Molding technology for crankshaft forged piece flanges capable of being accurately grabbed by robot

A robot and flash technology, which is applied in the field of crankshaft forging and forming, can solve the problem that the robot cannot accurately grasp the flash, and achieve the effects of high accurate grasping rate, improved production efficiency, and stable flash forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] A flash forming process for crankshaft forgings that can be adapted to accurate grasping by robots, comprising the following steps:

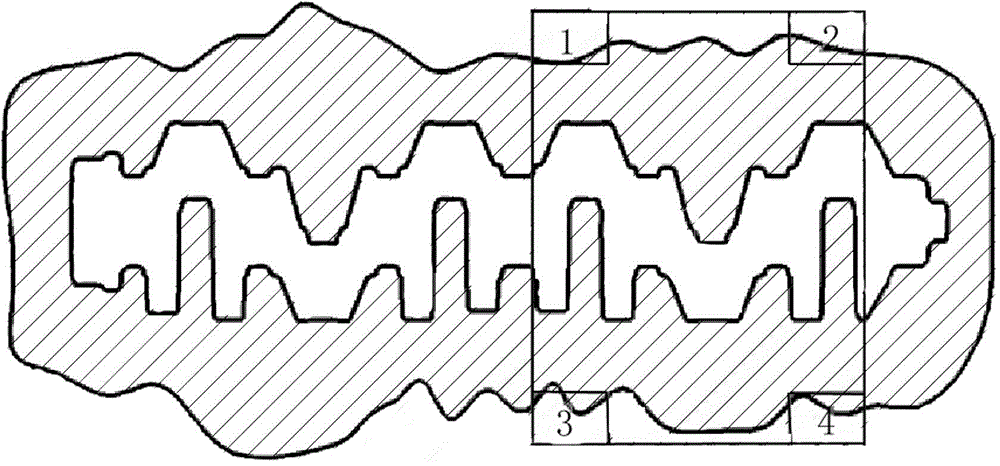

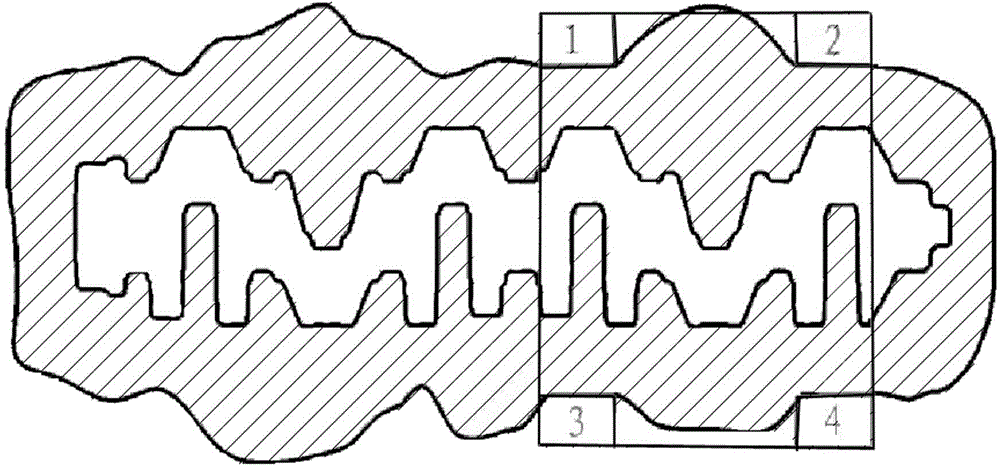

[0017] 1) Design the flash positioning platform: use CAE technology, use FORGE software to simulate and analyze the shape of the flash, so as to determine the size of the flash, and then design the flash positioning platform; among them, in order to prevent the flash formed by pre-forging and final forging There is interference in the flash positioning table, and the horizontal and radial dimensions of the pre-forging positioning table are increased by 5mm compared with the final forging positioning table;

[0018] 2) Processing flash positioning table: according to the designed flash positioning table style, the pre-forging lower die and the final forging lower die's flash grabbing position are surfacing welded, and then the positioning table is processed by the machining center, and at the same time Make a positioning platform avoidance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com