A system and method for pretreatment and upgrading of high-sodium and high-calcium coal in oxygen/carbon dioxide combustion

A carbon dioxide and combustion technology, which is applied in the field of high-sodium and high-calcium coal pretreatment and upgrading system, can solve the problem of difficult to remove calcium element in Zhundong coal, achieve high-efficiency combustion, realize water resources, and save cooling water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to understand the present invention more clearly, the present invention will be described in further detail below in conjunction with accompanying drawing:

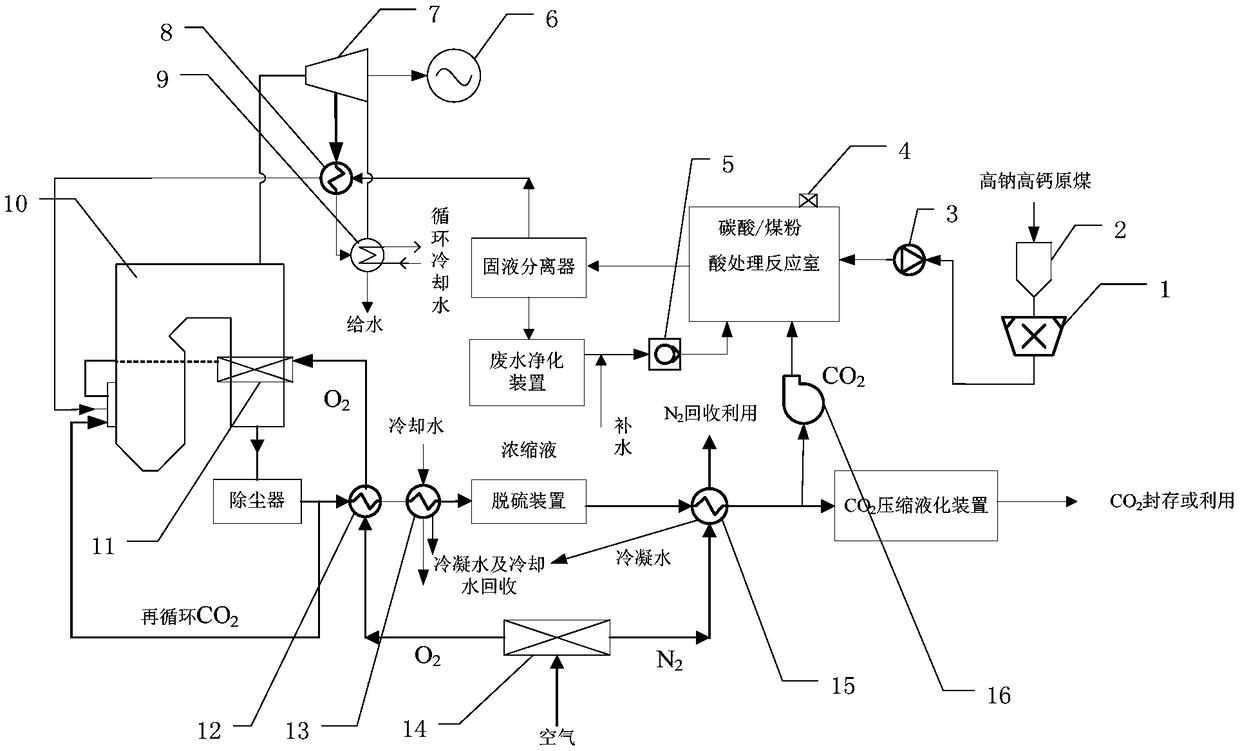

[0030] Such as figure 1 As shown, a pretreatment and upgrading system for high-sodium and high-calcium coal in oxygen / carbon dioxide combustion of the present invention includes a boiler 10, a steam turbine 7, a generator 6, a condenser 9, a dryer 8, a dust collector, and a first-stage gas - Gas heat exchanger 12, second stage gas-gas heat exchanger 15, gas-liquid heat exchanger 13, desulfurization device, CO 2 Compression liquefaction device, coal crusher 2, coal mill 1, air separator 14, coal feeding fan 3, carbonic acid / coal pulverized acid treatment reaction chamber, solid-liquid separator, waste water purification device, water pump 5 and fan 16.

[0031] During operation, the outlet of the superheater of the boiler 10 is connected to the main steam inlet of the steam turbine 7, and the steam turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com