Diode silicon stack cutting process and special tool thereof

A cutting process and diode technology, applied in the direction of fine working devices, working accessories, manufacturing tools, etc., can solve the problems of processing efficiency, easy to fall flat, and unable to cut smoothly, so as to shorten the cutting cycle, improve product quality, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

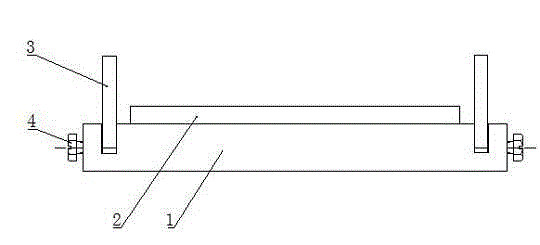

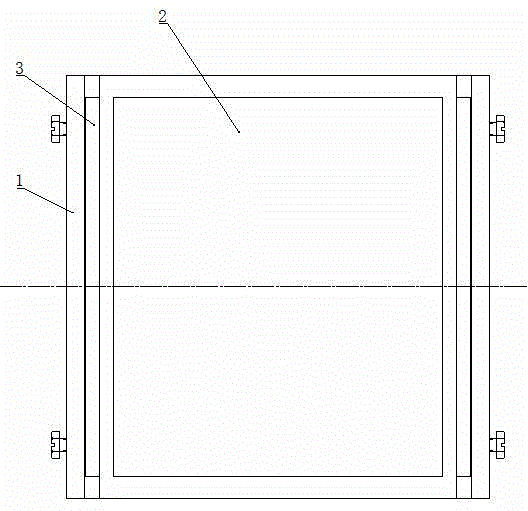

[0017] In the present invention, the silicon stacking tool is a conventional process fixture for the production of silicon grains in diode manufacturing enterprises, such as figure 1 , 2 As shown, it includes an aluminum mold base 1 , a glass bottom plate 2 , a glass baffle 3 and locking bolts 4 .

[0018] The aluminum mold base 1 is rectangular, and a glass bottom plate 2 is placed on its upper surface. The aluminum mold base 1 and the glass bottom plate 2 are connected by paraffin. There are through grooves on both sides of the aluminum mold base 1, and the lower end of the glass baffle 3 is embedded in the through groove. and locked and fixed by the locking bolt 4 on the side wall.

[0019] When cutting the diode silicon stack, the specific process is as follows:

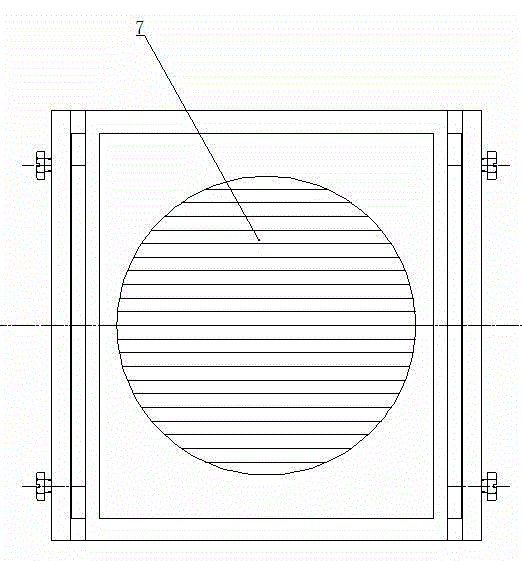

[0020] First, two layers of silicon stacks 7 are horizontally placed on the glass bottom plate 2 of the silicon stack bonding tool, and are fixed to the glass bottom plate 2 by paraffin to achieve one-time bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com