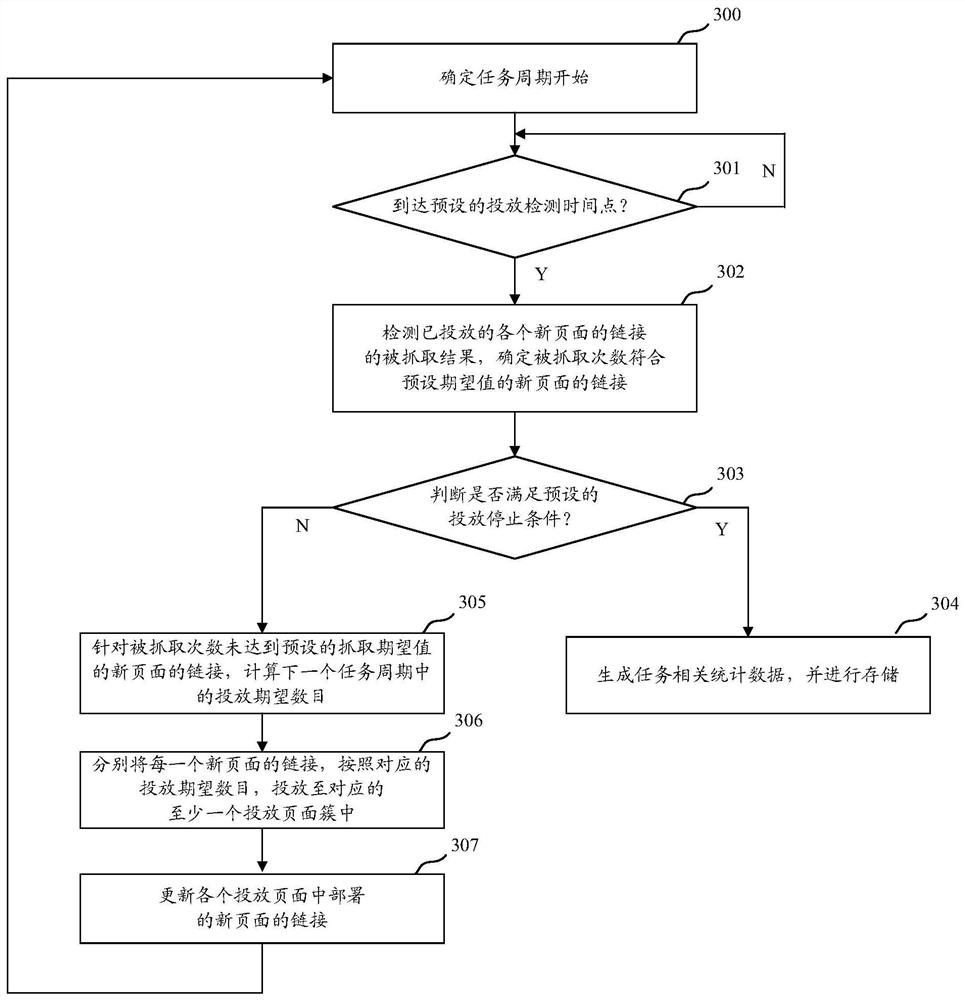

Page link releasing method and system and page link releasing adjustment method and system

ActiveCN108345615AImprove crawl rateReduce the crawl cycleCharacter and pattern recognitionWebsite content managementTraffic volumeInformation retrieval

The invention relates to network technologies, in particular to a page link releasing method and system and a page link releasing adjustment method and system, and aims at improving the new page capture rate. The page link releasing method comprises the following steps of: respectively clustering guiding pages and new pages to form a plurality of page clusters; and establishing a mapping relationship between the page clusters on the basis of content correlation, so as to ensure that links of the new pages are only released in the page clusters with the mapping relationship. According to the page link releasing method, the correlation between the new pages and other released pages is effectively improved; after capturing the released pages, a search engine is easy to further capture relatednew pages in the released pages on the basis of the content correlation, so that the new page capture rate can be greatly enhanced; and meanwhile, the content correlation between the new pages and the released pages accord with related rules of the search engine, so that capture weight values of the new pages are gradually accumulated and then flows can be imported from the search engine in a shortest time.

Owner:ALIBABA GRP HLDG LTD

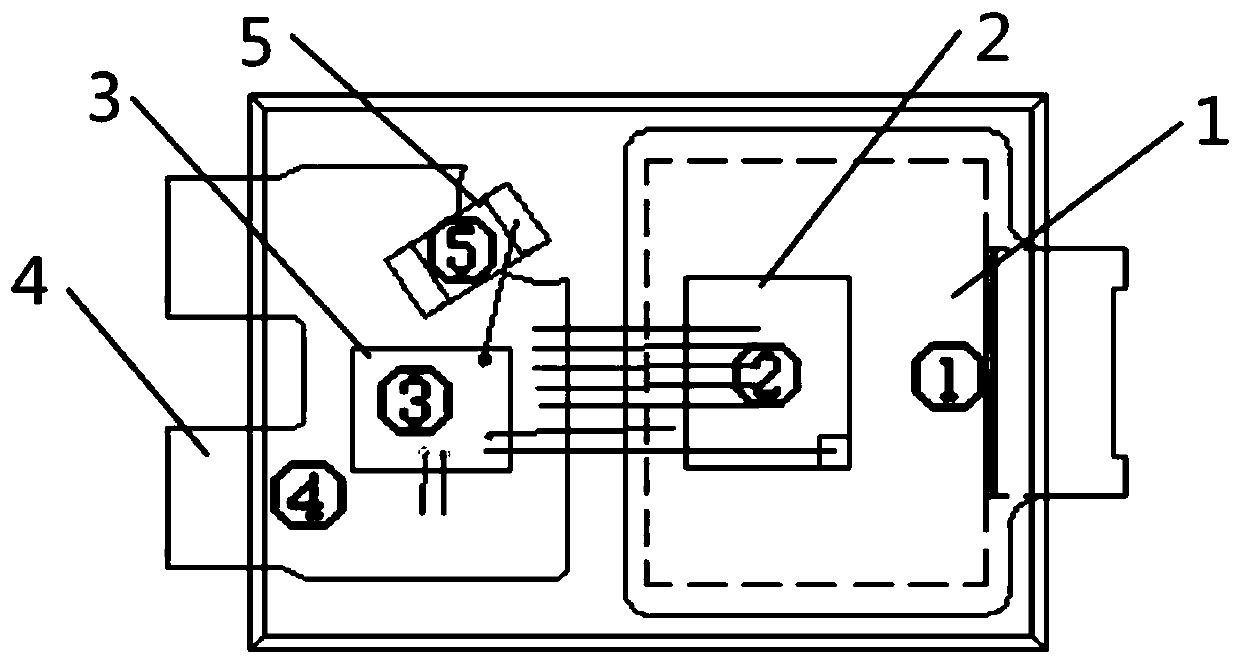

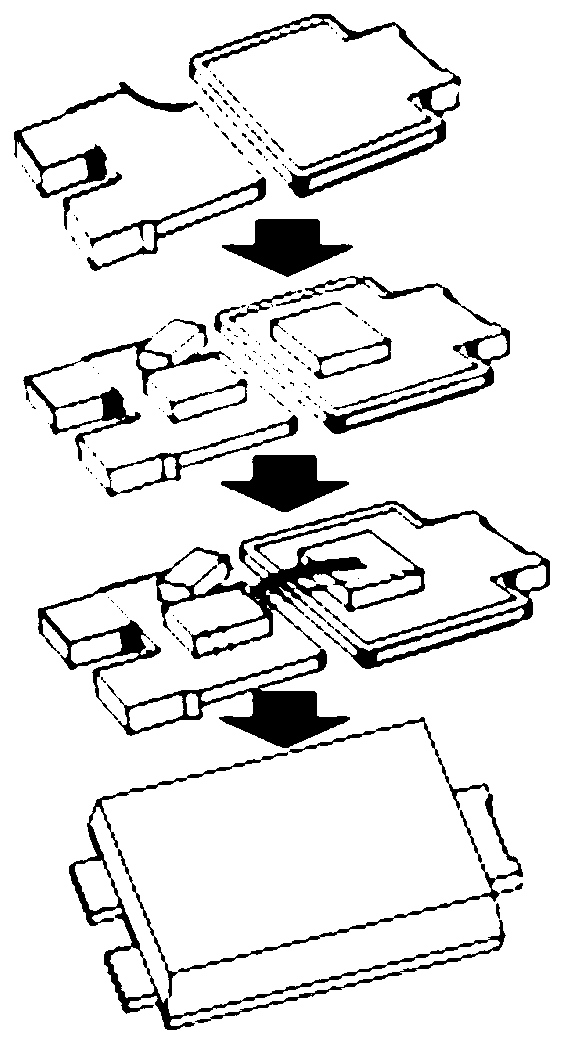

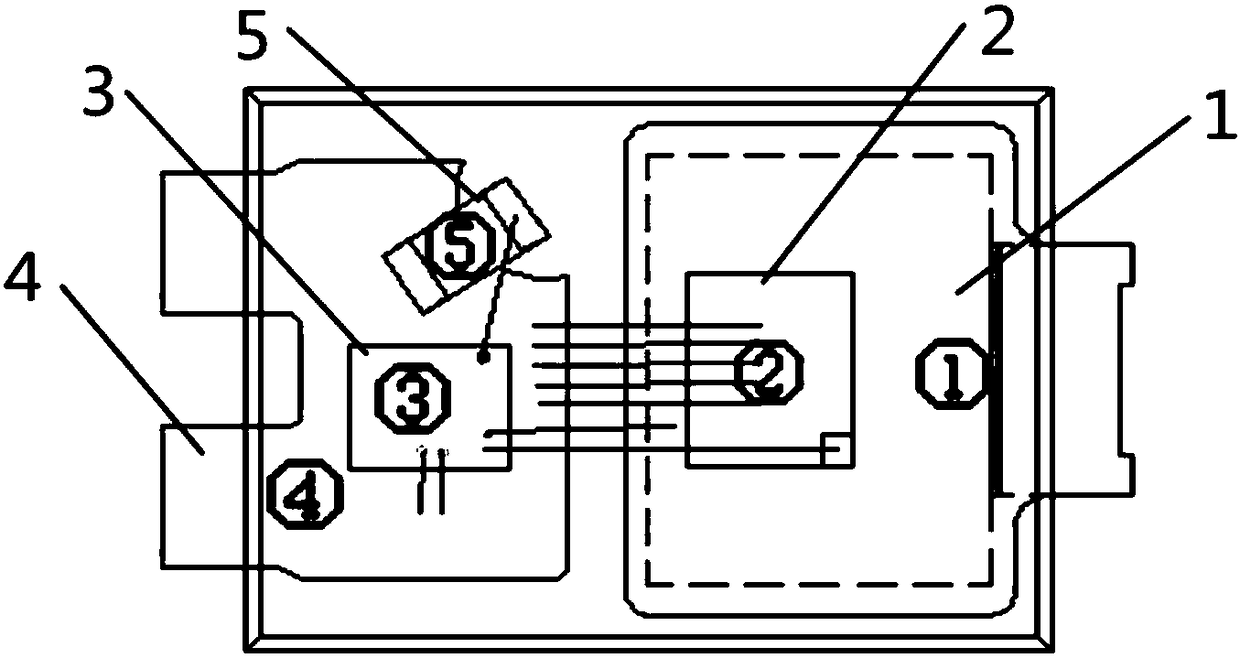

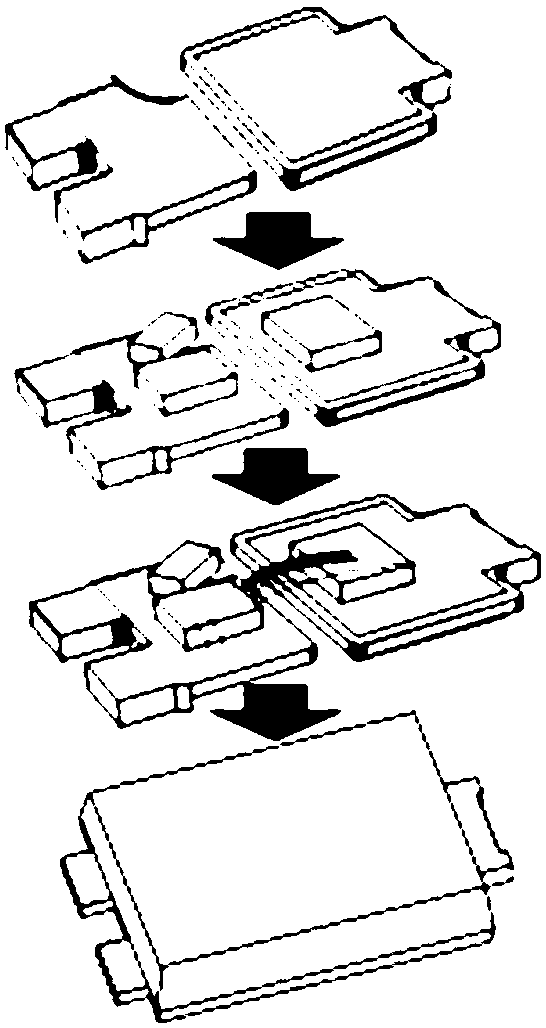

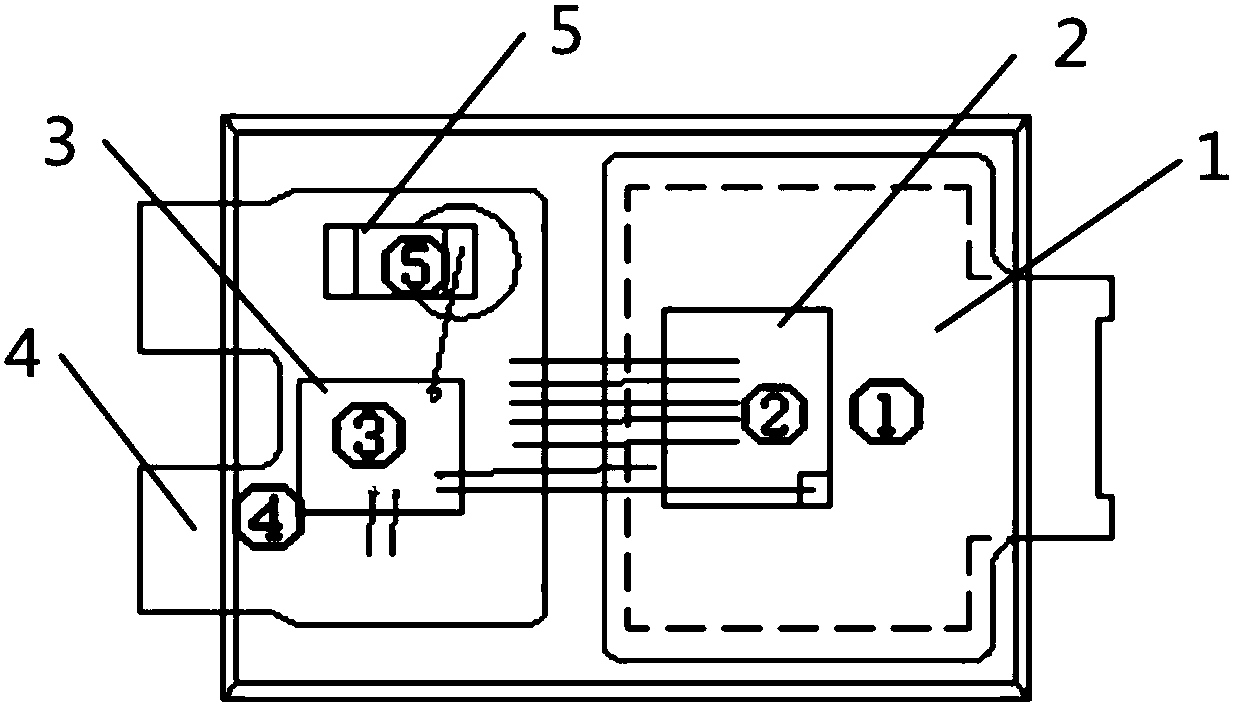

Two-chip synchronous rectifier diode

ActiveCN108281415BSmall sizeSimplify the installation processSemiconductor/solid-state device detailsSolid-state devicesCapacitanceMOSFET

The invention discloses a two-piece synchronous rectification diode, which comprises a first frame, a MOSFET chip, a control IC chip, a second frame, and a built-in capacitor. The second frame has two external pins, and the control IC chip is fixed on the second On the frame, the external terminal of the built-in capacitor is connected to the second frame; the first frame is provided with an external pin, and the MOSFET chip is fixed on the first frame; between the MOSFET chip and the control IC chip, between the control IC chip and the built-in Connections between internal terminals of the capacitor, between the MOSFET chip and the second frame, and between the control IC chip and the first frame are connected by bonding wires. The two-piece synchronous rectification diode optimizes the structure, integrates the available area of the PAD, and eliminates structural defects that may cause defects.

Owner:山东芯诺电子科技股份有限公司

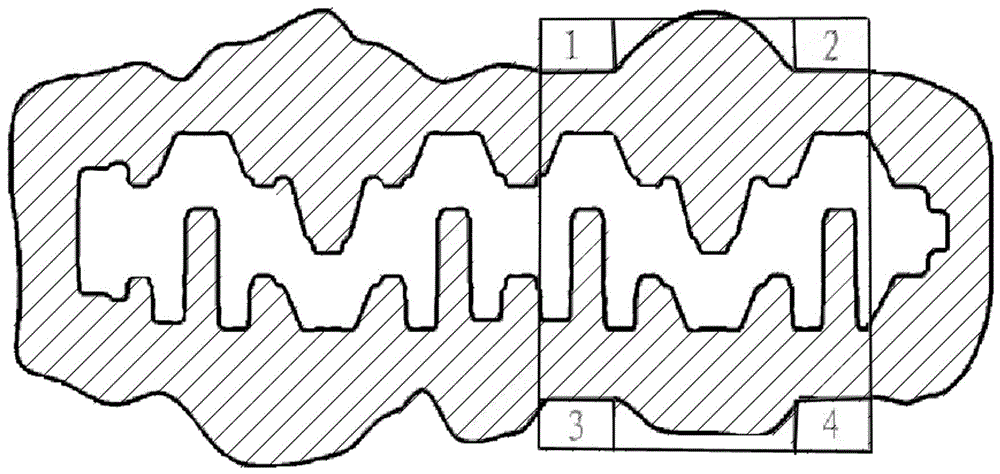

Full-flexible bionic pneumatic manipulator based on branch-imitating structure

A full-flexible bionic pneumatic manipulator based on a bionic branch structure comprises a pneumatic driving unit and manipulator units controlled independently, each manipulator unit comprises a shell with the overall shape of a bionic branch structure, and at least one surface of the shell in the length direction is of a zigzag structure; the inner part of the shell is provided with a cavity with a consistent shape, a strain limiting layer is also laminated on the surface of the shell at a position opposite to the zigzag structure, the shell and the strain limiting layer are both made of flexible materials, and the strain limiting layer is made of flexible materials of which the Young modulus is greater than that of the cavity; the shell and the cavity of the bionic branch structure are each composed of a first-stage main branch part and a plurality of stages of branch parts, the number of branches of the multiple stages of branch parts is gradually increased according to a preset rule, and the cavity of the branch of each branch part is connected with the pneumatic driving unit and is independent of the pneumatic driving unit. According to the robot, more types of objects can be stably, nondestructively and flexibly grabbed, the response time is shorter, the deformation process is faster, and the grabbing speed is higher.

Owner:ANHUI UNIVERSITY

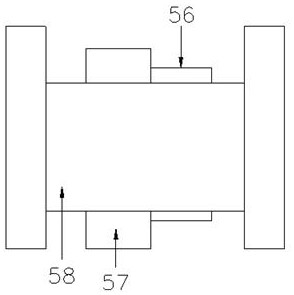

Grab bucket

InactiveCN111847234AFirmly connectedExpand the range of opening and closingCleaning using toolsLoad-engaging elementsElectric machineryEngineering

The invention relates to a grab bucket. The grab bucket comprises a pair of bucket bodies matched with each other, support rods are arranged at both ends of the bucket bodies, the other ends of the support rods are fixed to a mounting seat, the support rods are fixed through buffer rods, the buffer rods are connected with hydraulic rods, the hydraulic rods are connected with a fixing device, the fixing device is fixed to the bottom of the mounting seat, the side of the mounting seat is connected with the support rods through rotating shafts, limit blocks are arranged at both ends of the rotating shafts, cleaning devices are arranged on the fixing device, a motor is arranged on the mounting seat, and the motor is connected with a speed stabilizer. The grab bucket is high in degree of automation with compression resistance, shock absorption, wear resistance and rust prevention, work accuracy and efficiency are improved, and the opening range of the bucket bodies is further increased through the hydraulic rods; the use of hydraulic connecting rods and the combination of sprockets effectively strengthen the stability of the structure; the use of the cleaning devices can effectively strengthen cleaning of the bucket bodies, increase the accuracy of works, and avoid mixing of materials.

Owner:MAANSHAN ZHONGTIAN MACHINERY INSTALLED

A method to improve the capture rate of underetched defects

ActiveCN102938384BImprove crawl rateShorten the development cycleSemiconductor/solid-state device testing/measurementCopperComputer science

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

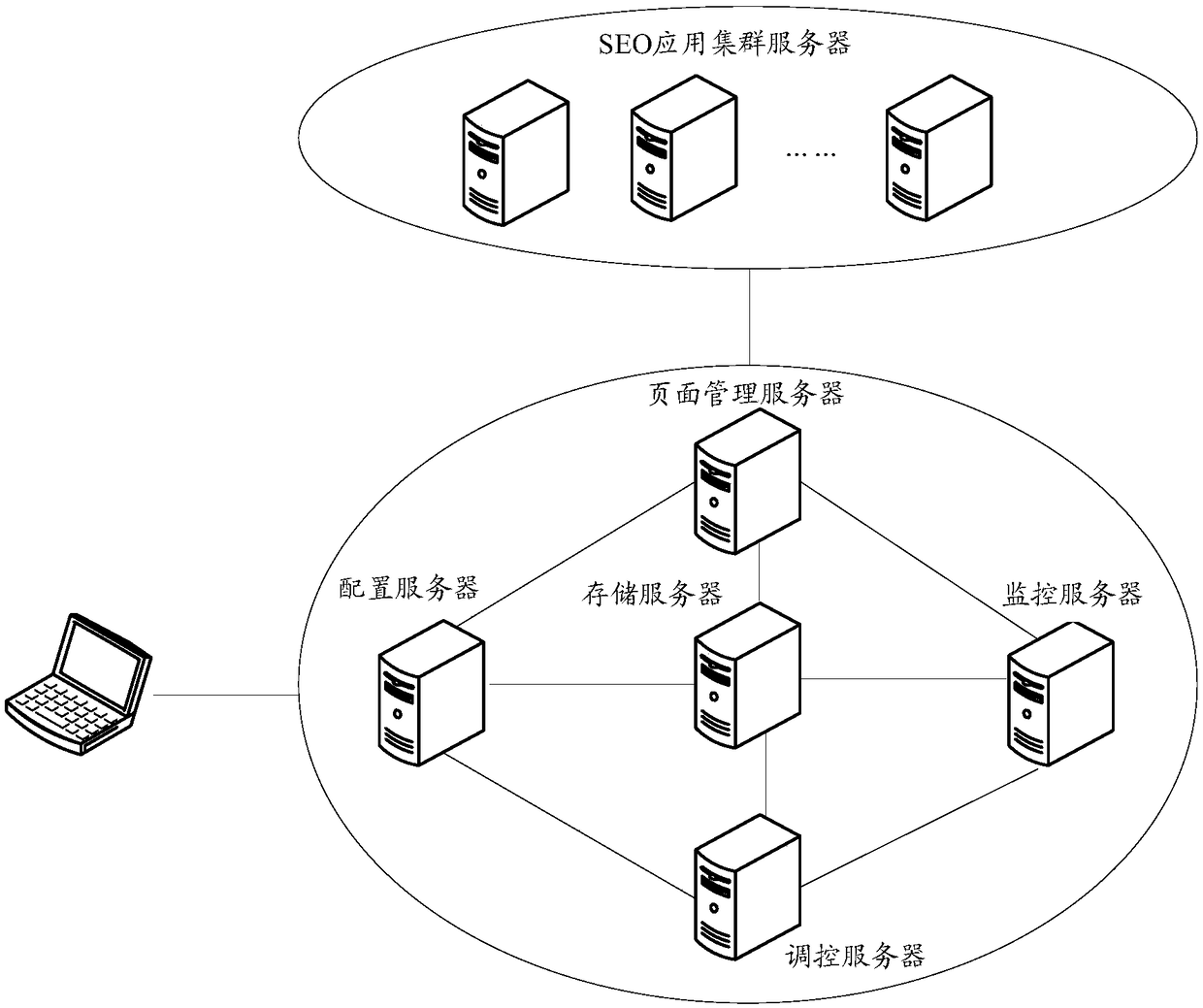

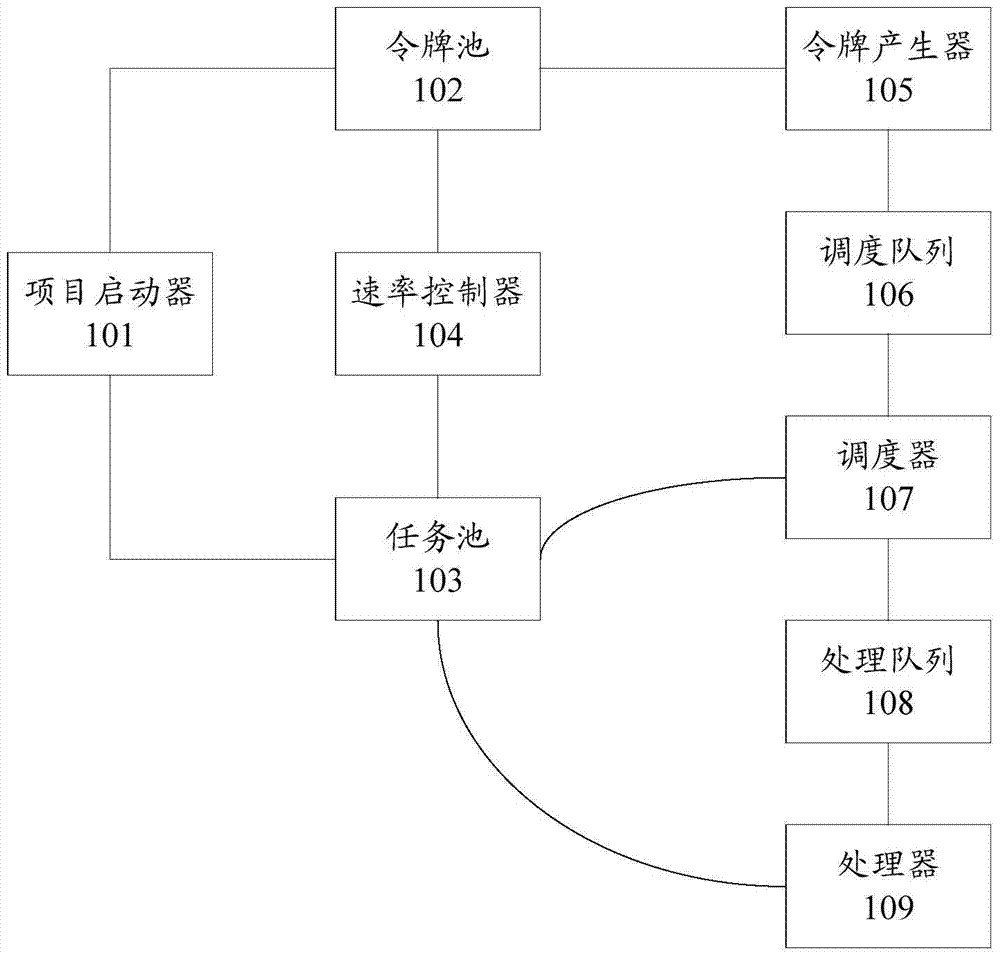

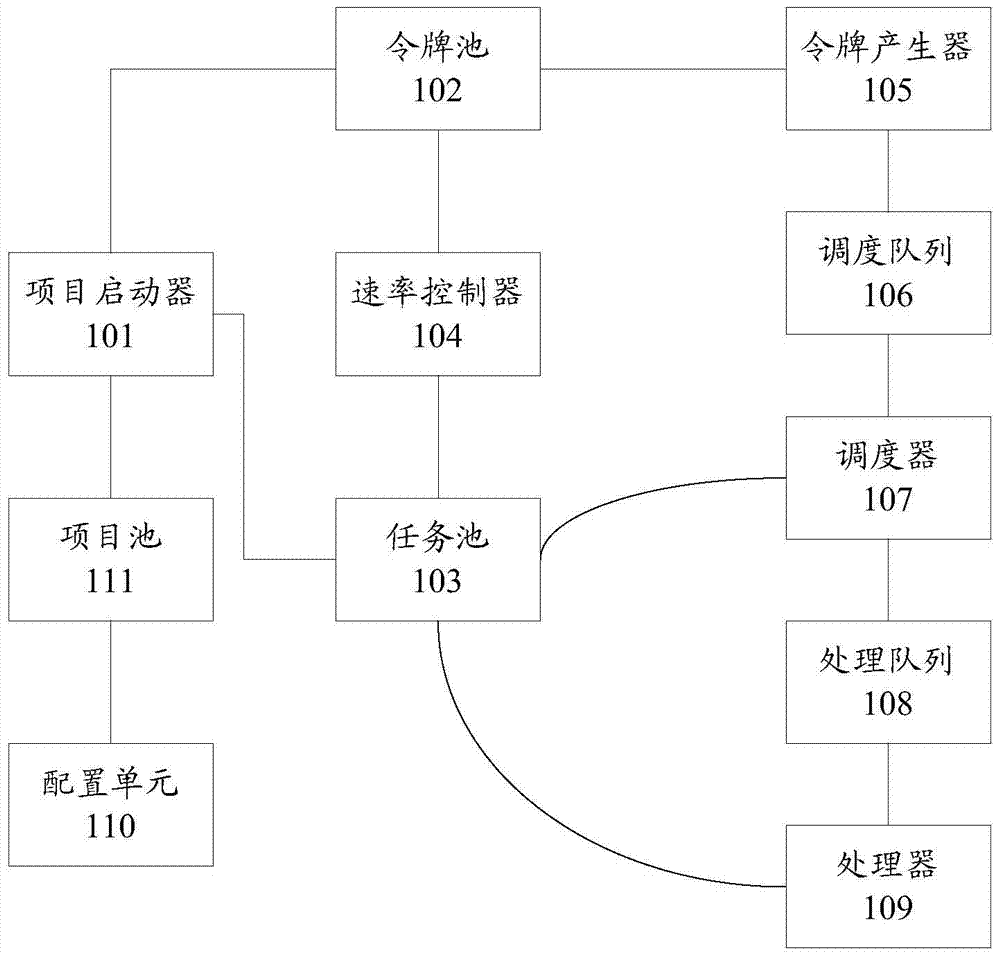

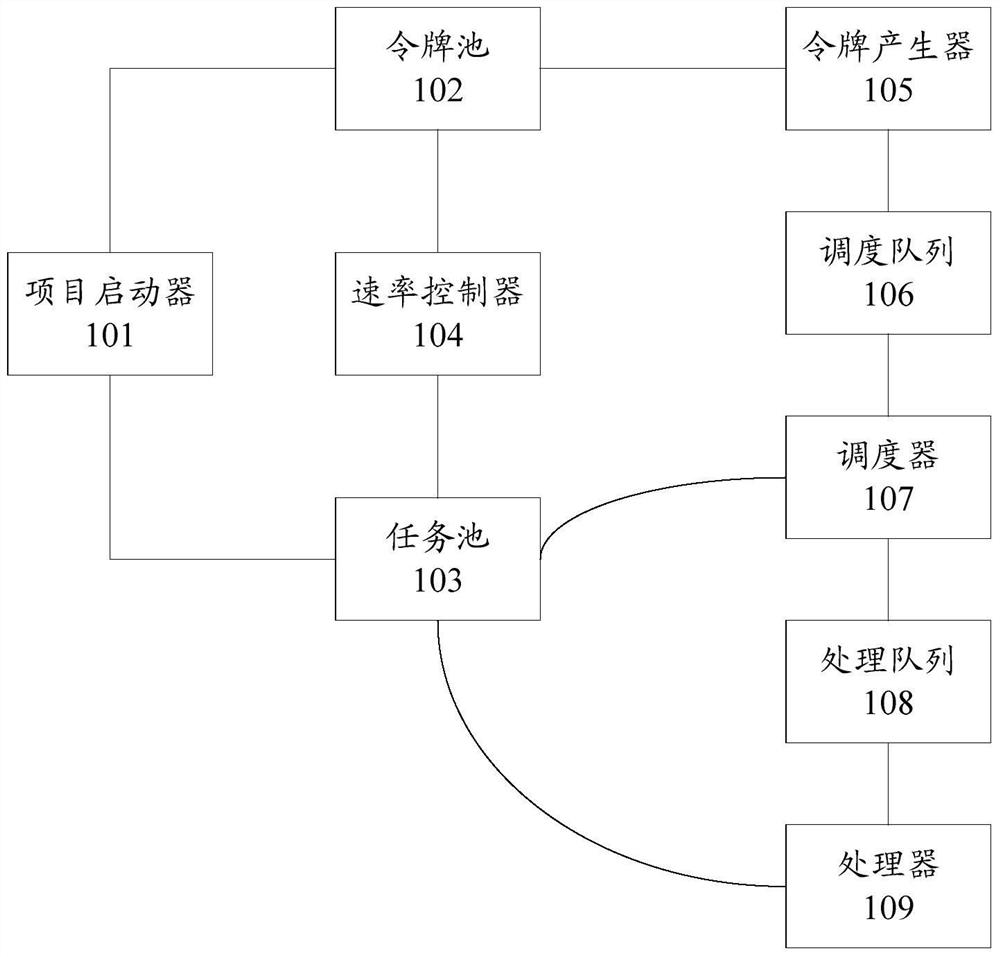

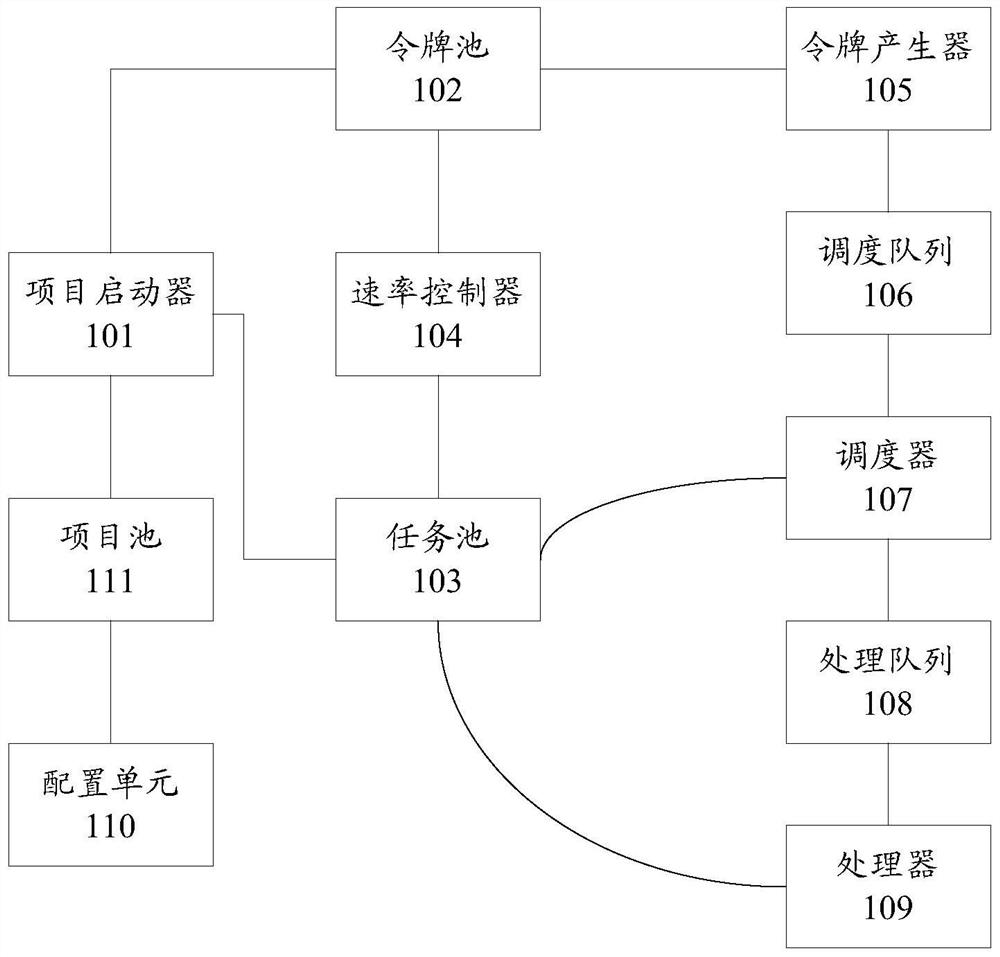

Information processing method and server

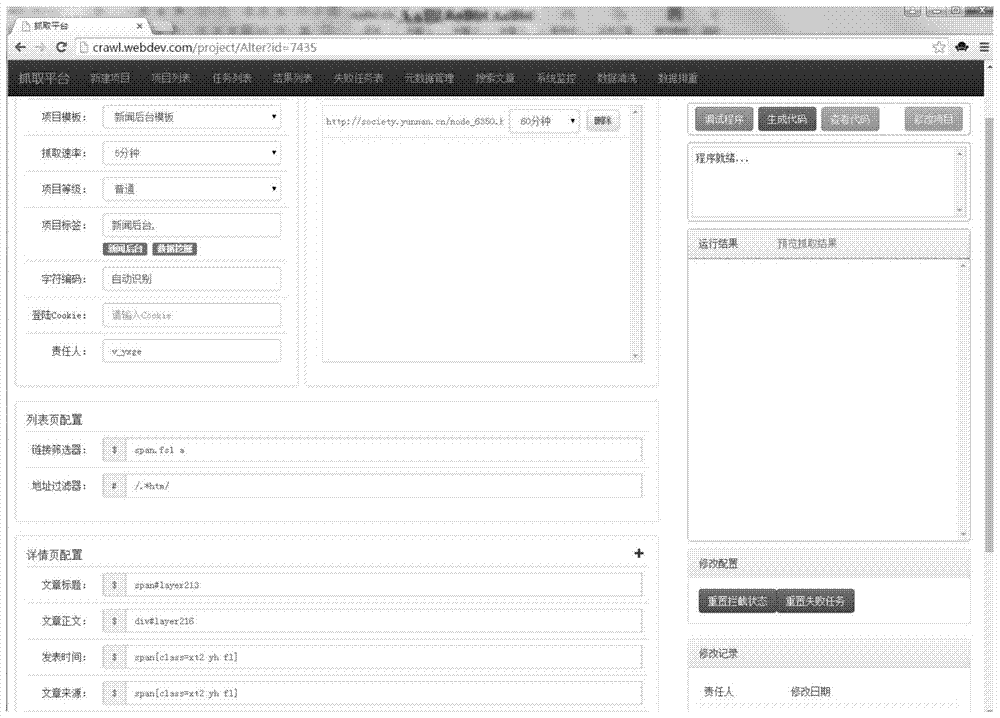

ActiveCN106982268APrevent being blockedAutomatic crawl rate adjustmentData switching networksInformation processingDomain name

The embodiment of the invention discloses an information processing method and a server. The method comprises the following steps: adding the task information to be subjected to data capture into a task pool; extracting the domain name information of the task information, generating tokens based on the domain name information, and adding the tokens into a token pool; determining the capture rate corresponding to the domain name information according to the number of the schedulable task information under the domain name information in the token pool; scanning the token pool, determining the number of the tokens corresponding to the domain name information based on the capture data, and when the number of the tokens meets the preset conditions, sending the corresponding number of the tokens to a scheduling queue; acquiring the tokens from the scheduling queue, selecting the first task information that meets the second preset conditions from the task pool based on the domain name information corresponding to the tokens, and adding the first task information to a processing queue; and extracting the first task information from the processing queue, and executing the capture of the corresponding data based on the first task information.

Owner:TENCENT TECH (BEIJING) CO LTD

A method for detecting insufficient etching of through holes

ActiveCN104091769BIncrease the number of viasImprove crawl rateSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTransmission gateComputer module

The invention discloses a method for detecting etching insufficiency of through holes. The method comprises the steps that a plurality of test modules are built on a semiconductor substrate, each test module simulates an SRAM device structure and comprises two simulation transmission gate transistors, two simulation pull-up transistors and two simulation pull-down transistors, the simulation transmission gate transistors, the simulation pull-up transistors and the simulation pull-down transistors are PMOS devices in an N well, and no grid electrode is formed on active areas of the simulation transmission gate transistors; a plurality of contacting holes are formed in each test module and filled with metal, and the contacting holes are at least connected with positions, corresponding to grid electrodes, in the active areas of the simulation transmission gate transistors; a metal interconnection line and a conduction through hole are formed on each contacting hole; the test modules are scanned through an electron beam defect scanner under a positive potential condition, and the etching insufficiency defects of the through holes of the test modules are detected according to the image feature pictures obtained through scanning. The method for detecting etching insufficiency of the through holes can effectively improve the capturing efficiency of the etching insufficiency defects.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Two-piece synchronous rectification diode

ActiveCN108281415ASmall sizeSimplify the installation processSemiconductor/solid-state device detailsSolid-state devicesCapacitanceMOSFET

The invention discloses a two-piece synchronous rectification diode. The two-piece synchronous rectification diode comprises a first framework, a metal-oxide-semiconductor field-effect transistor (MOSFET) chip, a control IC chip, a second framework and a built-in capacitor, wherein the second framework is provided with two external pins, the control IC chip is fixed on the second framework, the second framework is connected with an external wiring end of the built-in capacitor, the first framework is provided with an external pin, the MOSFET chip is fixed on the first framework, and the MOSFETchip and the control IC chip, the control chip and an internal wiring end of the built-in capacitor, the MOSFET chip and the second framework and the control chip and the first framework are connected by bonding wires. By the two-piece synchronous rectification diode, the structure is optimized, the available area of a PAD is integrated, and unfavorable structure defect easy to cause is removed.

Owner:山东芯诺电子科技股份有限公司

A Crankshaft Forging Flash Shaping Process Adaptable to Accurate Grasping by Robots

The invention discloses a molding technology for crankshaft forged piece flanges capable of being accurately grabbed by a robot. The molding technology comprises the following steps: utilizing a CAE technology, stimulating and analyzing the shapes of pre-forged flanges and finish-forged flanges by using an FORGE software, determining the sizes of the flanges according to the shapes, designing the position of a flange positioning table, and finally molding the flanges. The technology has the advantages that the molding of the crankshaft forged piece flanges is stable, the accurate grabbing rate of the robot is high, fully-automatic forging is guaranteed, and the production profitability is substantially improved.

Owner:桂林福达重工锻造有限公司

Method for Detecting Via Underetch and Via Missing Defects

ActiveCN103367192BImprove crawl rateImprove yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetal silicideProcess manufacturing

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Website link detection method and system

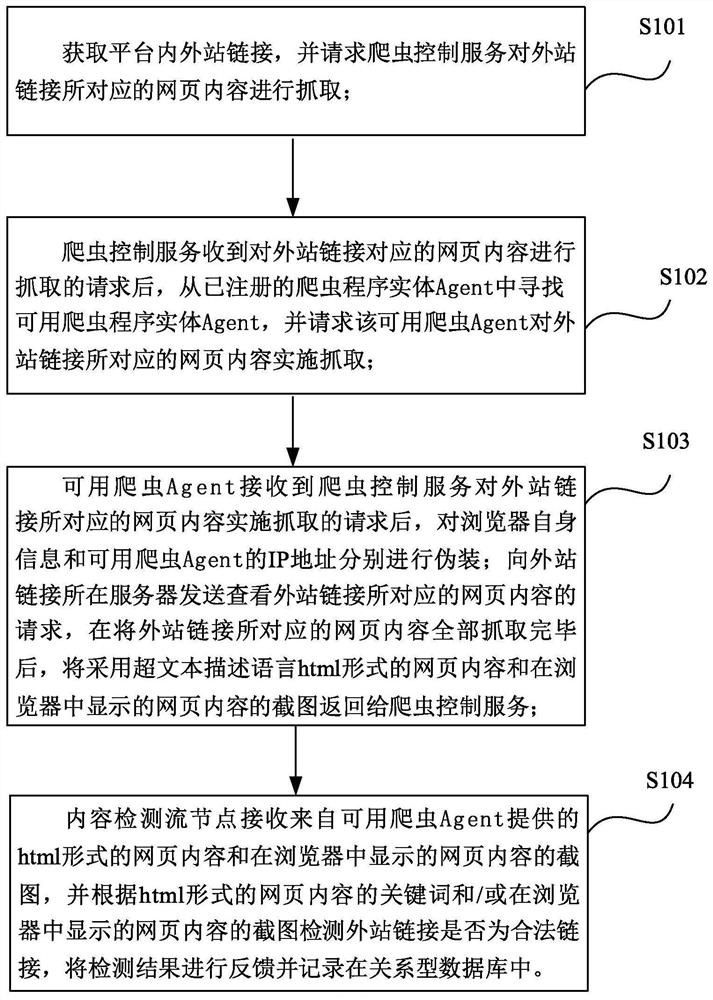

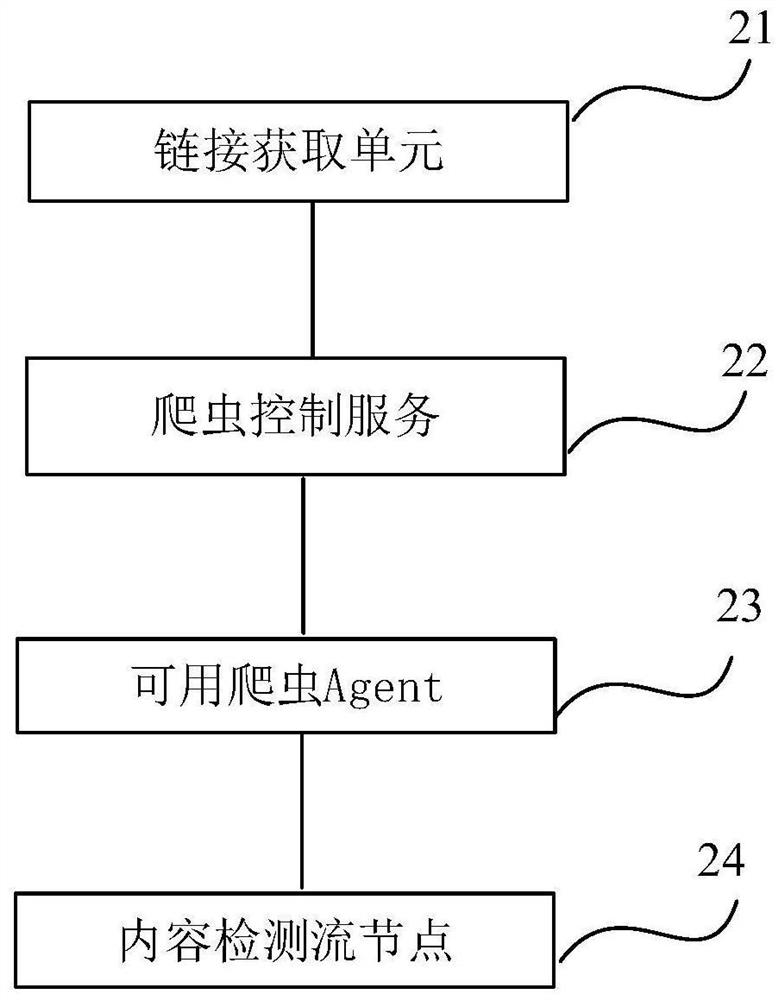

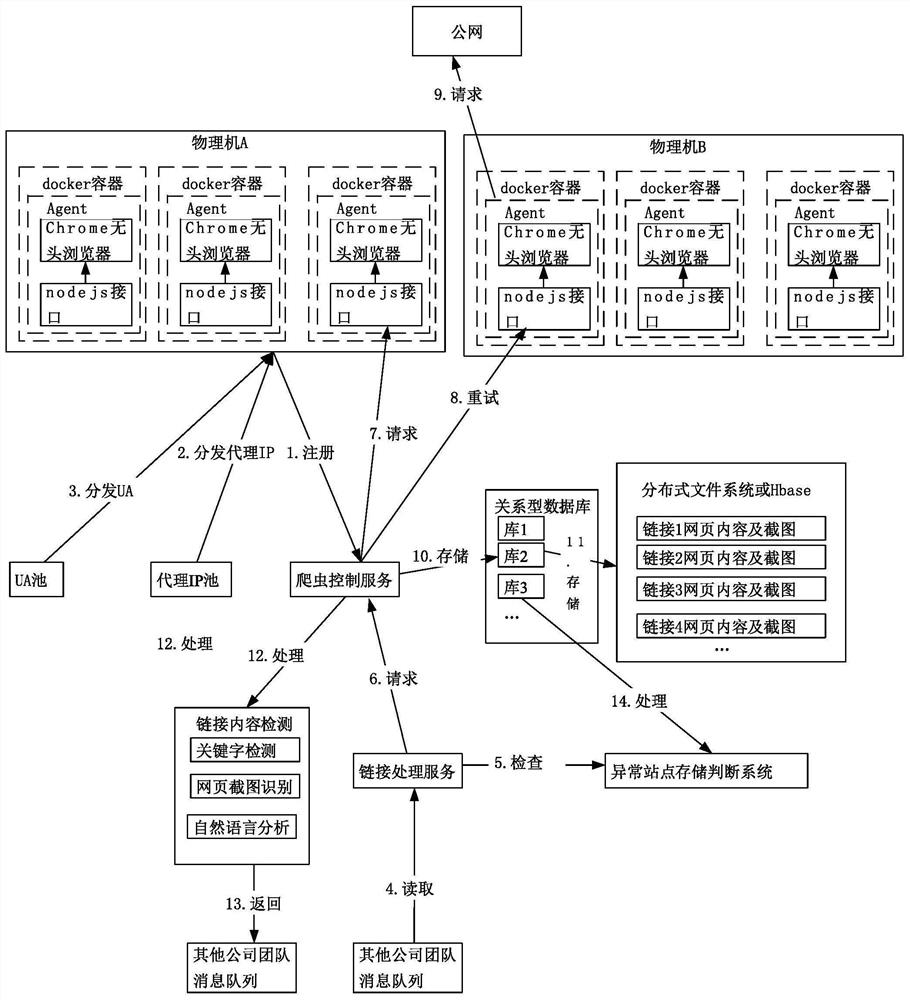

PendingCN113505287AReal-time detectionImprove crawl rateWeb data indexingSpecial data processing applicationsWeb siteIp address

The embodiment of the invention provides a website link detection method and system. The website link detection method comprises the steps that an external website link published in a platform is obtained, and webpage content corresponding to the external website link is requested to be grabbed; the crawler control service searches for an available crawler program entity Agent and requests to capture webpage content corresponding to the foreign site link; the available crawler Agent camouflages the information of the browser and the IP address of the available crawler Agent; after all webpage contents corresponding to the external website link are captured, returning the webpage contents and screenshots of the webpage contents to the crawler control service; and the content detection stream node detects whether the foreign site link is a legal link or not according to the keyword of the webpage content in the html form and / or the screenshot of the webpage content displayed in the browser. The external station link can be detected in real time, and the capturing rate of the external station link is high, so that normal release of the legal external station link can be ensured, and the detection efficiency is high.

Owner:MICRO DREAM TECHTRONIC NETWORK TECH CHINACO

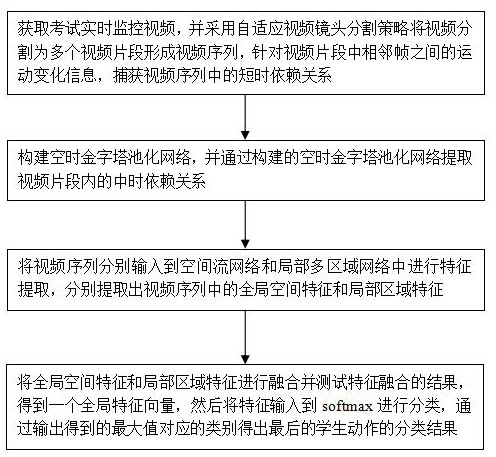

Examination illegal behavior detection method based on 3D convolution

PendingCN113850119ASolve needsSolve the costImage enhancementImage analysisFeature vectorArea network

The invention discloses an examination illegal behavior detection method based on 3D convolution, and the method comprises the following steps: segmenting an examination real-time monitoring video into a plurality of video segments to form a video sequence, and capturing a short-time dependency relationship in the video sequence; extracting a medium-time dependency relationship in the video clip through the constructed space-time pyramid pooling network; respectively inputting the video sequence into a spatial stream network and a local multi-area network for feature extraction, and respectively extracting global spatial features and local area features; fusing the global spatial features and the local region features and testing a feature fusion result to obtain a global feature vector, inputting the global feature vector into softmax for classification, and obtaining a classification result of student actions. According to the invention, the manpower resource consumption and the time cost required by the playback of the examination monitoring video can be greatly reduced, the continuous illegal behaviors of the examinee in the examination room can be analyzed, and the capturing efficiency of the illegal behaviors is improved.

Owner:四川天翼网络股份有限公司

Hooking conveying type fruit picker

The invention relates to the field of fruit picking, in particular to a hooking conveying type fruit picker which comprises a picking head portion, a telescopic control device and a supporting device.The picking head portion and the telescopic control device are both fixedly connected with a main rod. The supporting device is connected with the main rod through a main supporting rod. Two hookingclaws fixed to a belt wheel on the picking head portion rotate along with the belt wheel so as to hook fruit stems on trees into the picker, a small round saw web is driven by a high-speed motor to cut off the fruit stems and the fruits are conveyed to the tail end of the picking head portion, the height of the picking head portion is controlled by controlling the distance of the operation handleto control the advancing and retreating of the picking head portion and adjust the rotation of an operation handle in the whole picking operation, and the all-directional control over the picking headportion is realized. The problem that an existing fruit picker is low in grabbing accuracy and prone to damaging the surfaces of the fruits and cannot conduct continuous picking is solved.

Owner:NANCHANG UNIV

An information processing method and server

ActiveCN106982268BPrevent being blockedAutomatic crawl rate adjustmentData switching networksDomain nameInformation processing

The embodiment of the present invention discloses an information processing method and server, including: adding the task information to be captured into the task pool; extracting the domain name information of the task information, generating a token according to the domain name information, and Add the token to the token pool; determine the capture rate corresponding to the domain name information according to the amount of task information that can be scheduled under the domain name information in the token pool; scan the token pool, according to the The capture rate determines the number of tokens corresponding to the domain name information, and when the number of tokens meets the preset conditions, sends the corresponding number of tokens to the scheduling queue; obtains tokens from the scheduling queue, according to the The domain name information corresponding to the token selects the first task information that meets the second preset condition in the task pool, and adds the first task information to the processing queue; extracts the first task information from the processing queue Task information, executing corresponding data capture according to the first task information.

Owner:TENCENT TECH (BEIJING) CO LTD

A method and system for delivering and delivering a page link

ActiveCN108345615BImprove crawl rateReduce the crawl cycleCharacter and pattern recognitionWebsite content managementEngineeringDatabase

The present application relates to network technology, in particular to a method and system for placing and adjusting page links, which are used to increase the crawling rate of new pages. The method is as follows: respectively cluster the guide page and the new page to form multiple page clusters, establish a mapping relationship between each page family based on content correlation, and ensure that the link of the new page is only placed in the mapped page cluster, In this way, the correlation between the new page and other delivery pages is effectively improved. After the search engine captures the delivery page, it is easy to further capture relevant new pages in the delivery page based on the content relevance, which can greatly improve Improve the crawling rate of new pages; at the same time, because there is content correlation between the new page and the delivery page, which is in line with the relevant rules of the search engine, the crawled weight of the new page will gradually accumulate, so that it can be retrieved in the shortest possible time. Introduce traffic from search engines within a short period of time.

Owner:ALIBABA GRP HLDG LTD

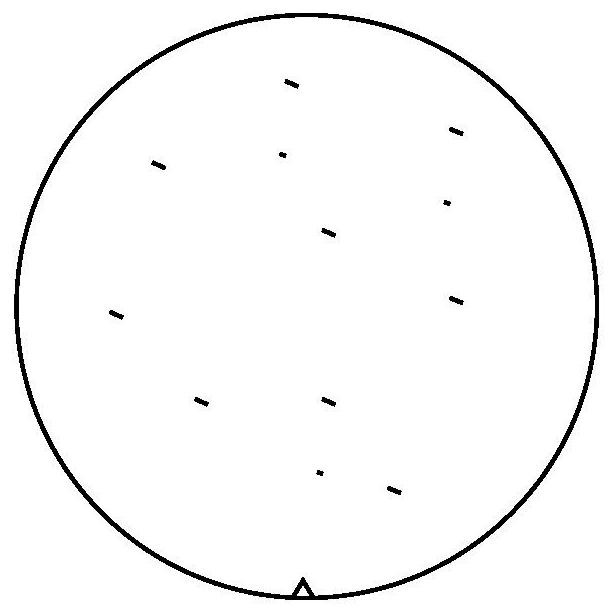

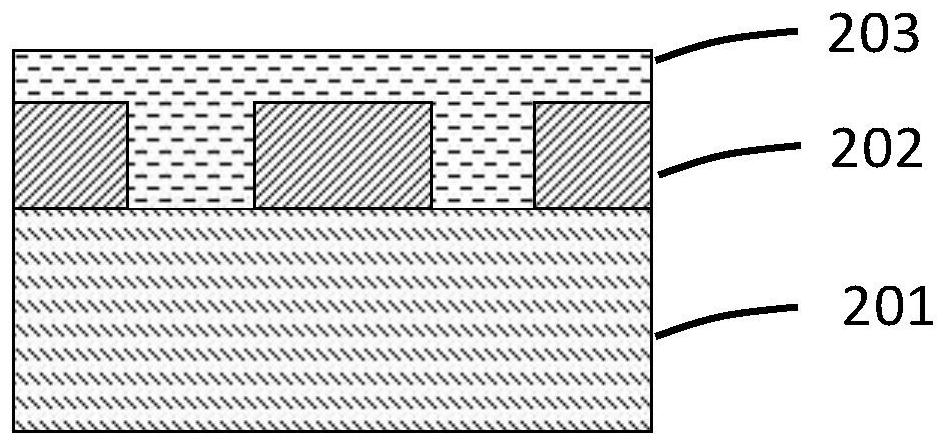

Control sheet and its manufacturing method and monitoring method of chemical mechanical polishing defects

ActiveCN109166812BEffective monitoringIncrease contrastSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The present invention provides a control chip, its manufacturing method and the monitoring method of chemical mechanical polishing defects, by forming a patterned first dielectric layer on the upper surface of the substrate, and at least filling the patterned first dielectric layer The second dielectric layer of the grooves to fabricate the control sheet. placing the control sheet on a chemical mechanical grinder and grinding it to remove the first medium layer; then, scanning the surface of the control sheet after the treatment to obtain the upper surface of the control sheet defects, so as to realize the monitoring of the chemical mechanical polishing defects. The control sheet provided by the present invention improves the contrast between the defects on the surface of the control sheet and the background, thereby improving the capture rate of the defects caused by chemical mechanical grinding by the optical scanning machine, and realizing the effective monitoring of the chemical mechanical grinding defects .

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Traction-driven mulch recycling machine

The invention discloses a traction drive type mulching film recycling machine. The traction drive type mulching film recycling machine comprises a machine frame and a film grabbing mechanism. The machine frame is provided with a car floor beam, a car top beam and a traction end connector. A film grabbing roller is arranged on the car floor beam through a bearing, a film connecting roller is installed on the car top beam through a bearing, film grabbing teeth are arranged on the outer surface of the film grabbing roller, film connecting teeth are arranged on the film connecting roller, and the film connecting teeth and the film connecting teeth are arranged in a straggled mode. A rotary shaft of a land wheel is provided with a first driving wheel and a second driving wheel which drive the film grabbing roller and the film connecting roller to rotate respectively. The number of the film grabbing times is increased, and the mulching film recycling machine is used for improving the film grabbing rate. A speed difference exists between the film grabbing roller and the film connecting roller, so that multiple coincidence chances exist between the film grabbing teeth and the film connecting teeth, and the film connecting success rate is increased. Upward oblique or bent film connecting transition plate avoiding grooves can go deep between the film connecting teeth, and film residues between the film connecting teeth are shoveled out and then slide down to a film discharging channel.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

A method for detecting insufficient etching of through holes

ActiveCN104078379BIncrease the number of viasImprove crawl rateSemiconductor/solid-state device testing/measurementEtchingTransmission gate

The invention discloses a detection method for under-etching of through holes. The method comprises the following steps: a plurality of test modules are built on the substrate of a semiconductor, each test module simulates an SRAM device structure and comprises two simulation transmission gate transistors, two simulation pull-up transistors and two simulation pull-down transistors; the simulation transmission gate transistors, the simulation pull-up transistors and the simulation pull-down transistors are NMOS devices in a P trap, and a grid electrode is not formed in the active area of each simulation transmission gate transistor; a plurality of contact holes filled with metal are formed in each test module; the contact holes are connected with the position, corresponding to the grid electrode, of the active area of each simulation transmission gate transistor at least; metal interconnecting wires and conductive through holes are formed in the contact holes; test modules are scanned under the positive potential condition by an electron beam defect scanner, and the defect of under-etching of through holes of the test modules is detected according to image characteristic patterns obtained through scanning. The method provided by the invention can increase the capturing rate of the defect of under-etching.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

A car cylinder head feeding and reclaiming device

InactiveCN108974917BRealize automatic feeding processNo manual operationConveyor partsCylinder headMachine building

The invention discloses an automobile cylinder cover feeding and discharging device and belongs to the field of machine manufacturing. The automobile cylinder cover feeding and discharging device comprises a mounting frame, a rodless air cylinder, a connecting rod and a conveying gripper, wherein the conveying gripper comprises a push rod and a discharging rod, the discharging rod is arranged at the top of a mounting plate, and the push rod is arranged under the mounting plate. The automobile cylinder cover feeding and discharging device can be matched with an assembly line to achieve automatic feeding and discharging, save manual operation and achieve high safety.

Owner:北京宏远鑫瑞科技有限公司

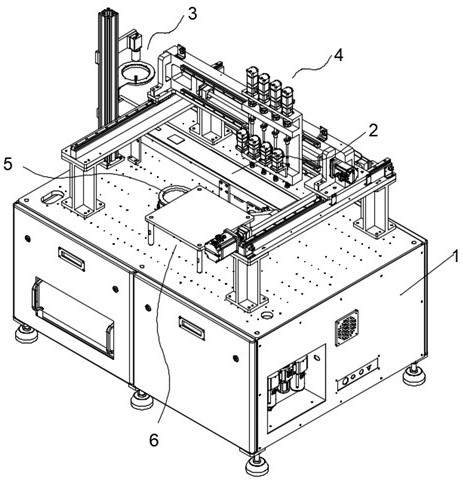

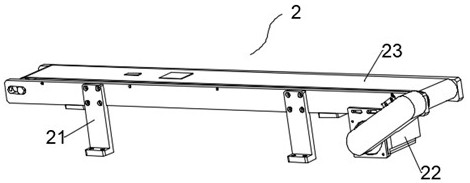

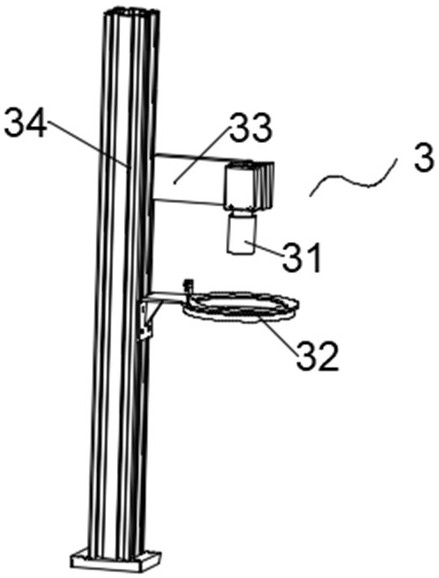

Visual guidance grabbing equipment with four-axis platform

PendingCN114701853AImprove crawl rateReduce biasConveyorsConveyor partsControl engineeringMechanical engineering

The invention is suitable for the field of grabbing equipment, and provides four-axis platform visual guidance grabbing equipment which comprises an equipment rack and further comprises a belt conveying mechanism fixedly connected with a main body rack; the visual guiding mechanism is fixedly connected with the four-axis material taking mechanism, and the visual guiding mechanism carries out coordinate positioning and visual guiding on the product in a shooting mode; the four-axis material taking mechanism is fixedly connected with the main body rack, and the four-axis material taking mechanism can drive the product to move in the horizontal plane while sucking and positioning the product; the angle compensation mechanism is fixedly connected with the main body rack, and in the process that the four-axis material taking mechanism grabs the product, the angle compensation mechanism can photograph the product and transmit photographing coordinates to the four-axis material taking mechanism; according to the four-axis platform visual guidance grabbing equipment, the most advanced visual guidance scheme is adopted, the grabbing speed is high, and deviation is small.

Owner:ZHIHUIXUANTIAN INTELLIGENT SYST (HANGZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com