Automatic dust removing and oil applying system and working method thereof

An automatic dedusting and oiling technology, applied in the direction of cleaning methods using gas flow, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of uneven coating, easy falling off, low production efficiency, etc., and achieve dust removal Unclean, safe and reliable operation, and the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

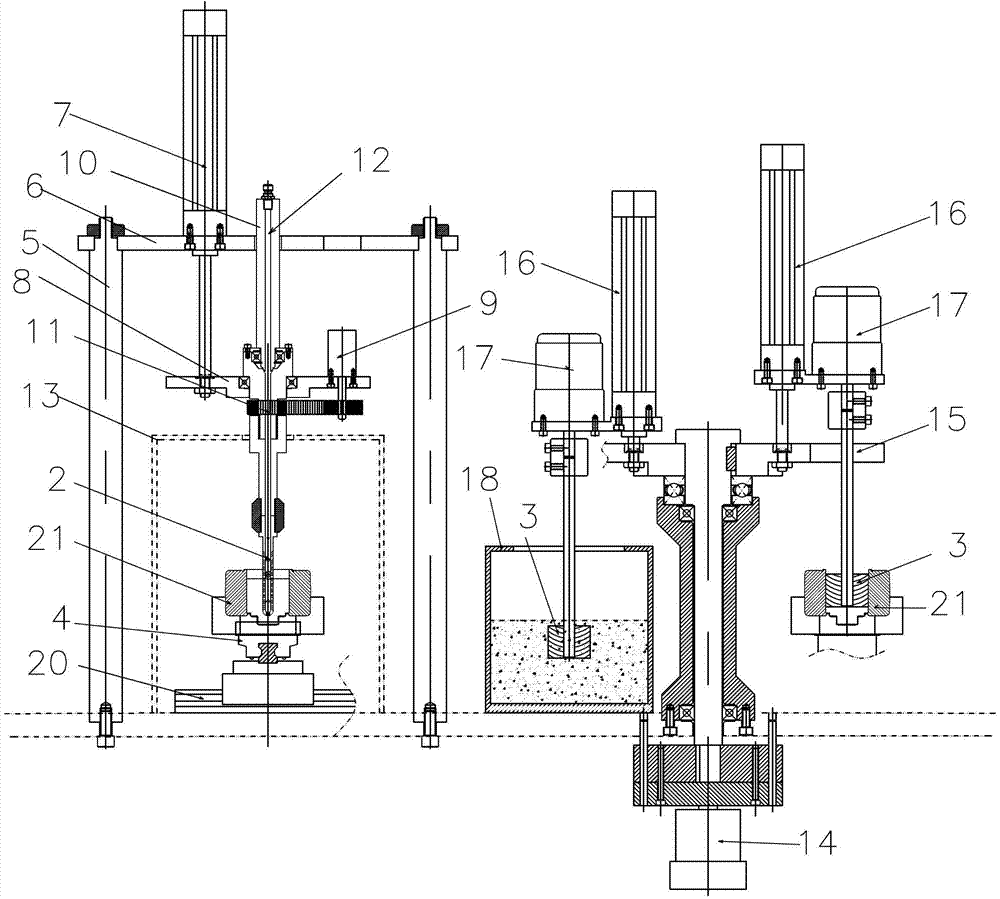

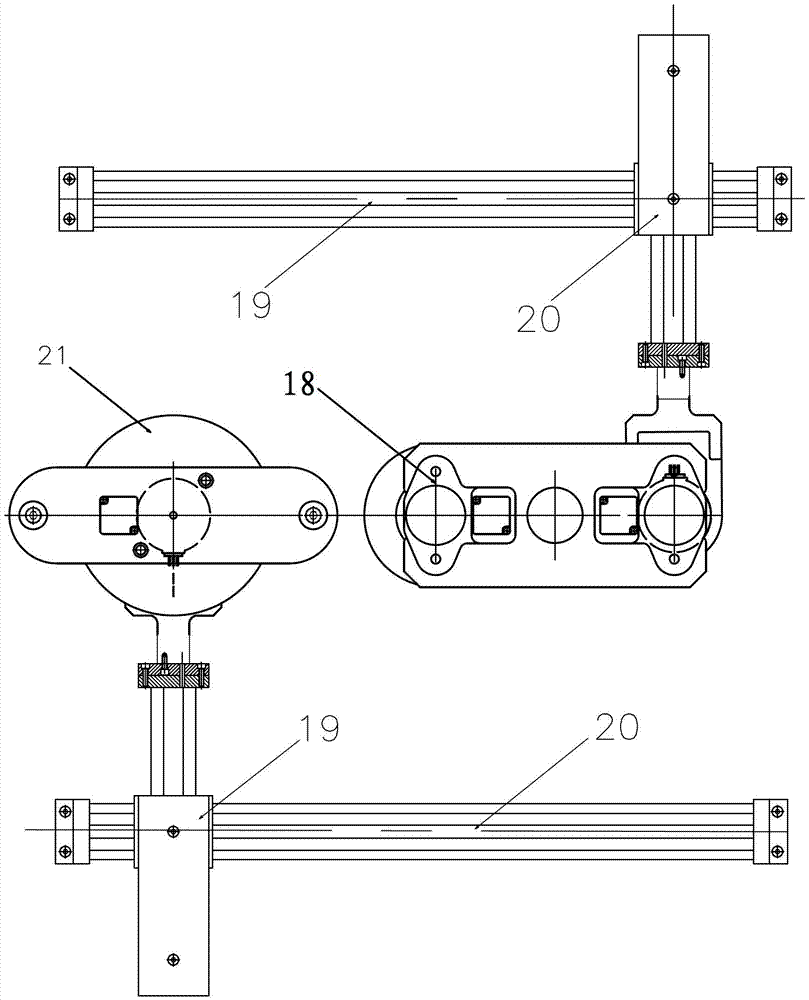

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 , 2As shown, the present invention comprises a frame body 1, a dust removal and purging device located on the frame body 1, an anti-rust oiling device, a transportation device and a control device for controlling the work of the dust removal and purging device, the anti-rust oiling device, and the transportation device, The dust removal and purging device includes a first lifting mechanism, a first rotating mechanism connected with the first lifting mechanism, and a purge rod 2 arranged on the rotating mechanism; the antirust oiling device includes an oil storage barrel 18, a transposition mechanism, and is located on the rotating mechanism. The second elevating mechanism on the transposition mechanism, the second rotating mechanism connected with the second elevating mechanism, the oiling brush 3 located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com