Detection method for under-etching of through holes

A technology of through-hole etching and detection methods, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as difficult online process window optimization and provide effective reference, and achieve semiconductor online manufacturing and yield Improve security, improve monitoring sensitivity, and improve the effect of crawling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] figure 1 A schematic flow chart of the method for detecting insufficient etching of via holes provided in this embodiment. Such as figure 1 As shown, the detection method includes steps:

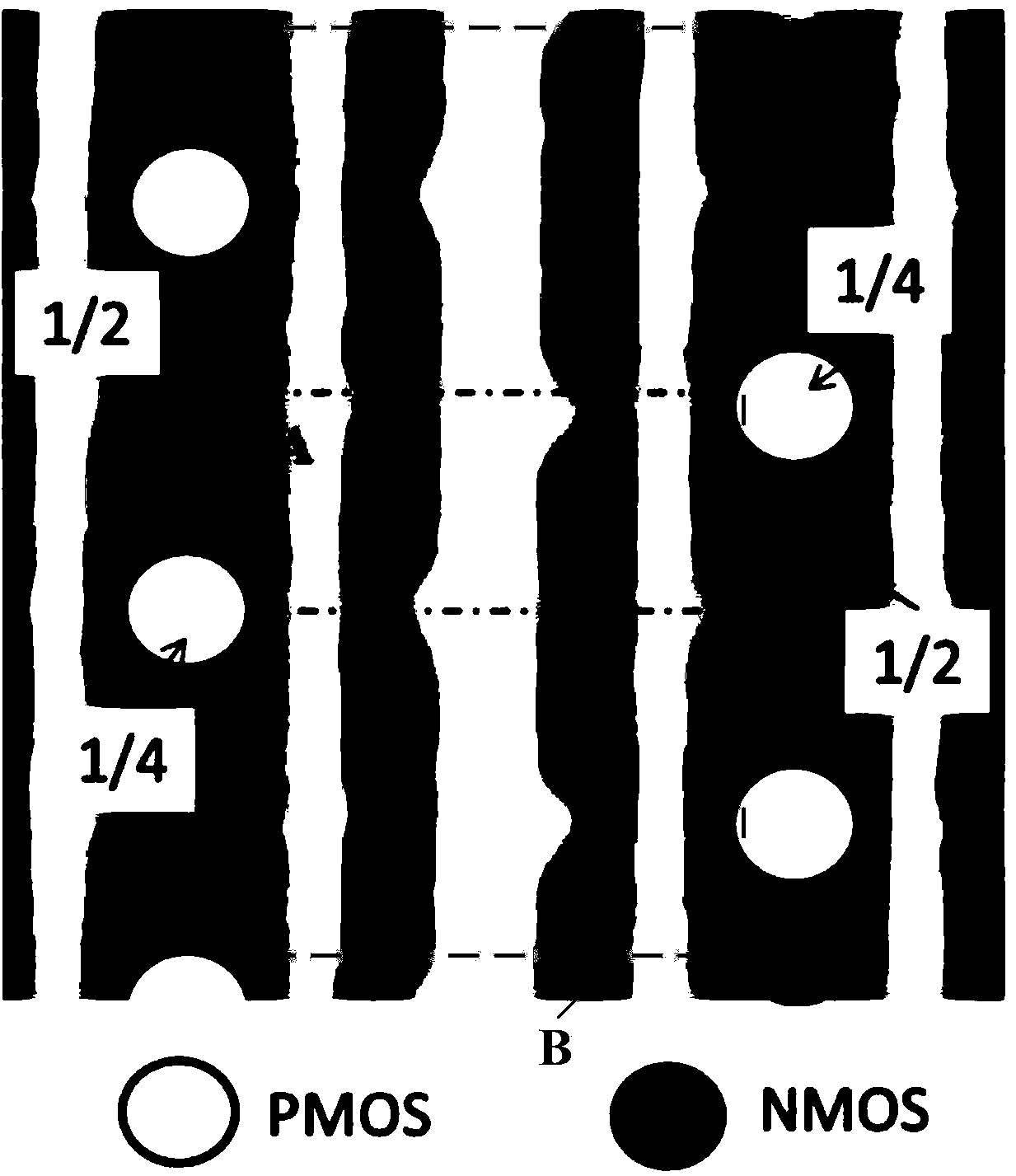

[0040] Step S1: Build a plurality of test modules on the semiconductor substrate, each test module simulates the SRAM device structure, wherein each transistor of the test module is an NMOS device in a P well, and the active region of the simulated transmission gate transistor is not formed grid.

[0041] Specifically, since each test module simulates a SRAM device structure, each test module includes two analog pass-gate transistors, two pull-up transistors and two pull-down transistors. Unlike the SRAM device structure, the test modules These transistors are all NMOS devices in the P-well. In addition, another difference of the present invention is that the analog pass-gate transistor only has an active area without forming a gate on the active area.

[0042] The formation meth...

Embodiment 2

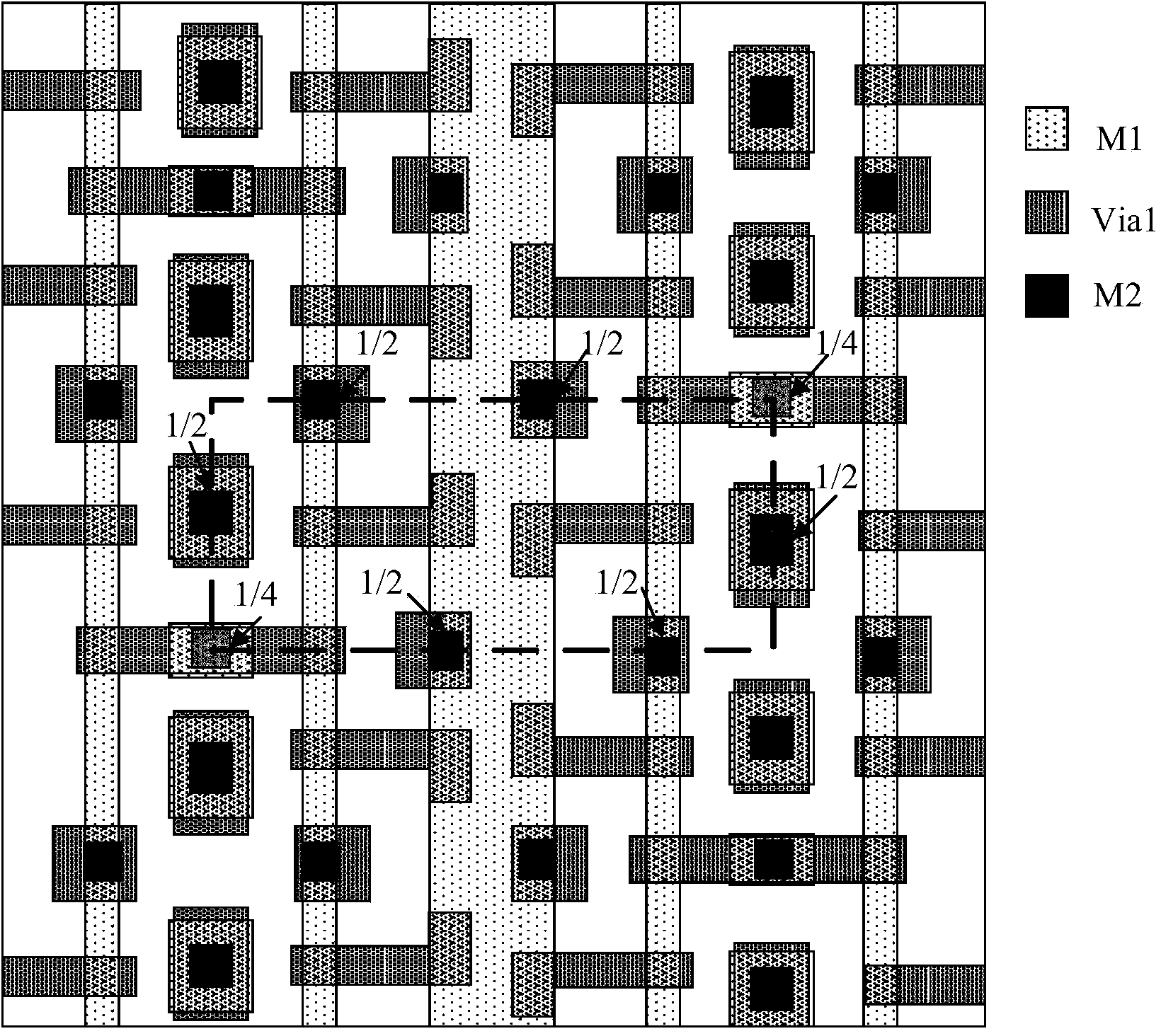

[0053] Although the above-mentioned embodiment can increase the detection via hole ( Figure 2b In the case of etching at A), but for multiple vias connected by the same metal interconnection line, such as Figure 2b In the B area, if some of the through holes are under-etched, it will still not be detected. Therefore, in order to further increase the number of detectable vias, this embodiment improves the method for forming vias and metal interconnection lines.

[0054] Please refer to Figure 5a to Figure 5g , which is a schematic diagram of each step of the method for forming conductive vias and metal interconnections in this embodiment. In this embodiment, the steps of establishing test modules, forming a plurality of contact holes on each test module and filling metal are the same as those in the first embodiment, and will not be repeated here.

[0055] Please refer to Figure 5a and Figure 5b After the contact hole is formed, filled with metal and planarized, a die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com