Purifying method for volatile chemical organic matters

A purification method and volatile technology, which is applied in the field of purification of volatile chemical organic compounds, can solve the problems of poor sealing performance and low purity, and achieve the effects of preventing organic compounds from volatilizing, improving separation efficiency, and prolonging vapor residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

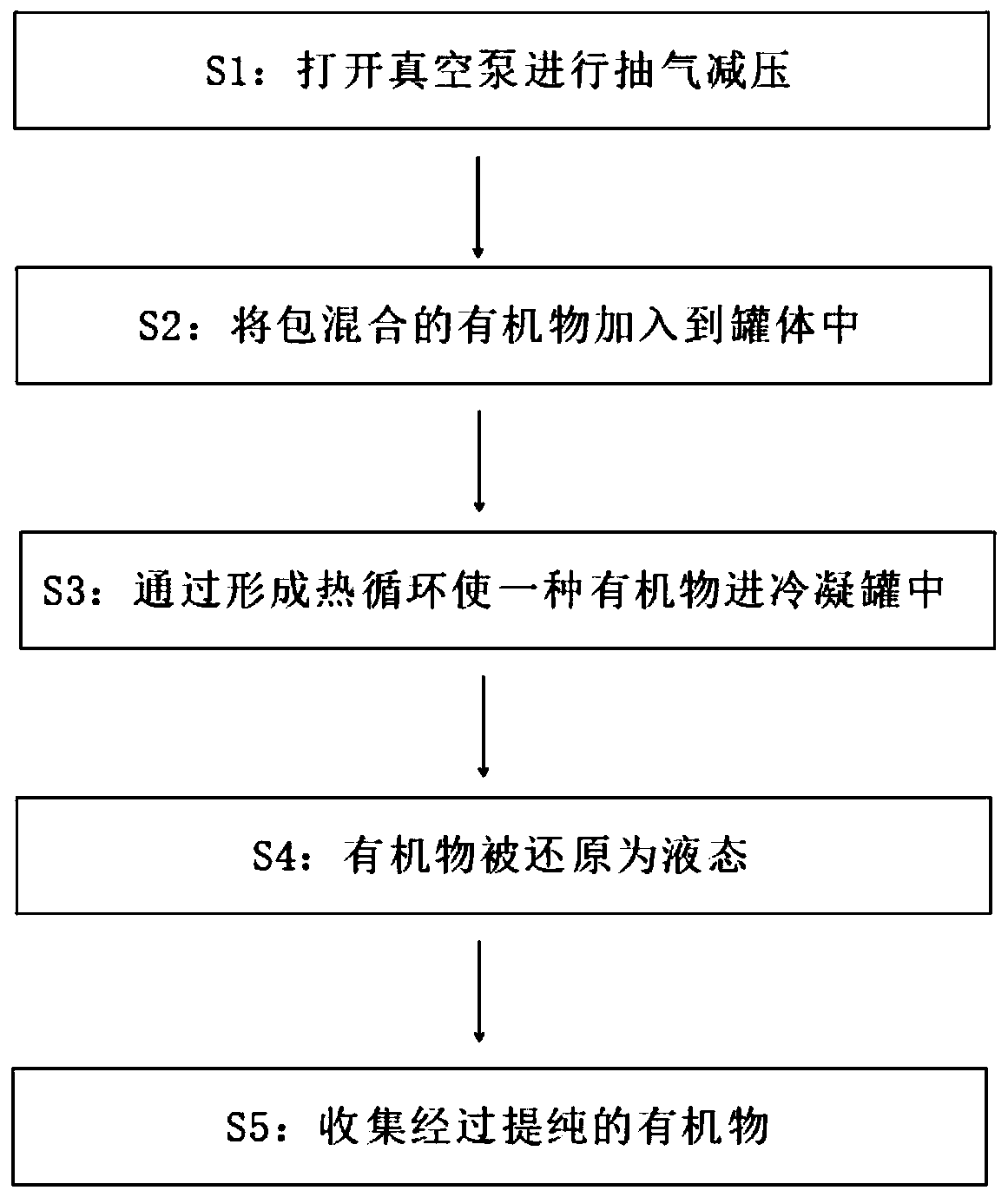

[0065] Such as figure 1 Shown, a kind of method for the purification device of volatile chemical organic compound comprises the following steps:

[0066] S1: Turn on the vacuum pump 23 for pumping and reducing pressure to ensure that the tank is in a vacuum state;

[0067] S2: Turn off the vacuum pump 23, add chemical substances including two kinds of volatile organic compounds into the tank body provided with the stirring mechanism 10 and communicated with the condensation tank 14 through the feed port 12, and seal the feed port 12 through the sealing cover after feeding; Turn on the motor 101 to stir to speed up volatilization;

[0068] S3: The heating medium is introduced through the first medium inlet 6 and the second medium inlet 8, and forms a thermal cycle with the first medium outlet 7 and the second medium outlet 9, so as to raise the temperature of the organic mixture to the gasification temperature, so that the temperature of the air temperature is relatively low. ...

Embodiment 2

[0072] A method for a purification device for volatile chemical organic compounds, comprising the following steps:

[0073] S1: Turn on the vacuum pump 23 for pumping and reducing pressure to ensure that the tank is in a vacuum state;

[0074] S2: Turn off the vacuum pump 23, add chemical substances including two kinds of volatile organic compounds into the tank body provided with the stirring mechanism 10 and communicated with the condensation tank 14 through the feed port 12, and seal the feed port 12 through the sealing cover after feeding; Turn on the motor 101 to stir to speed up volatilization;

[0075] S3: The heating medium is introduced through the first medium inlet 6 and the second medium inlet 8, and forms a thermal cycle with the first medium outlet 7 and the second medium outlet 9, so as to raise the temperature of the organic mixture to the gasification temperature, so that the temperature of the air temperature is relatively low. The low organic matter reaches...

Embodiment 3

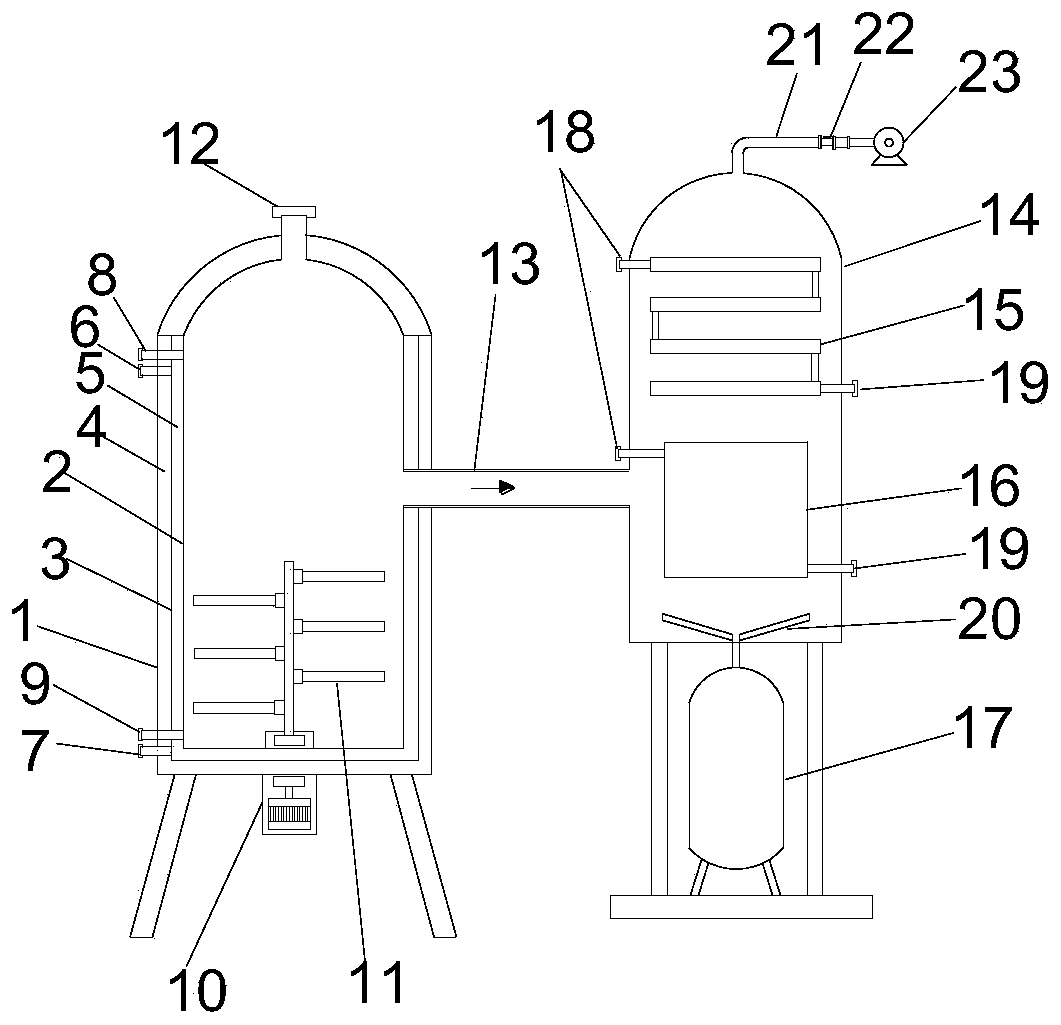

[0083] Such as Figure 2-6 As shown, a purification device for volatile chemical organic compounds; includes a tank body and a condensation tank 14; the tank body includes an outer tank 1 and an inner tank 2, and the outer tank 1 is a cylinder structure with both ends closed, and the An inner tank 2 is arranged inside the outer tank 1, and a partition 3 is arranged between the inner tank 2 and the outer tank 1. It is the second cavity 5; the bottom of the tank is provided with a stirring mechanism 10; the side of the tank is provided with a connecting pipe 13, and the connecting pipe 13 communicates with the condensation tank 14, and the inside of the condensation tank 14 is provided with The first condensation mechanism 15 and the second condensation mechanism 16; the bottom of the condensation tank 14 is provided with a recovery tank 17 .

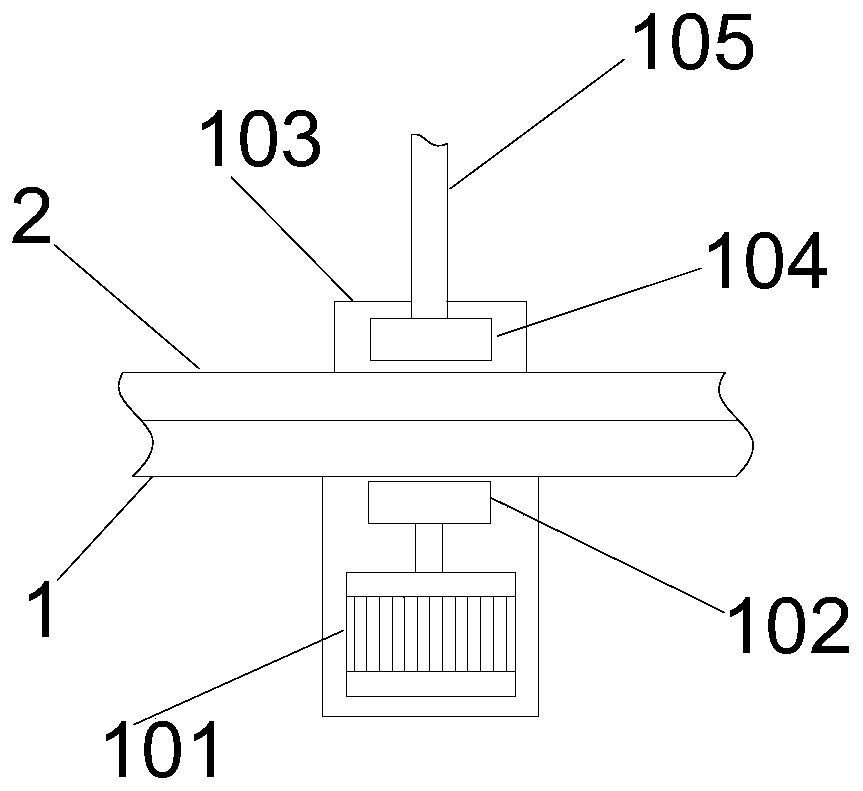

[0084] Described stirring mechanism 10 comprises motor 101, and described motor 101 is arranged on the bottom of outer tank 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com