Equipment for injecting chemical components into a stream of loose wood material

A technology for wood materials and chemical components, which is applied in the pretreatment of molding materials, wood processing appliances, household components, etc., and can solve problems such as the inability to guarantee crushing and homogenization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

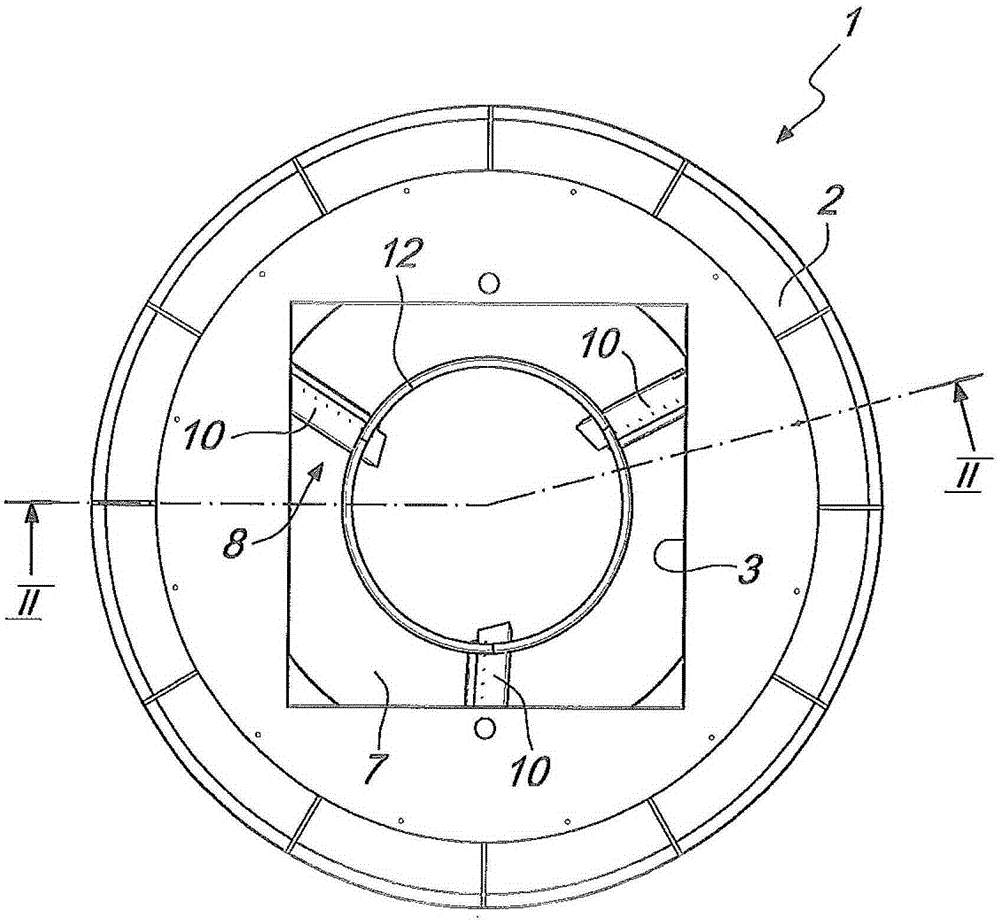

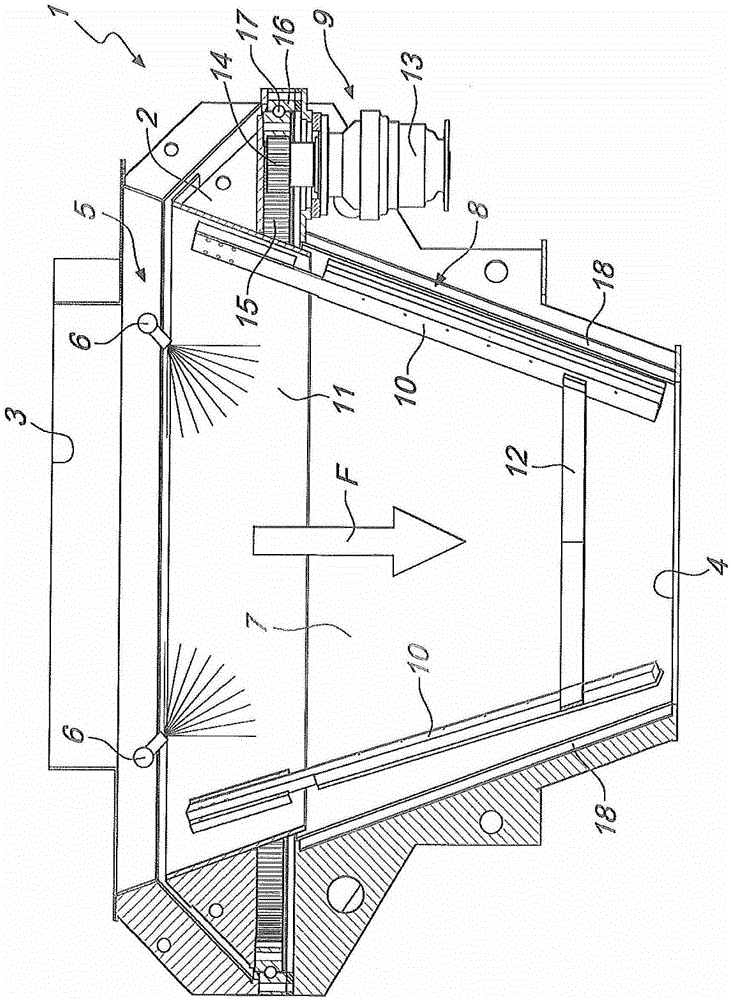

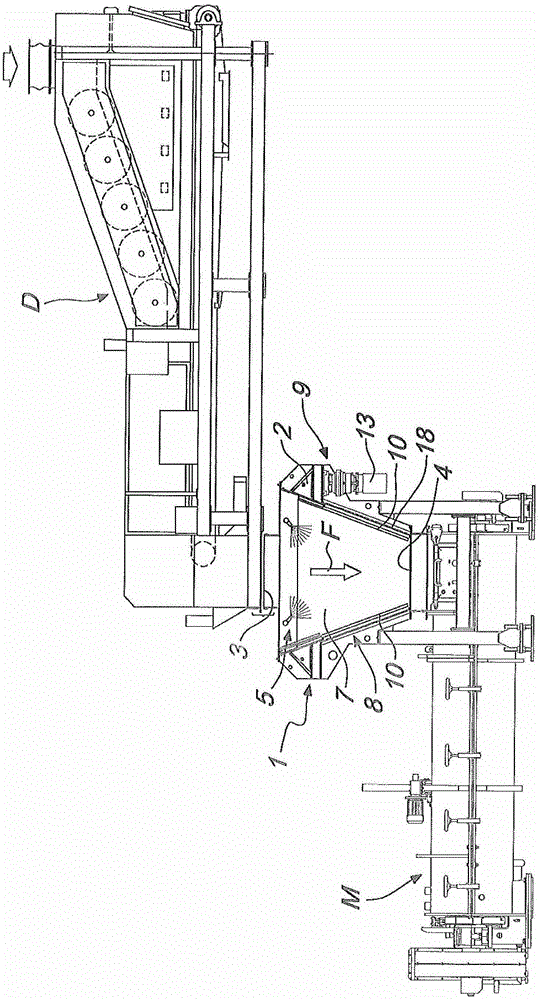

[0019] Referring to the drawings, reference numeral 1 generally indicates an apparatus for injecting chemical components into a stream of loose wood material.

[0020] In particular, in plants producing slats of chipboard, MDF (medium density fibreboard), OSB (oriented strand board), etc., the device 1 can be used to realize the combination of generally binding substances and additives with wood material particles (chips, chips , fiber, etc.) premix.

[0021] The apparatus 1 comprises a tubular body 2 extending along a longitudinal axis A, having at least one inlet 3 and at least one outlet 4, and inside said tubular body a flow of loose wood material passes from the inlet towards the outlet, in the figures the The flow of loose wood material is indicated by arrows indicated with the letter F.

[0022] In operating conditions, the device 1 is positioned with its longitudinal axis A not horizontal and preferably vertical, so that the inlet 3 is arranged above the outlet 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com