Vertical chip capacitor and manufacturing process thereof

A chip capacitor and manufacturing process technology, applied in the field of microelectronics, can solve the problems of sacrificing the integrity of the frame, worrying about the efficiency and accuracy of the chip, and the application of capacitors in the package components, so as to save the investment of equipment and manpower, improve Internal structure, the effect of improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

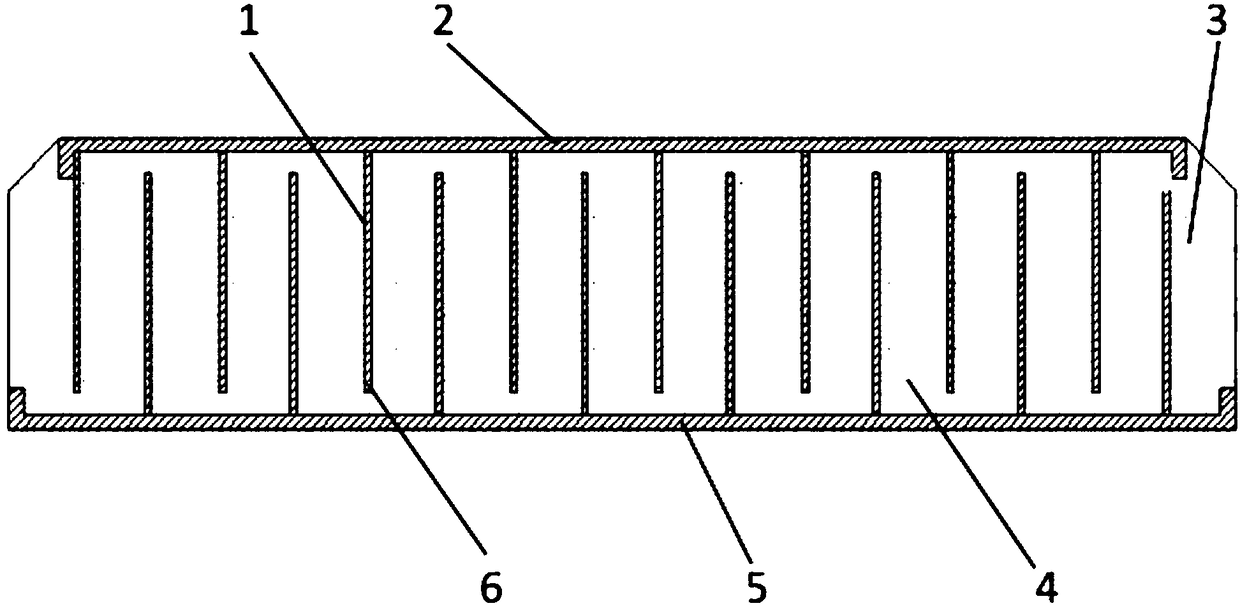

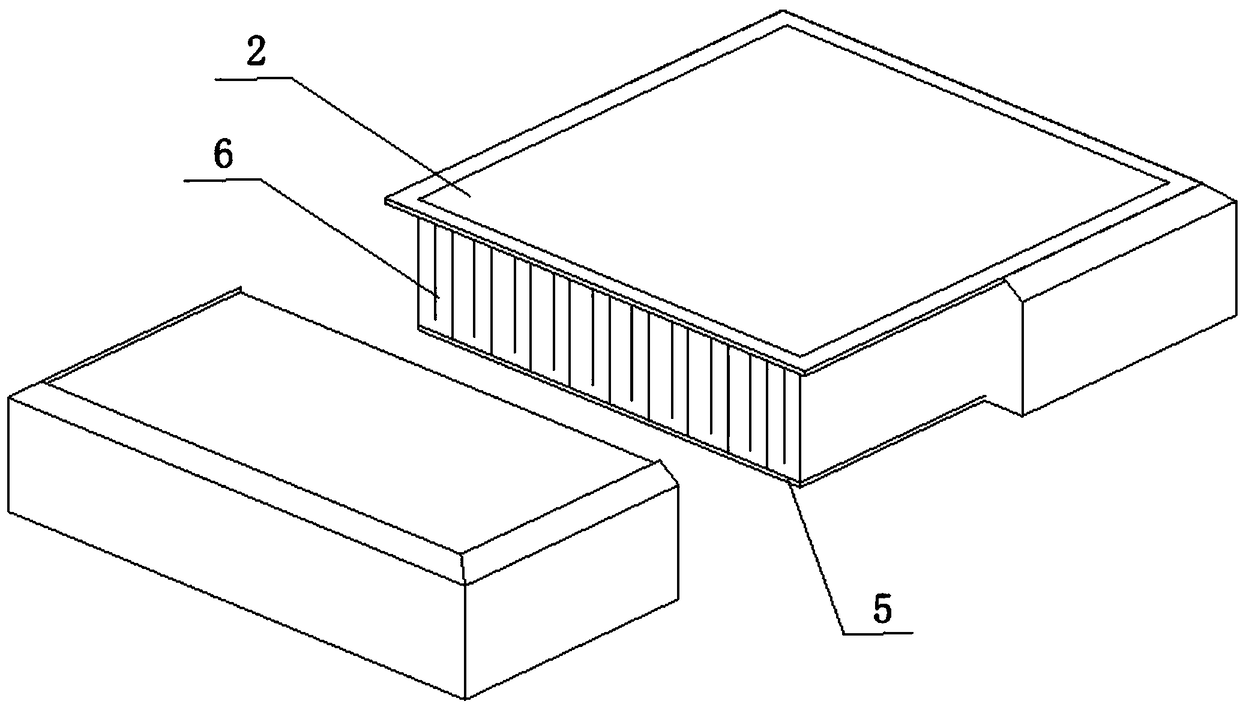

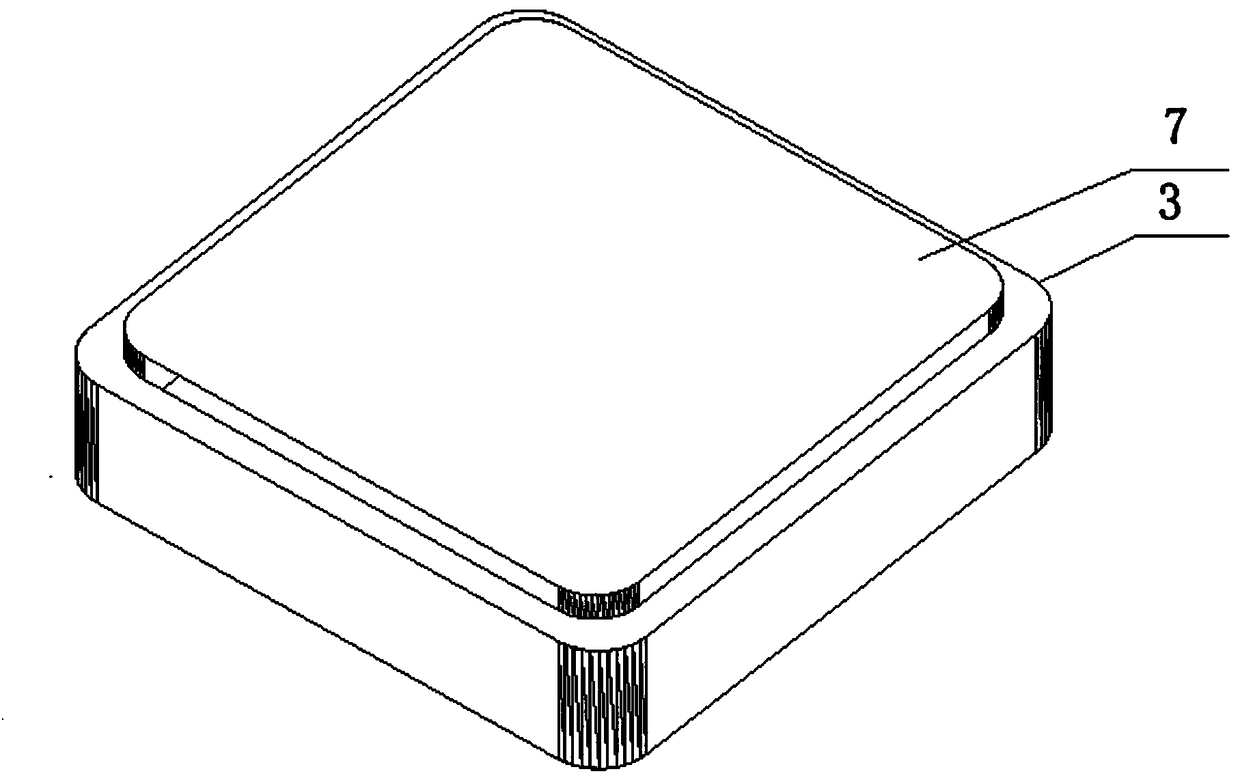

[0050] Such as Figure 1-3 As shown, the vertical chip capacitor of the present invention includes a capacitor base 3, and the capacitor base 3 includes an upper end face 2 and a lower end face 5, and internal electrodes 6 are provided on the inner sides of the upper end face 2 and the lower end face 5, and the inner electrodes 6 Including the upper electrode and the lower electrode, the upper electrode and the lower electrode are vertically staggered, and one end of the upper electrode is connected to the upper end surface 2, and the other end is not in contact with the lower end surface 5, and the lower electrode is connected to the lower end surface 5, and the other end is not in contact with the upper end surface 2, A metal layer is provided outside the upper end surface 2 and the lower end surface 5 to form an external terminal electrode 7 , which is parallel to the installation surface and connected to the internal electrode 6 .

[0051] To further illustrate the above-m...

Embodiment 2

[0060] Such as Figure 9 As shown, the silicon material is taken as the optimal embodiment, and the construction principle is that the metals of the upper and lower internal electrodes 6 are separated by electronic silicon to store and release electric energy in the form of static electricity. Its capacity formula is as follows:

[0061]

[0062] Where C: Capacitance; ε: Dielectric constant of the insulator between electrodes; K: Dielectric constant (depending on the 4 types of dielectric layers)

[0063] A: conductive area; D: thickness of dielectric layer 4 (thickness of thin strip); n: number of slots (number of stacked layers);

[0064] Capacity adjustment method:

[0065] 1) Under the condition that the external dimensions of the capacitor remain unchanged, the capacity is adjusted by increasing or decreasing the number of internal electrode 6 slots, or adjusting the thickness of the dielectric layer 4 .

[0066] 2) Under the condition that the plane size of the cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com