Ballast flocculation and sedimentation water treatment system with simplified sludge recirculation, and process therefor

A technology for sludge return and water treatment equipment, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, sludge treatment, etc., and can solve problems such as expensive, impractical, and material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

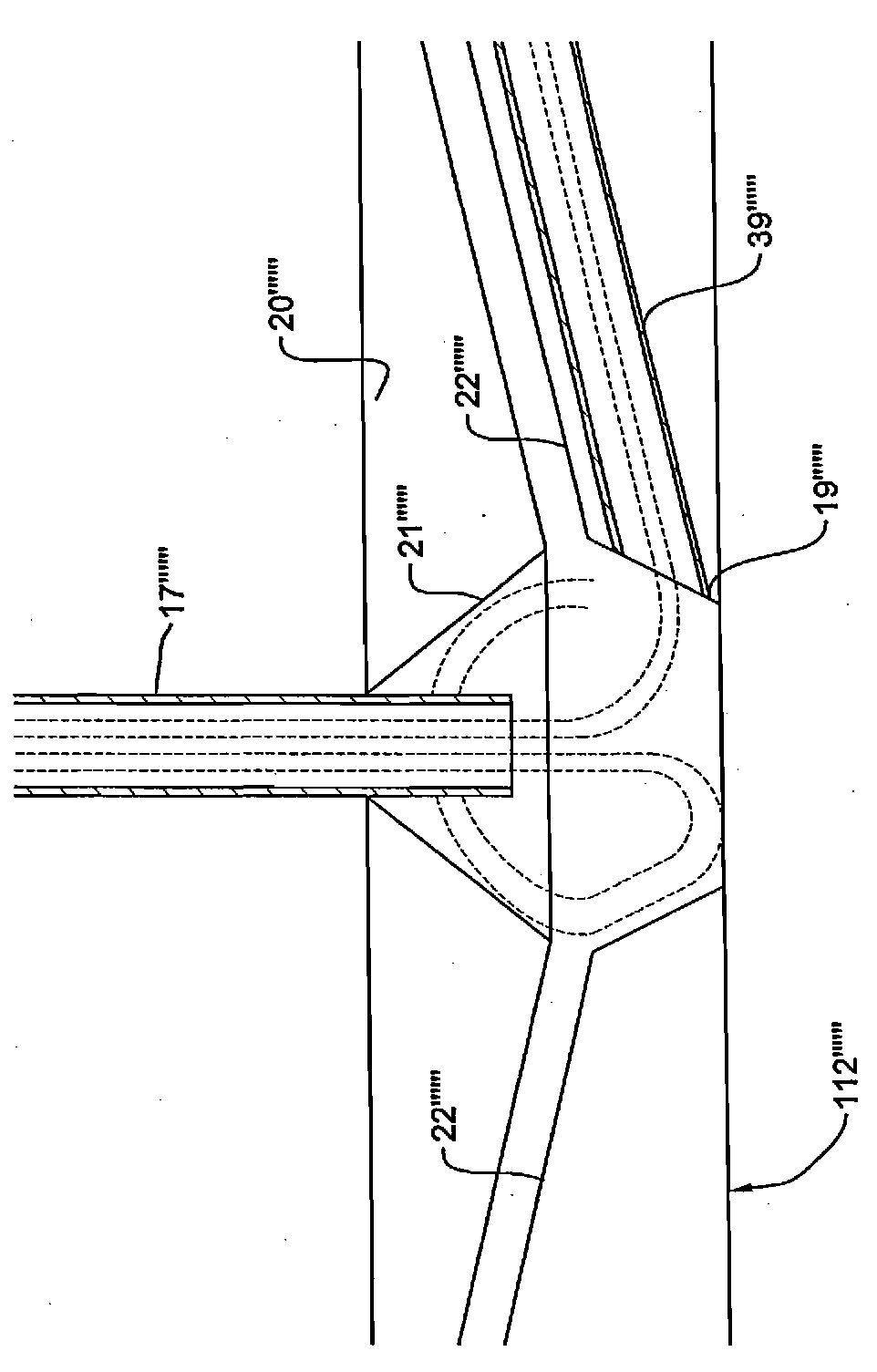

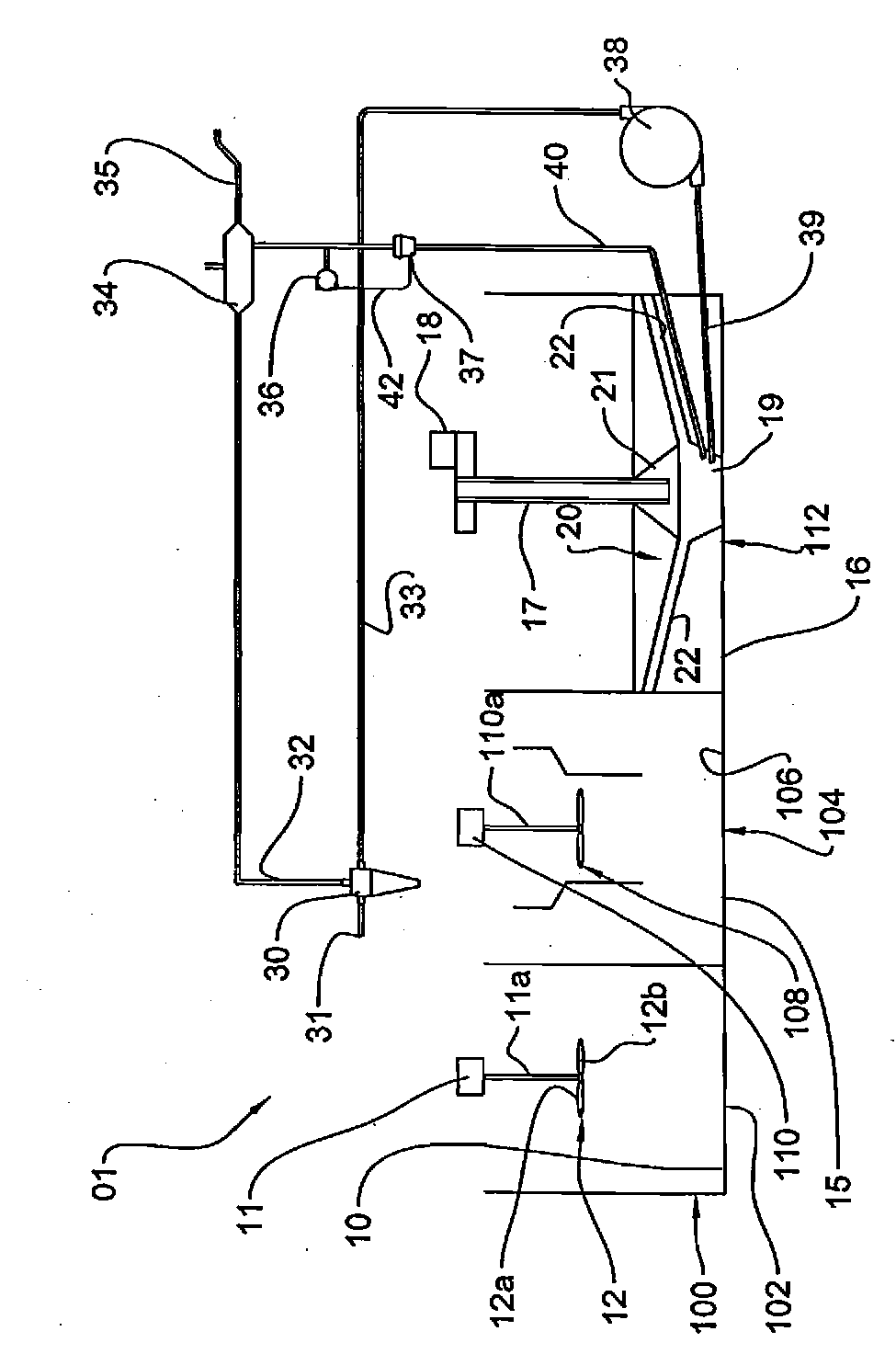

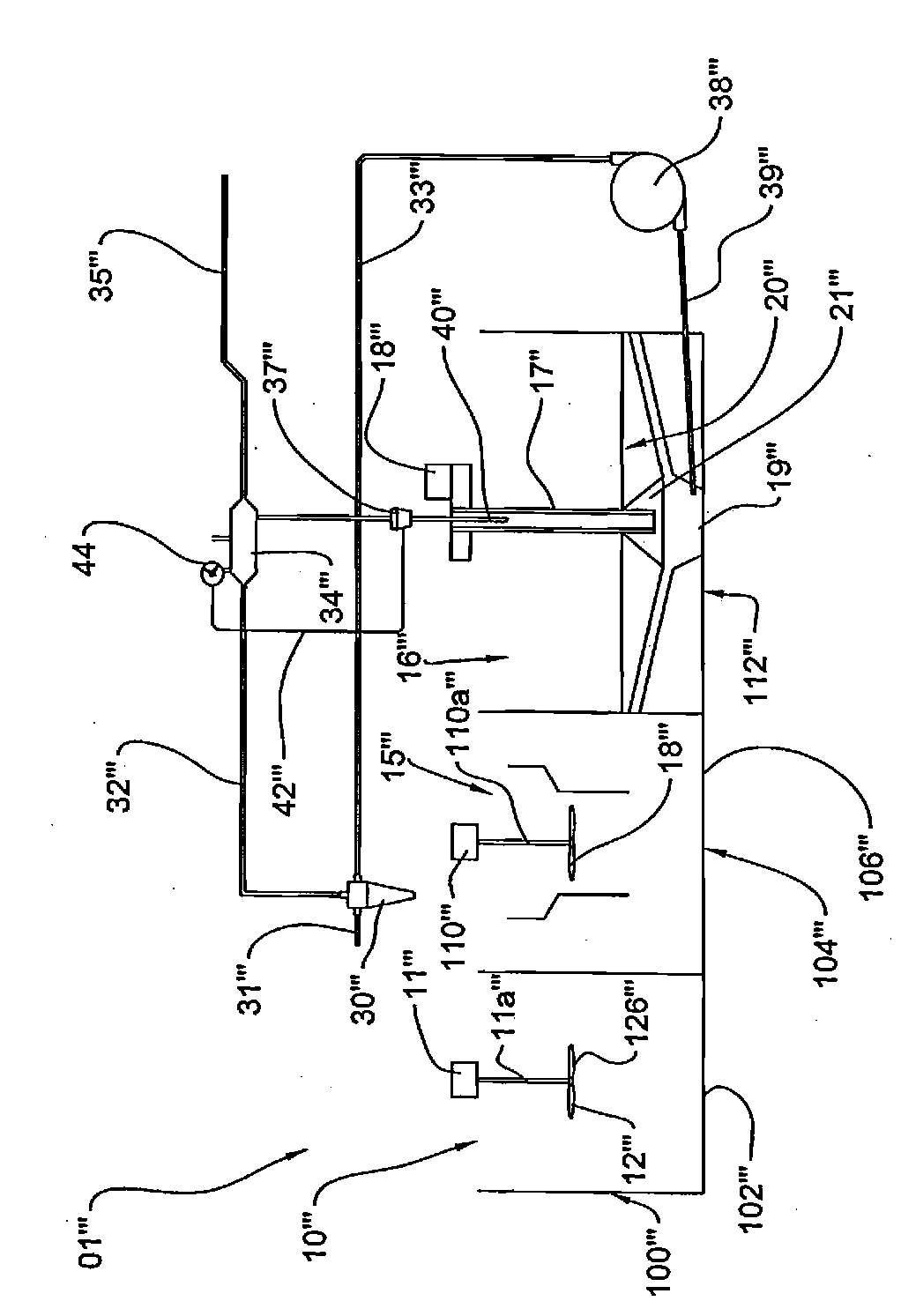

[0087]Fig. 1 generally shows a water treatment plant 01 with an added sludge return system corresponding to Embodiment 1 of the present invention, which includes three main areas in which water circulates. Water flows from left to right for progressive purification of water from its pollutants. The upstream condensation zone 10 is defined as receiving water by means of a pipe, for example a cuboid-shaped upright container 100, which may be a conventional pipe and is not shown in the figure. A coagulant, preferably a trivalent metal salt, is added to the water flowing in the coagulation zone 10 in order to initiate the formation of aggregates of contaminants in the water. Small pollutant particles suspended in this water are generally negatively charged, and are thus attracted to the trivalent metal salt, which dissolves in the water, leaving three positively charged ions. The rotation of the mixer 12 is allowed by a motor 11 fixed above the coagulation zone, the motor 11 bein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com