Scroll compressor with injection channel

A scroll compressor and injection channel technology, which is applied in the directions of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problem that the ratio of channel area to length is large, the channel opening cannot be optimized, and the channel design is complicated. and other problems, to achieve the effect of reducing noise, significant social benefits, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

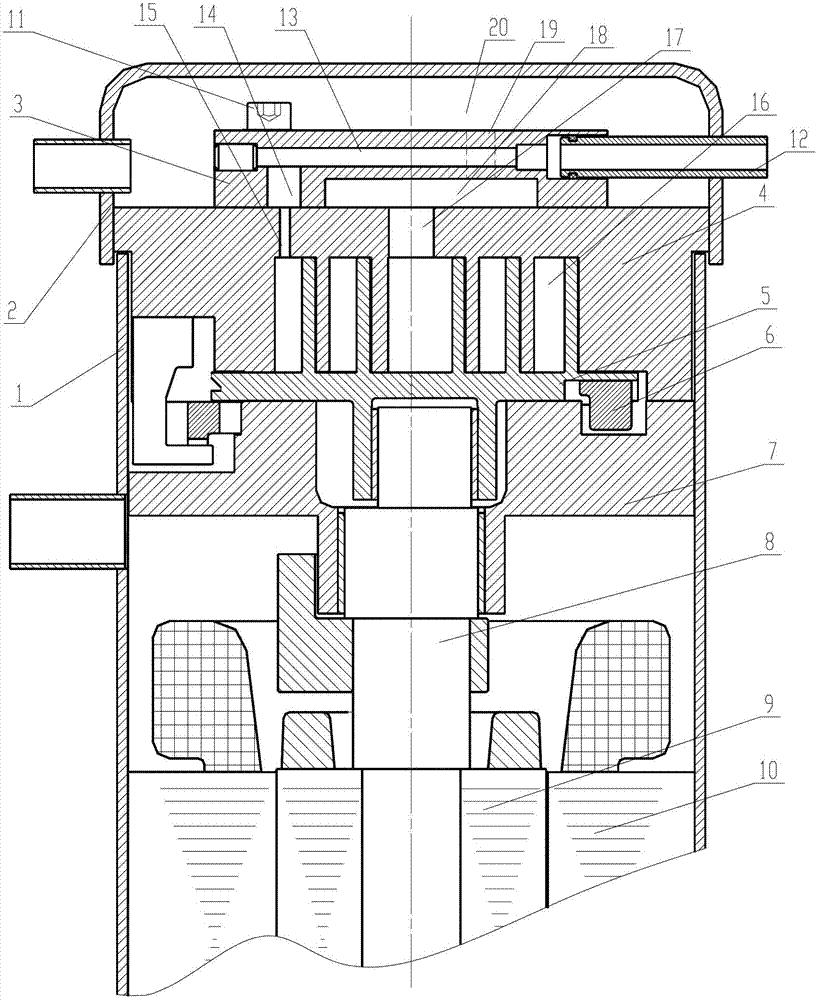

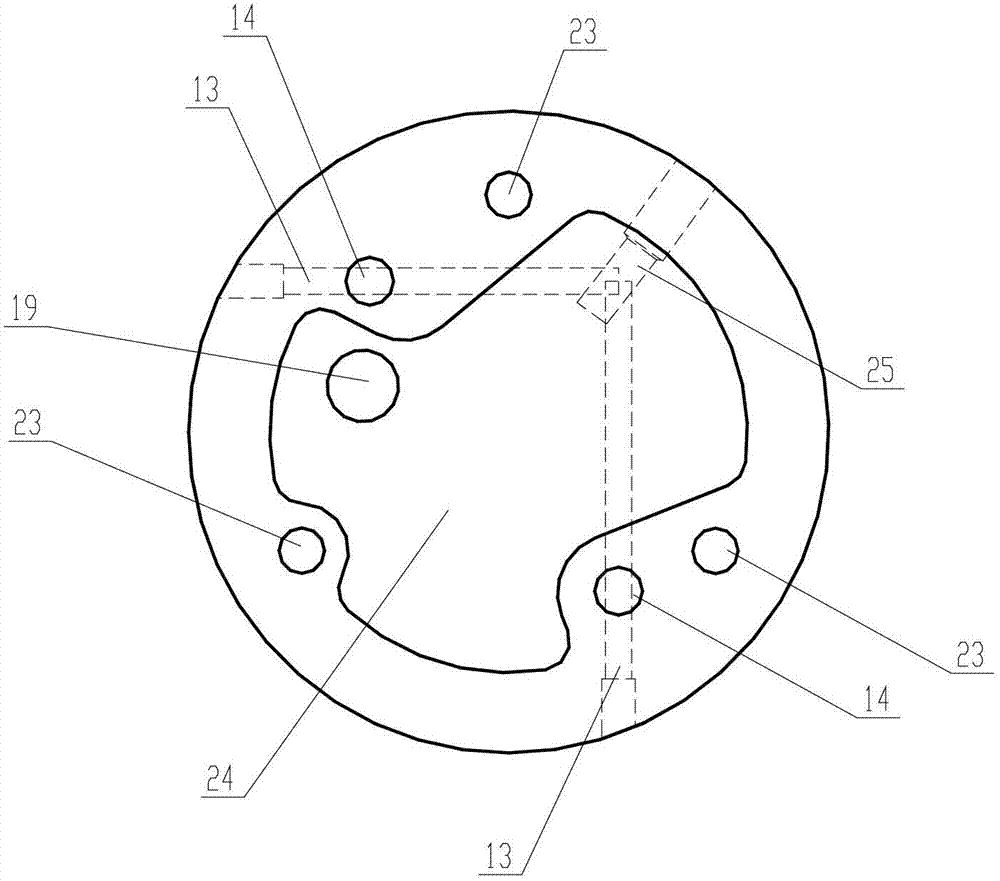

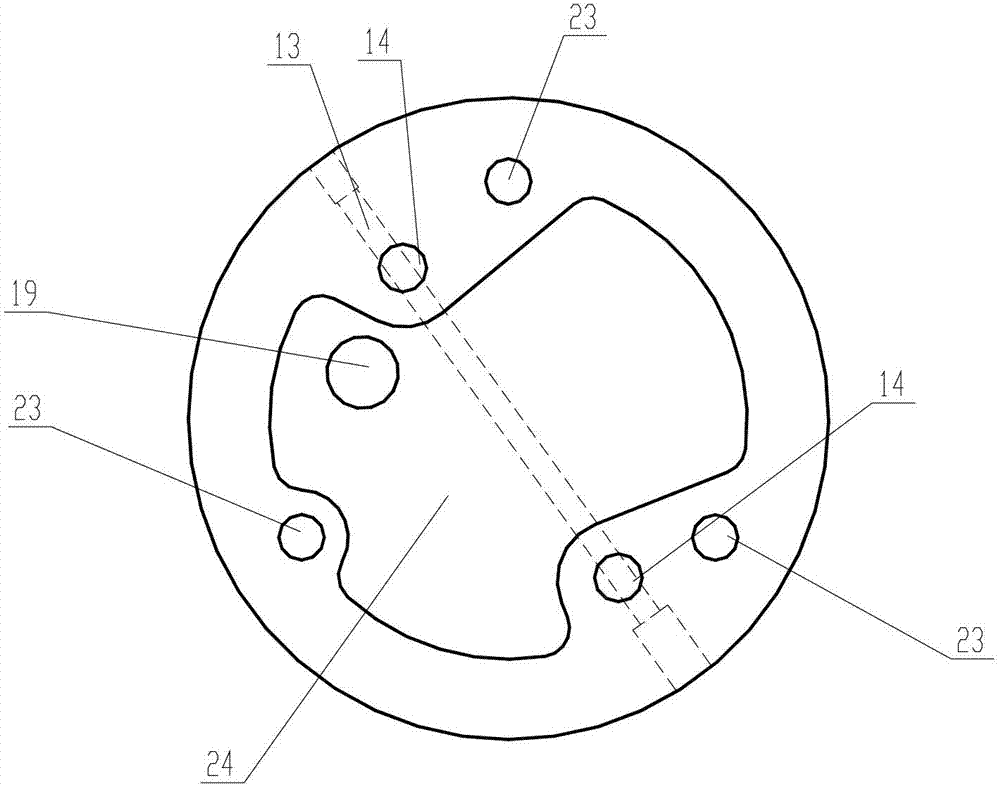

[0028] Specific examples of the present invention are attached Figure 4 As shown, it is composed of housing 1, upper cover 2, fixed scroll 4, movable scroll 5, Oldham ring 6, upper support 7, crankshaft 8, motor rotor 9 and motor stator 10; the motor stator 10 is fixed on In the lower part of the housing 1, the motor stator 10 is equipped with a motor rotor 9, and the motor rotor 9 is mounted on the bottom of the crankshaft 8, and the crankshaft 8 is equipped with an upper support 7 and a moving scroll 5, between the moving scroll 5 and the upper support 7 There is an Oldham ring 6 between them, the fixed scroll 4 is fixed on the upper support 7, the fixed scroll 4 and the movable scroll 5 cooperate to form a plurality of compression chambers 16, and the upper cover 2 is covered on the casing 1; the characteristic is that the valve The plate 3 is installed on the fixed scroll 4 through the bolt hole 23 and the screw 11 on it; the valve plate 3 is processed with the main injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com