Totally-enclosed double-air cushion belt conveyor

A belt conveyor, fully enclosed technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of material loss, high cost, flying materials, etc., to achieve fewer parts to be processed, low equipment weight, The effect of large conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

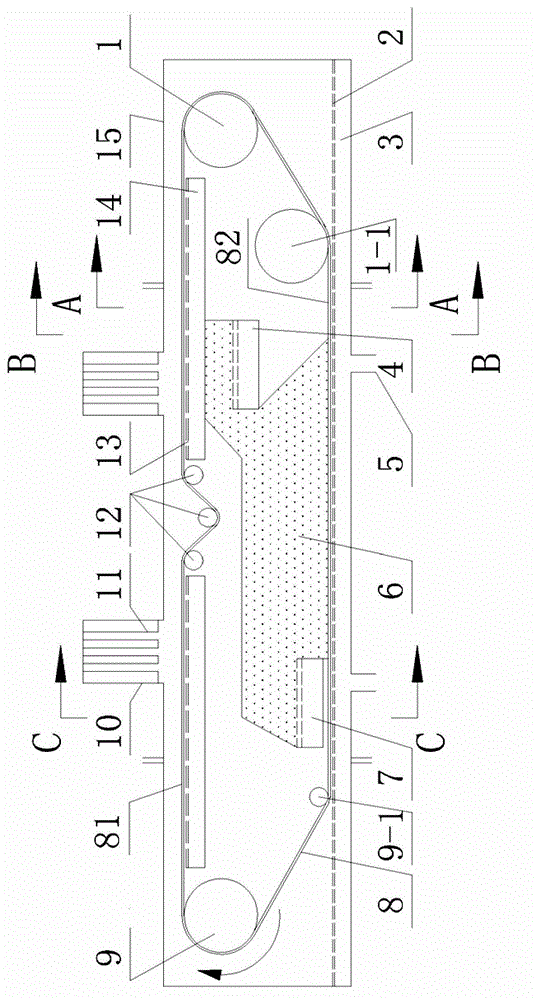

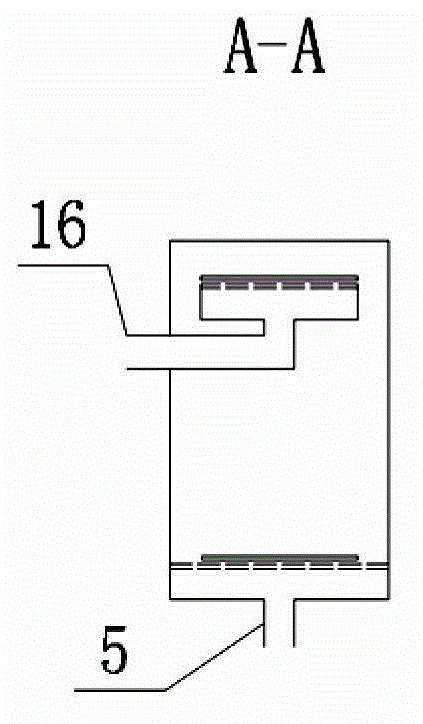

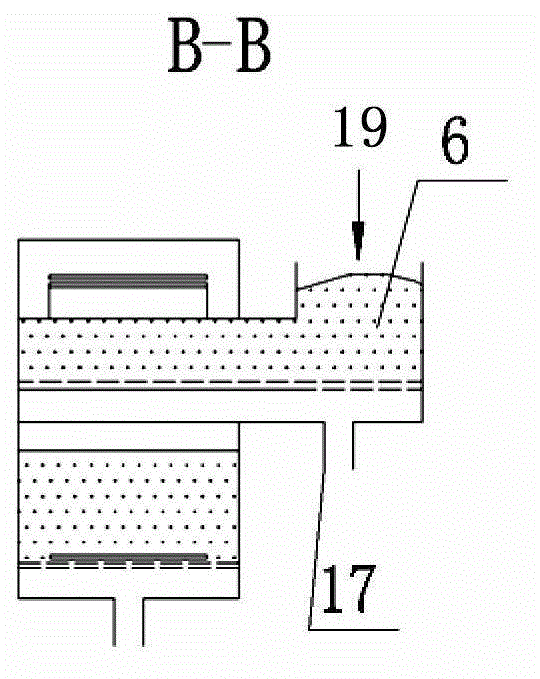

[0023] Now, will combine Figure 1 to Figure 4 Further description will be made on the fully enclosed double air cushion belt conveyor according to the exemplary embodiment of the present invention.

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the fully enclosed double-air-cushion belt conveyor according to an exemplary embodiment of the present invention is mainly composed of a front driven roller 1, a driven pressure roller 1-1, a lower air-cushion gas distribution plate 2, and a lower air-cushion gas distribution plate air cavity 3. Feeding system 4. Lower air cushion air supply system 5. Unloading system 7. Conveyor belt 8. Back-end drive roller 9. Drive pressure roller 9-1. Exhaust air filter system shell 10. Exhaust air filter system filter layer 11. Conveyor belt tensioning system 12, upper air cushion gas distribution plate 13, upper air cushion gas distribution plate air chamber 14, conveying system housing 15, upper air cushion air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com