Automatic cooked sweet potato slicing device

A slicing device and sweet potato technology, applied in metal processing and other directions, can solve the problems of heavy workload, low production efficiency, inability to ensure uniform slice thickness and personal safety, etc., and achieve the effect of uniform slicing and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

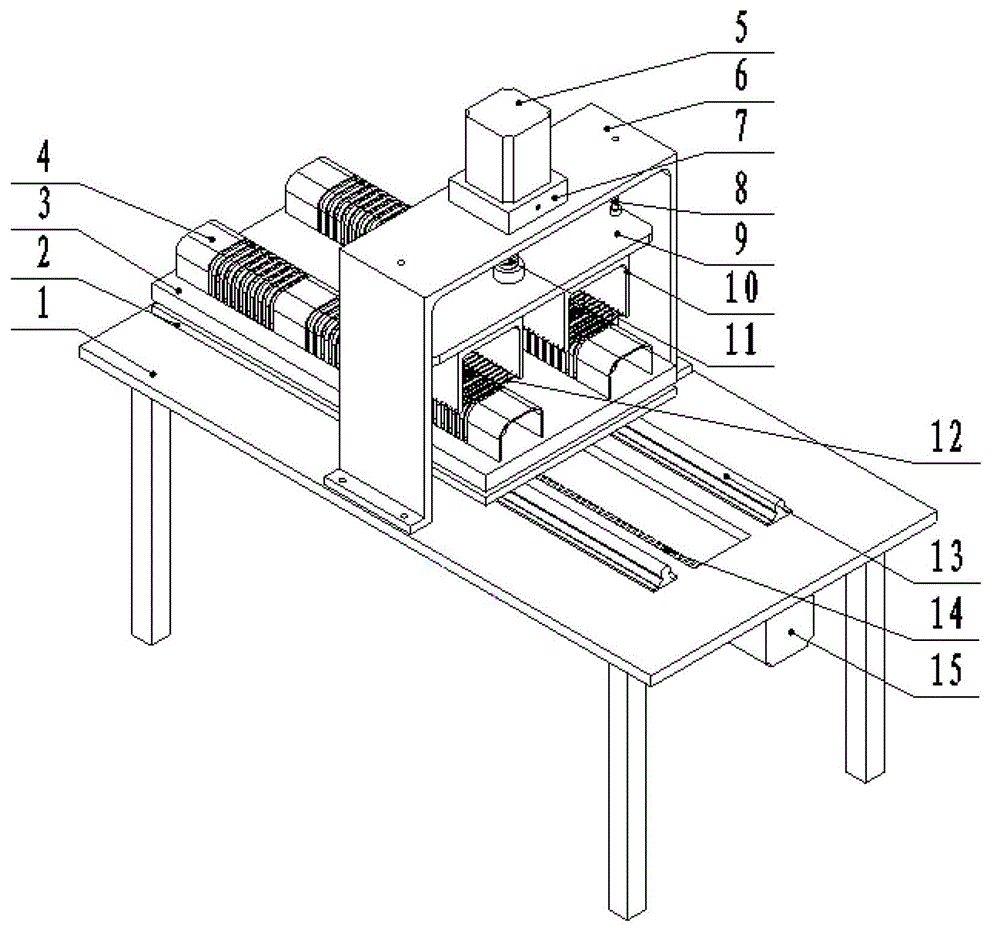

[0008] An automatic slicing device for cooked sweet potatoes, which is composed of a workbench 1, a slide plate 2, a sweet potato clamp 3, a sweet potato clamp cover 4, a slice motor 5, a support frame 6, a reducer 7, a guide rod 8, a cutter frame connecting rod 9, a cutting Tool rest 10, vertical lead screw 11, thin iron wire 12, slide guide rail 13, horizontal lead screw 14, slide plate motor 15 are formed, and it is characterized in that: workbench 1 is placed on the ground, slide plate guide rail 13 is installed on the workbench 1, The skateboard 2 is installed on the skateboard guide rail 13, the skateboard motor 15 is fixed on the workbench 1, the skateboard motor 15 and the horizontal screw 14 are connected together, the horizontal screw 14 is installed on the skateboard 2, and the sweet potato clamp 3 is fixed on the skateboard 2, The sweet potato clamp cover 4 is installed on the sweet potato clamp 3, the support frame 6 is installed on the workbench 1, the slicing mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com