Cylindrical permanent-magnet linear motor with modular C-shaped stator cores

A permanent magnet linear motor and stator core technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increased motor length, unsuitable volume restrictions, etc., to achieve reduced positioning force, small volume, enhanced reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

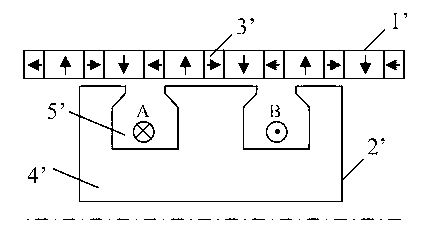

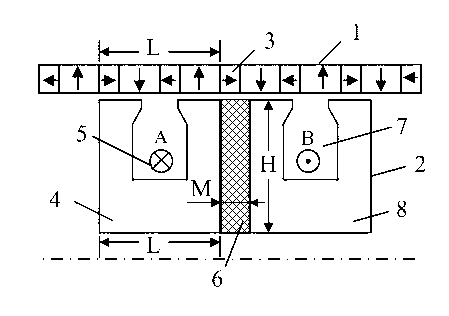

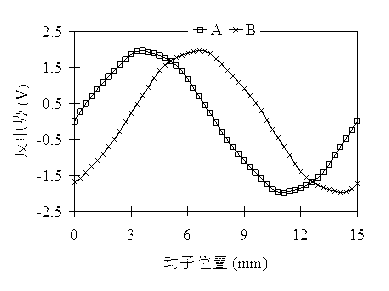

[0024] see figure 2 , the present invention includes an outer rotor ring 1 and an inner stator ring 2, the outer rotor ring 1 is composed of a Halbach array permanent magnet ring 3, and an axially magnetized permanent magnet is sandwiched between two permanent magnets with opposite radial magnetization directions , and the magnetization direction of two adjacent axially magnetized permanent magnets is also opposite. The axial width of the radially magnetized permanent magnet is twice the axial width of the axially magnetized permanent magnet.

[0025] The inner stator ring 2 is composed of a first C-shaped iron core 4 , a second C-shaped iron core 8 , an armature winding 5 and a magnetic barrier 6 . Both the first C-shaped iron core 4 and the second C-shaped iron core 8 are made of magnetically permeable materials, which can be formed by laminating punched sheets, and the magnetic barrier 6 is made of non-magnetically permeable materials.

[0026] The first C-shaped iron co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com