Electromagnetic valve casing pipe component assembly tooling

A technology for assembly tooling and solenoid valves, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of complex assembly process, low efficiency, and many stations, so as to improve assembly efficiency, save assembly time, and realize large-scale The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

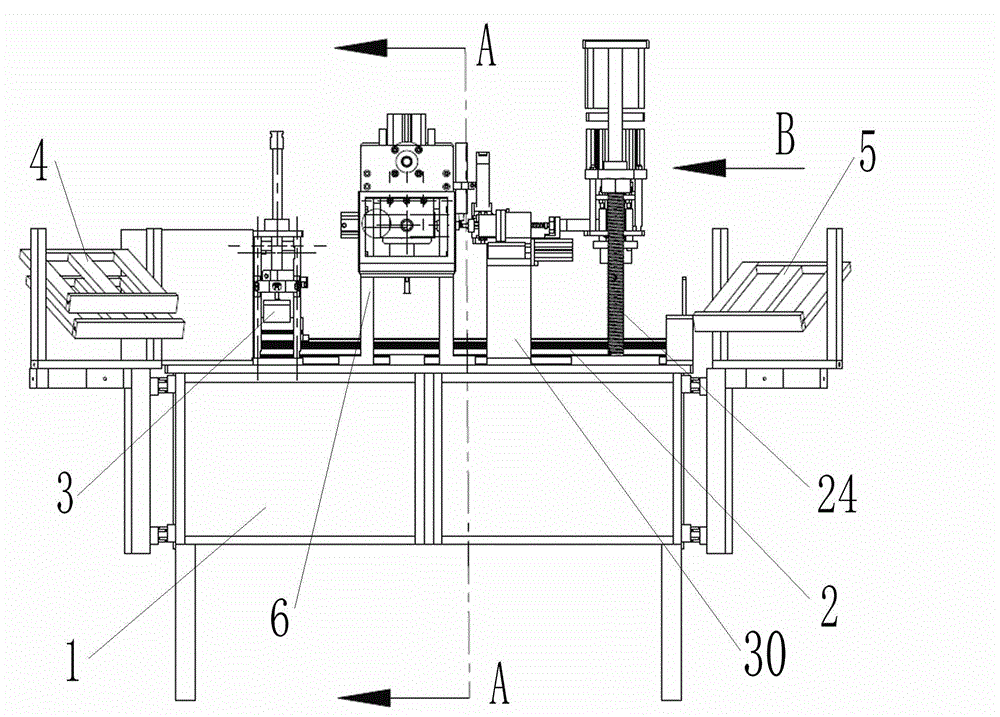

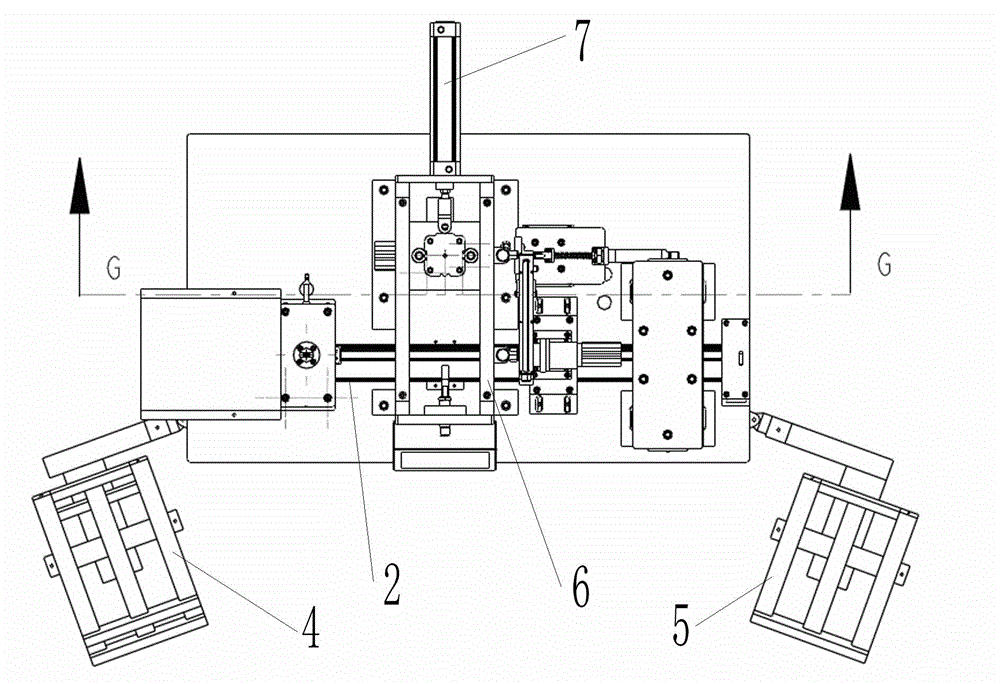

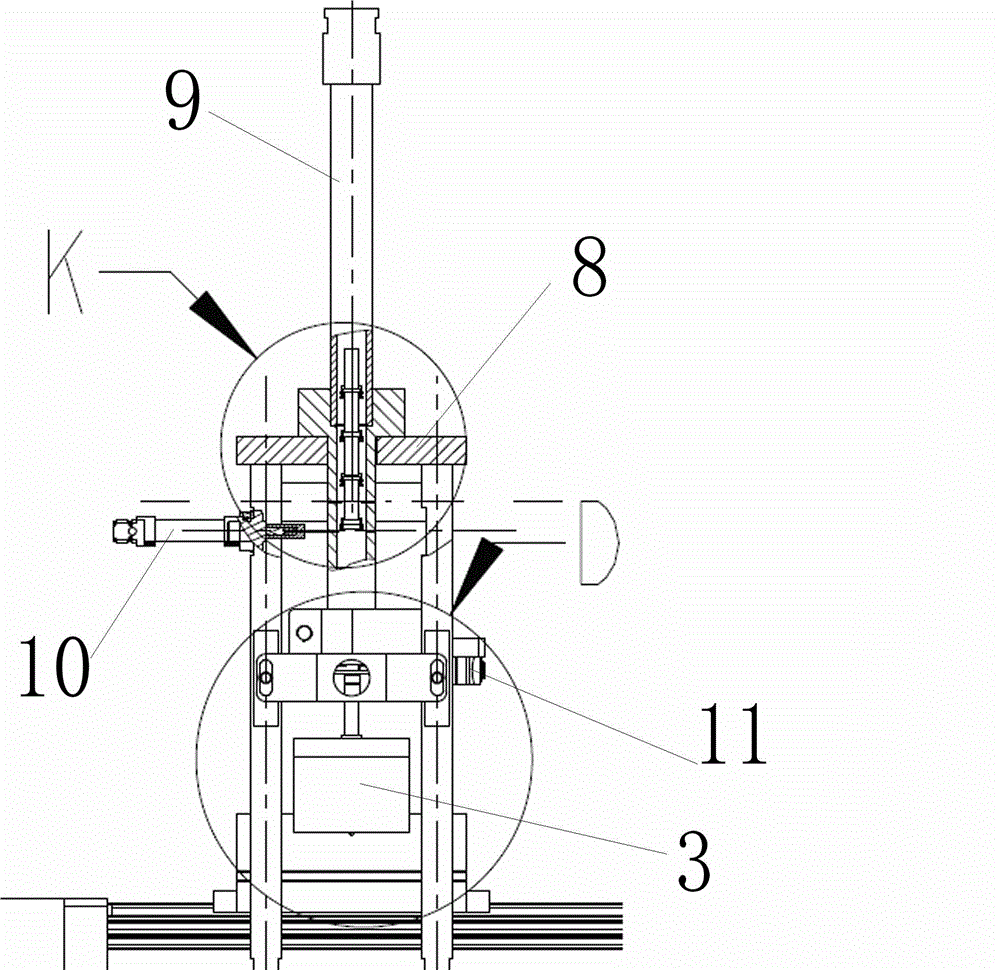

[0031] Attached below figure 1 to attach Figure 15 The present invention will be further described.

[0032] as attached figure 1 , attached figure 2shown. The assembly tooling of the solenoid valve casing assembly includes a workbench 1, a casing blanking device sequentially arranged on the workbench 1, a static iron core feeding device, a static iron core glue coating device, and a static iron core 55 from the static iron The static iron core conveying device for the core feeding device to the static iron core gluing device, the static iron core pressing device for pressing the glued static iron core 55 into the casing 14, and the casing assembly riveting The device also includes a linear unit 2 installed on the workbench and a positioning block 3 installed on the linear unit 2 for fixing the casing 14 dropped by the casing blanking device. The positioning block 3 is driven by the linear unit 2 The bottom can move to the corresponding positions of the casing blanking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com