Control sheet and its manufacturing method and monitoring method of chemical mechanical polishing defects

A chemical-mechanical and defect technology, used in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc. Contrast, improve the effect of crawl rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

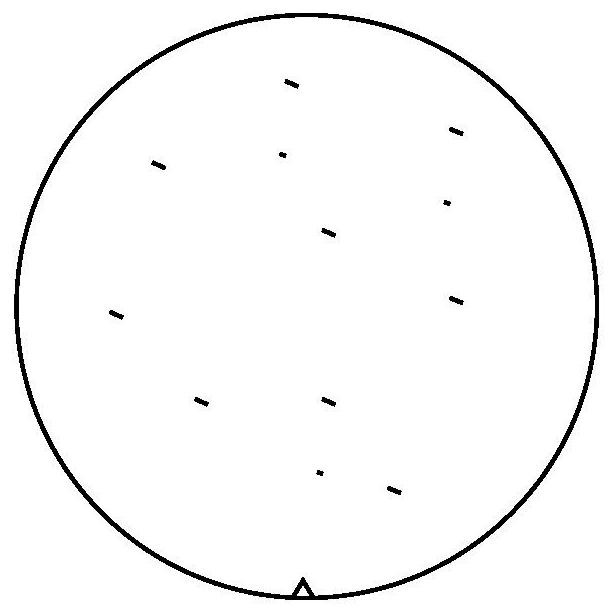

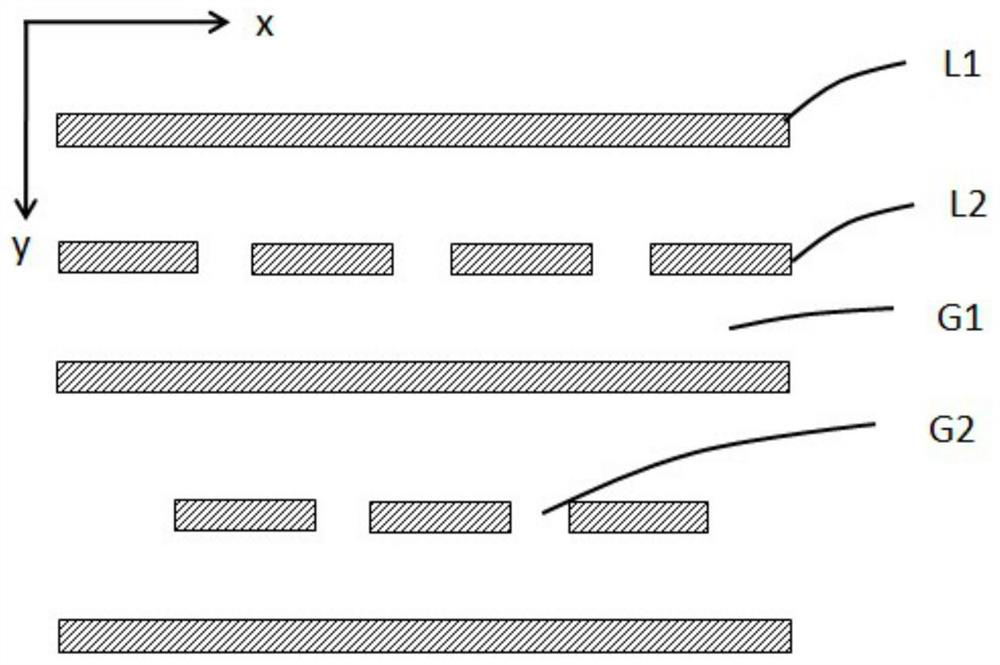

[0045] In order to make the purpose, advantages and characteristics of the present invention clearer, the following in conjunction with the attached Figure 1-7The control sheet proposed by the present invention, its manufacturing method and the monitoring method of chemical mechanical polishing defects are further described in detail. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

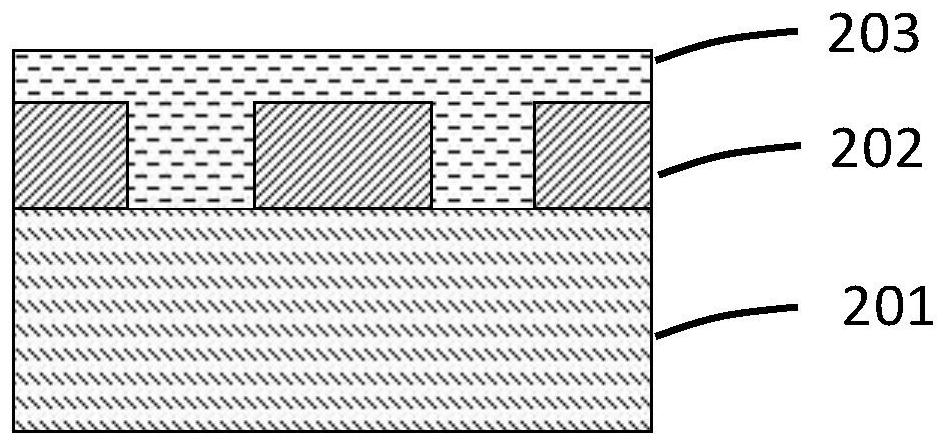

[0046] An embodiment of the present invention provides a control sheet, refer to Figure 2a , Figure 2a It is a schematic longitudinal cross-sectional view of a control sheet according to an embodiment of the present invention, and the control sheet includes: a substrate 201 , a patterned first dielectric layer 202 and a second dielectric layer 203 . Wherein, the patterned first dielectric layer 202 is formed on the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com