Combined wiring terminal component

A connecting terminal and combined technology, applied in the direction of connection, electrical components, conductive connection, etc., can solve the problems of inconvenient use, cumbersome and complicated, and failure to simplify the installation and wiring process, so as to reduce wiring time and wiring procedures and improve efficiency , The effect of simplifying the wiring steps and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

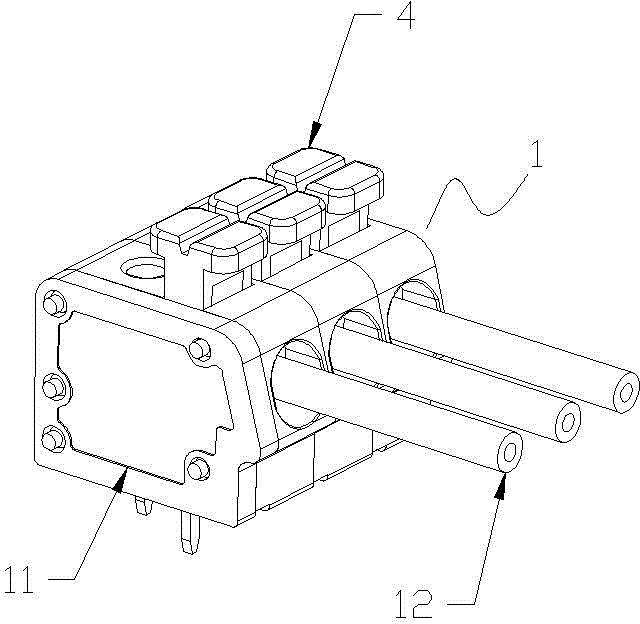

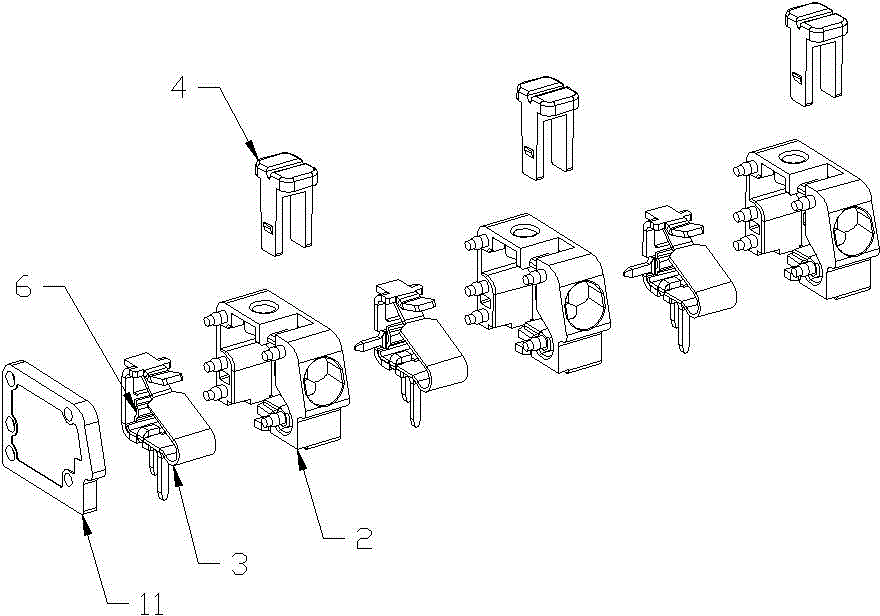

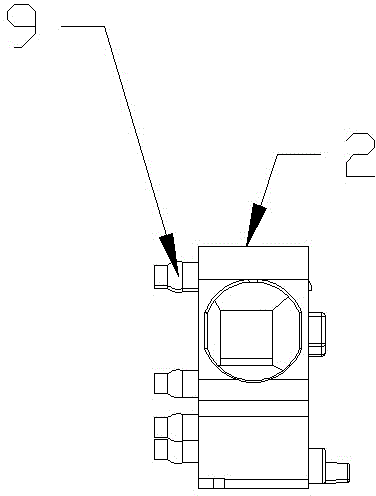

[0030] A combined terminal assembly described in Embodiment 1 of the present invention, such as figure 1 , figure 2 , image 3 , Image 6 , Figure 7 , Figure 8 As shown, the terminal block assembly is composed of three independent terminal blocks 1 assembled, each terminal block includes an insulating housing 2, a conductive metal sheet 3 for connecting wires 12 is provided in the insulating housing, and a conductive metal sheet 3 is provided on the insulating housing. A button 4 for disconnecting the wire and the conductive metal sheet; the terminal assembly is provided with a conduction device for connecting each conductive metal sheet or adjacent conductive metal sheets. The conductive metal sheets that need to be connected are connected in series through the conduction device, and the parallel connection of each wire can be realized after the wire is inserted into the corresponding terminal and connected with the conductive metal sheet. This combined terminal assem...

Embodiment 2

[0036] This embodiment 2 is changed on the basis of embodiment 1, and its specific changes are as follows: Figure 9 , Figure 10 As shown, the metal insert is set to the right, and the metal socket is set to the left.

Embodiment 3

[0038] This embodiment 3 also changes on the basis of embodiment 1, and its specific changes are as follows: Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 As shown, the conduction device is a metal straight strip 7 that is connected to conduction of each conductive metal sheet 3 . All the conductive metal sheets to be connected in series can be connected through a metal straight strip, which is simple and direct, and does not need to be provided with metal inserts and metal sockets on each conductive metal sheet.

[0039] Further, the structures of the conductive metal sheets are the same, and each conductive metal sheet is provided with a bayonet 8 that allows the straight metal strip to pass through, and each bayonet is connected to the straight metal strip. The bayonet can fasten the metal straight bar, so that the metal straight bar is not easy to come out, and accidents are prevented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com