Low voltage mercury vapous discharge lamp, illuminating apparatus and display device

A discharge lamp and mercury technology, which is applied in the direction of low-pressure discharge lamps, lighting devices, gas discharge lamp components, etc., can solve the problems of increased gap, increased light loss, and reduced efficiency, and achieve the reduction of inner tube diameter, Effect of reducing light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

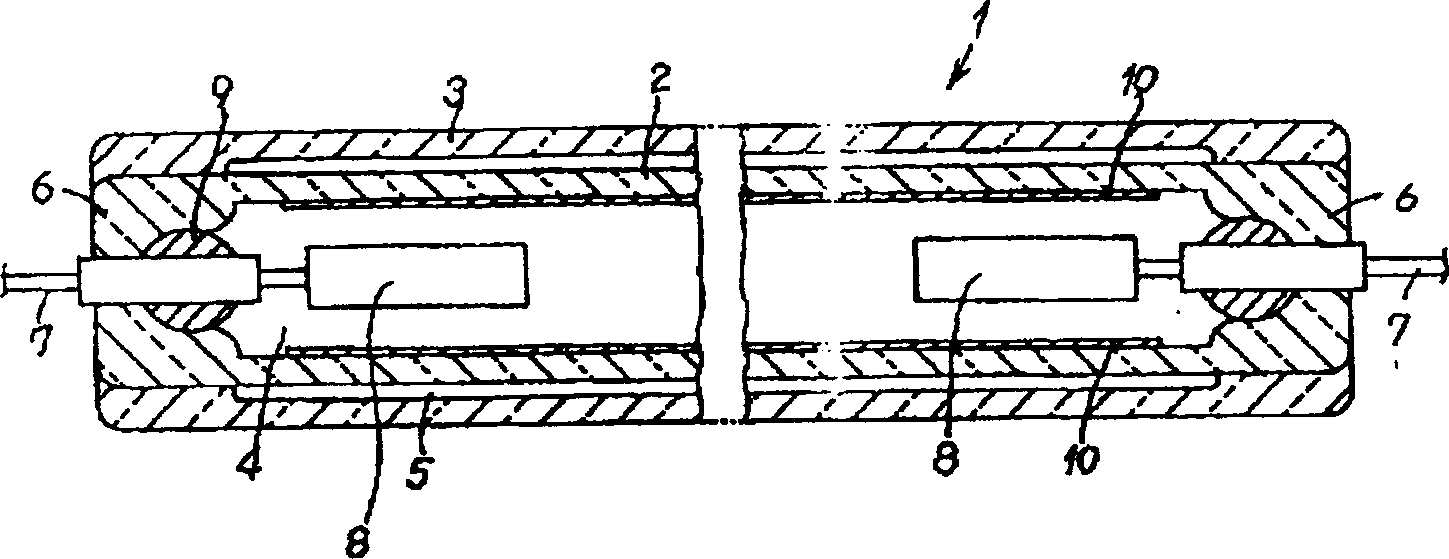

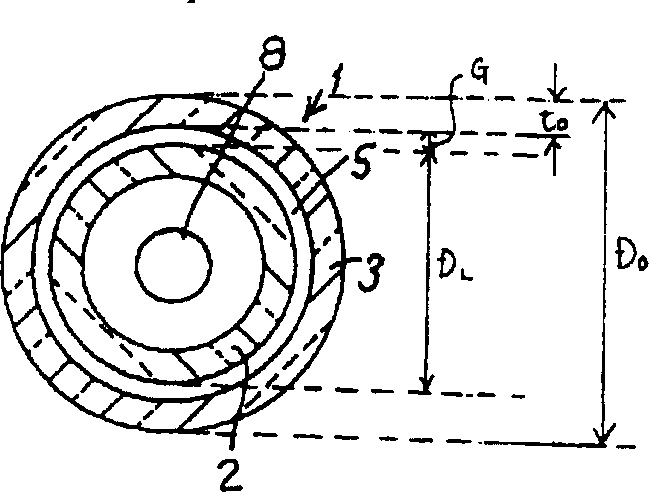

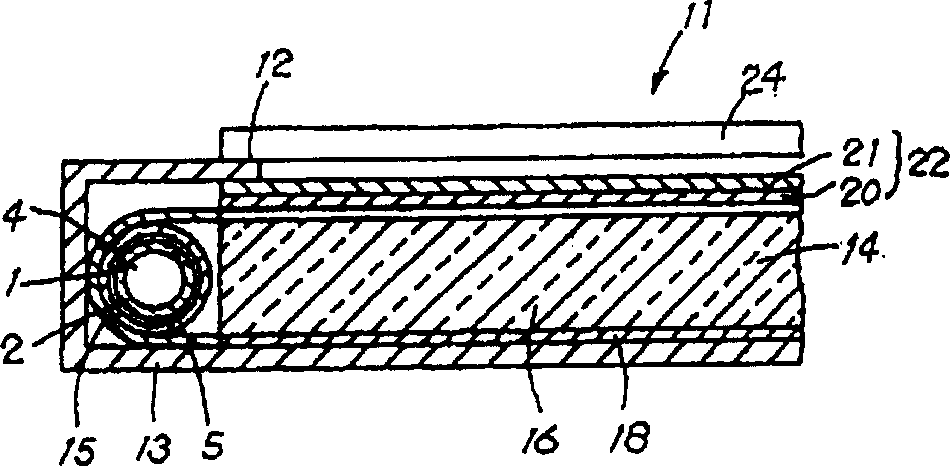

[0047] figure 1 To show a cross-sectional view of a low-pressure mercury vapor discharge lamp, figure 2 In order to show the longitudinal cross-sectional view of the low-pressure mercury vapor discharge lamp, it is conceptually shown, and the detailed shape and size are accurately drawn.

[0048] Such as figure 1 and figure 2 As shown, the low-pressure mercury vapor discharge lamp 1 has a straight tubular arc tube 2 of borosilicate glass with Corning product number 7050 as an inner tube, and the arc tube 2 is coaxially formed with the same boron as the arc tube 2. The outer tube 3 made of silicate glass forms a discharge circuit 4 in the luminous tube 2, a gap 5 is formed between the luminous tube 2 and the outer tube 3, and an integrated seal is formed at both ends of the luminous tube 2 and the outer tube 3 section. Corning's borosilicate glass with product number 7050 has a thermal expansion rate of 46×10 -7 / ℃. In addition, the luminous tube 2 and the outer tube 3 may als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com