Sorting machine and member checking apparatus

A sorting machine, technology of electronic components, applied in the field of sorting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

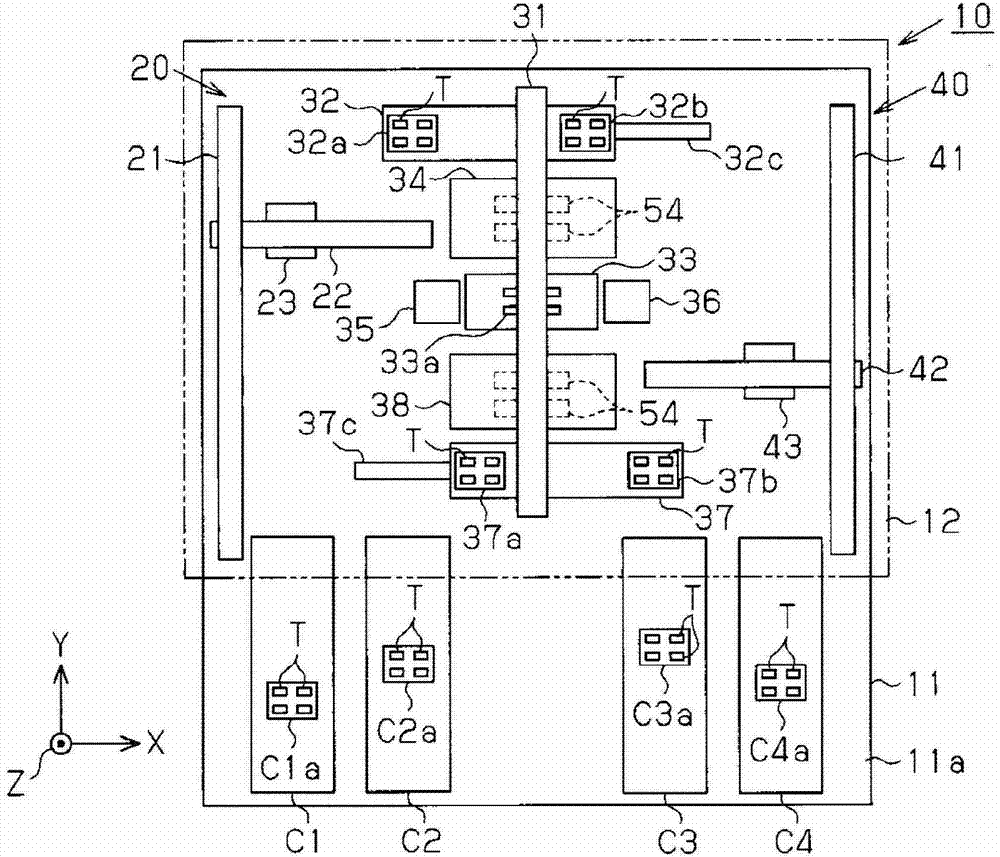

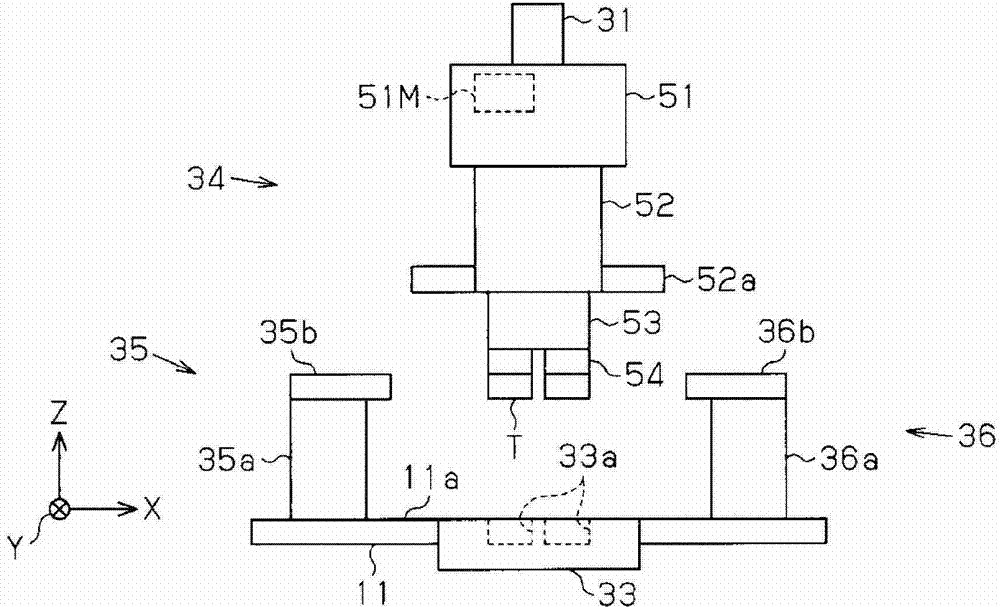

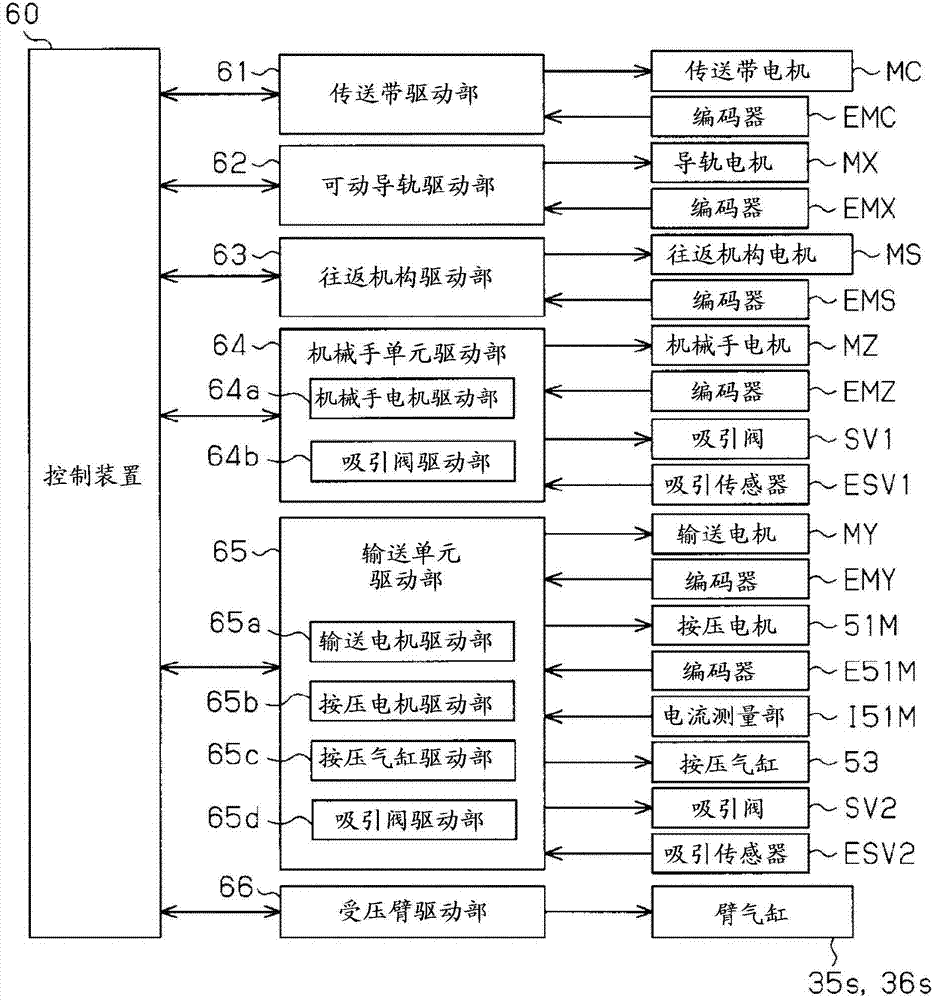

[0041] Refer to the following Figure 1~Figure 12 , an embodiment in which the sorter and the component inspection device of the present invention are embodied will be described. First refer to figure 1 The configuration of the component inspection device will be described.

[0042] Configuration of parts inspection device

[0043] Such as figure 1 As shown, on the base 11 of the sorter 10 included in the component inspection apparatus, a mounting surface 11 a on which various manipulators are mounted is provided as an upper surface, and most of the mounting surface 11 a is covered by a covering member 12 . The humidity and temperature of the conveyance space, which is a space surrounded by the covering members 12 and the mounting surface 11a, are maintained at predetermined values by dry air supplied from outside the parts inspection apparatus.

[0044] Four belts extending in one direction are arranged on the mounting surface 11 a of the base 11 , and the arrangement d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com