Adaptive power semiconductor module reliability test testing clamp

A power semiconductor, test and test technology, applied in the direction of single semiconductor device testing, measuring device casing, etc., can solve the problem of affecting the heat conduction and heat dissipation of the module bottom plate, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] 1. Design points of the present invention

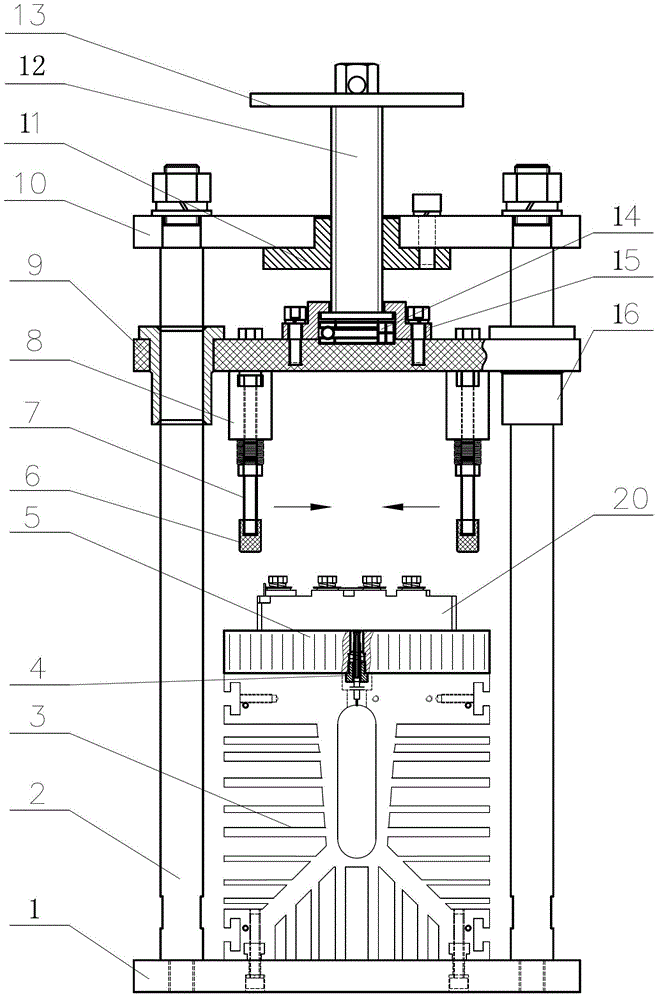

[0013] 1) Overall Mechanism Design

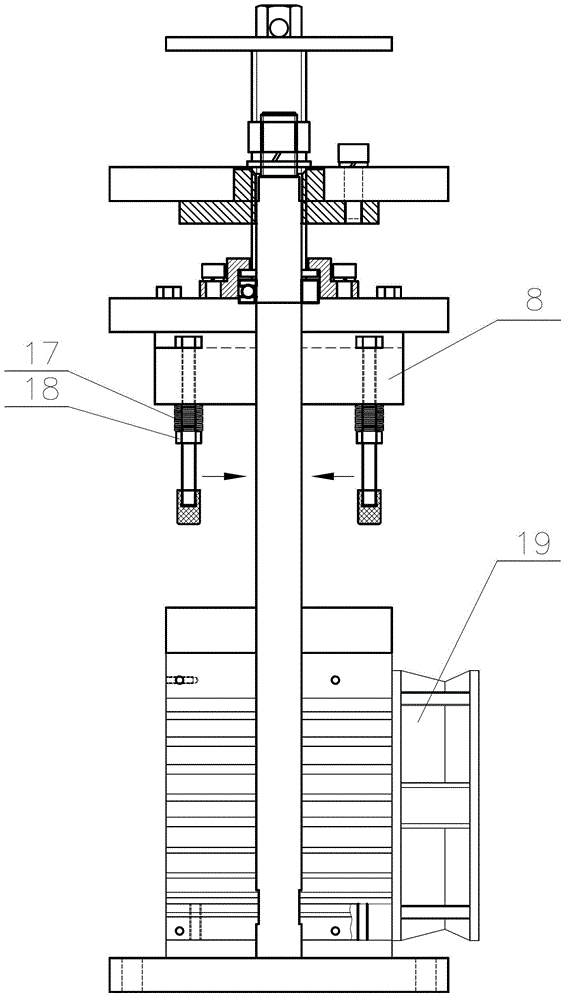

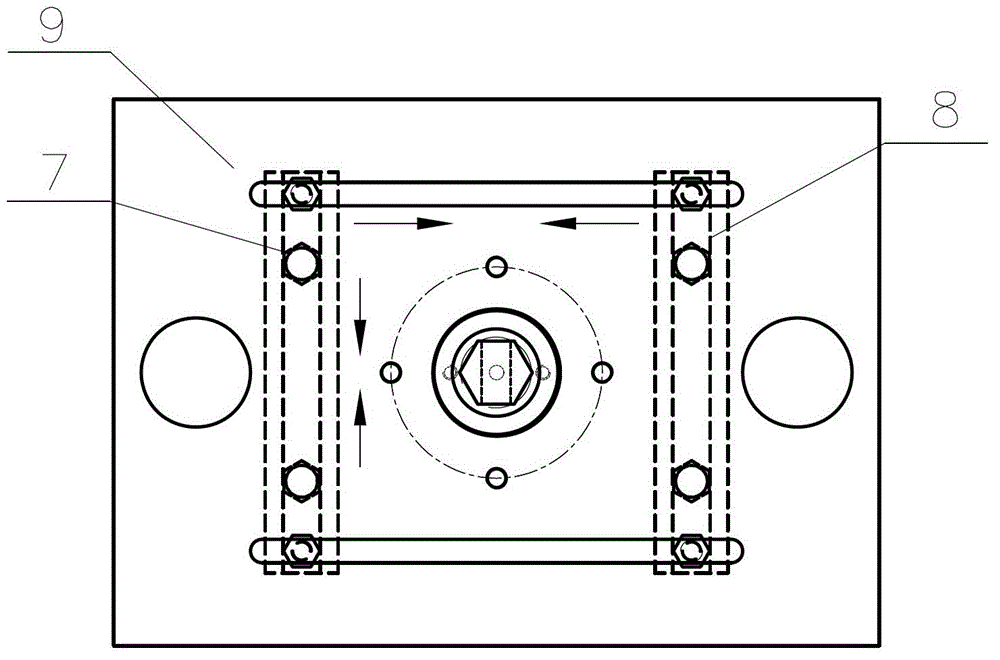

[0014] Adaptive power semiconductor module reliability test test fixture includes fixed plate 1, guide rod 2, radiator 3, heating plate 5, end thermal resistance 4, front and rear support screws 7, left and right sliding bars 8, sliding plate 9, upper fixing plate 10 and the trapezoidal screw 12, two guide rods 2 are fixed on the base plate 1, the upper fixed plate 10 and the upper end of the guide rod 2 are fixed to form a frame, the trapezoidal screw 12 is connected with the sliding plate 9 through the thrust bearing 14 and the screw connection sleeve 15, Rotating turntable 13 is housed on the trapezoidal screw 12, and guide sleeve 16 is installed on the sliding plate 9, and guide bar 2 passes guide sleeve 16 and can slide up and down, makes trapezoidal screw 12 and is fixed on upper fixed plate 10 by rotating turntable 13 The flange trapezoidal nut 11 rotates relatively, so that the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com