Construction method of prestress common pipe ditch

A construction method and common pipe technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of high steel consumption, troublesome construction process, and consumption of water-stop steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

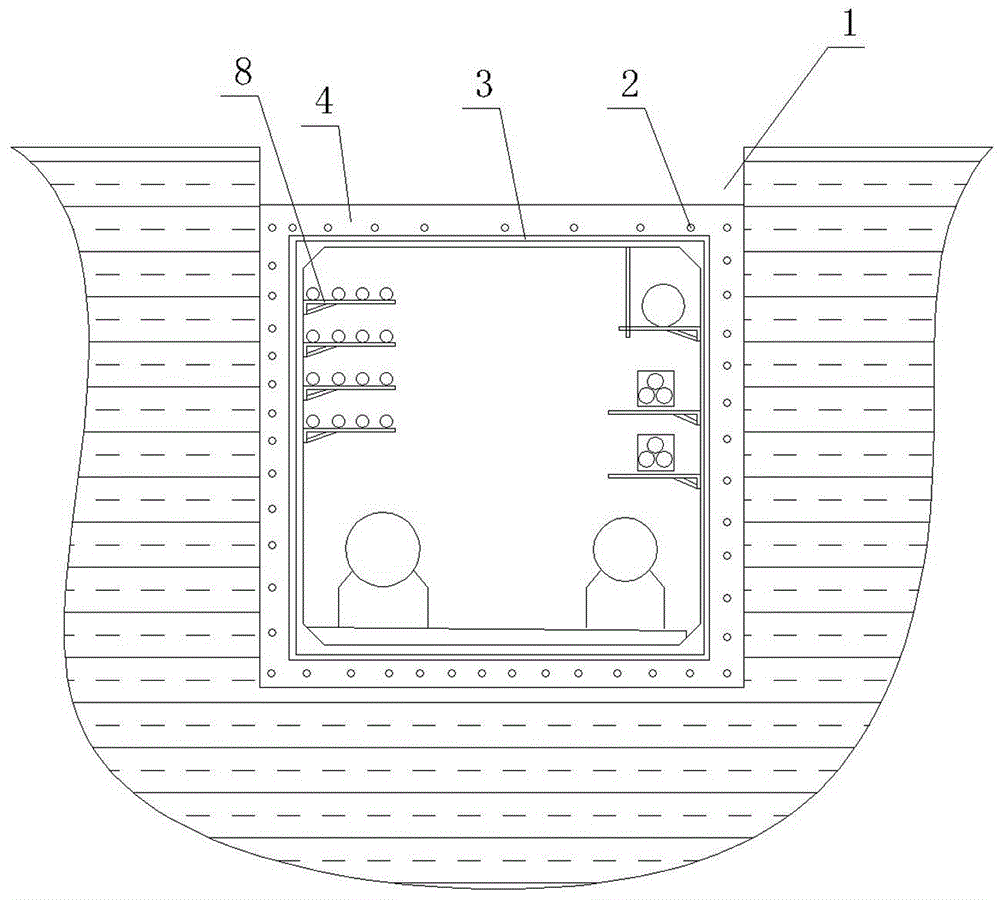

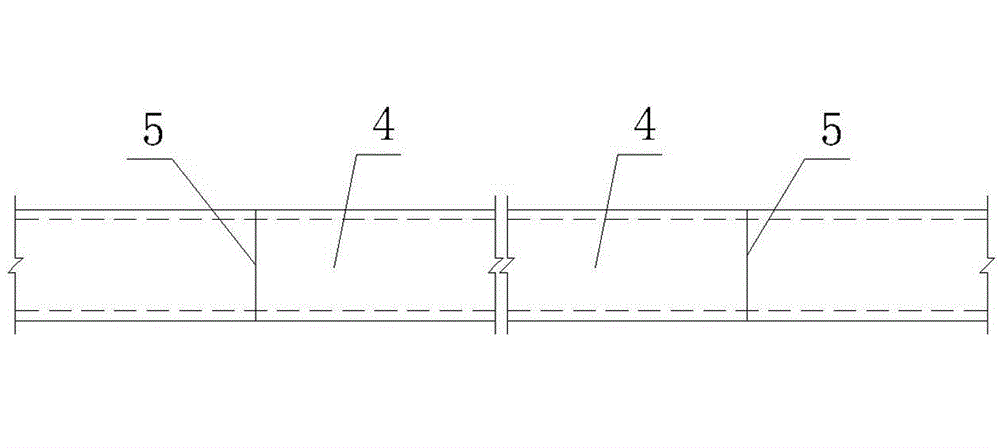

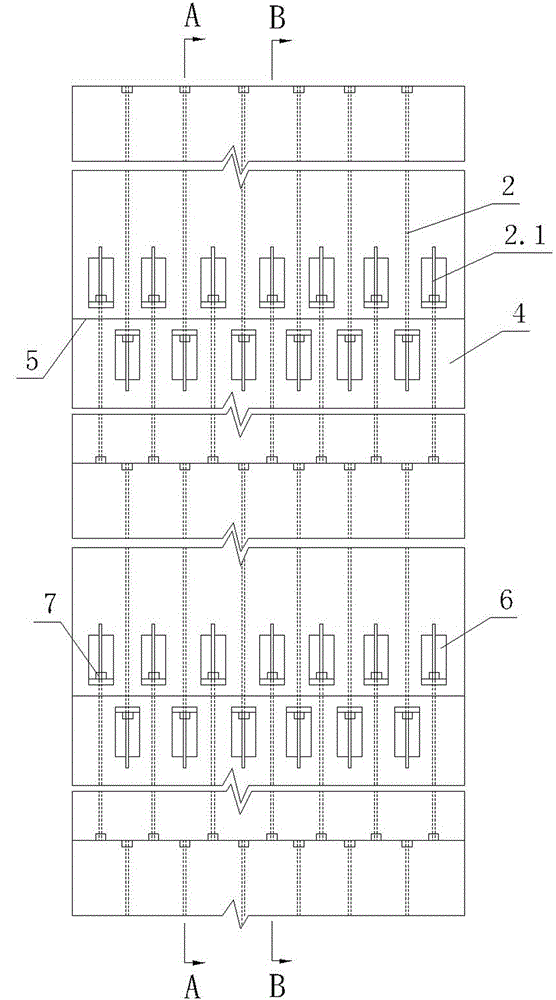

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 The construction method of the prestressed common trench of the present invention shown, it comprises the following steps.

[0036] a. Excavate the trench 1 for accommodating the prestressed common pipe trench.

[0037] b. Bind and fix the hoop-direction steel bars and the longitudinal or length-wise steel bars and lay the formwork. The longitudinal steel bars include non-prestressed steel bars and prestressed steel bars 2. Wherein, the rear ends of prestressed steel bars 2 in odd sections are warped outward, and the front ends of prestressed steel bars 2 in even sections are warped outwardly, and a sleeve is fixed to the warped end 2.1 of each prestressed steel bar 2 . There is a ring of water-stop steel plates 3 between the prestressed steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com