Test-piece support for corrosion test

A corrosion test, test piece technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of limited test pieces, evaluation, limited quantity, etc., and achieve excellent chemical corrosion resistance and good insulation. and corrosion resistance, adjust the effect of ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

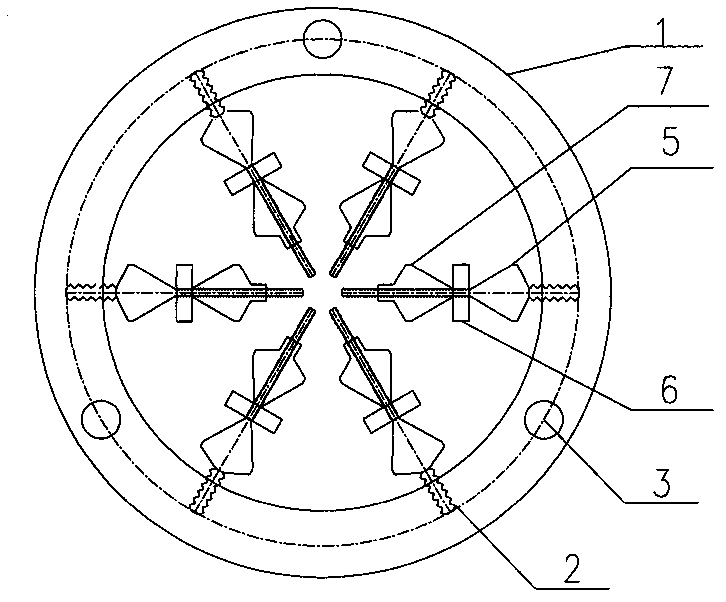

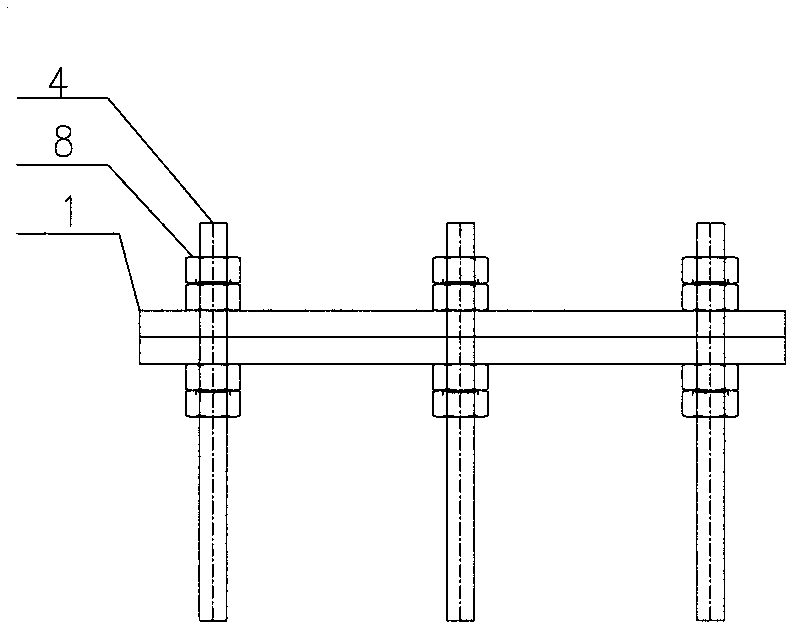

[0038] exist figure 1 and figure 2 Among them, the bottom of the ring 1 is provided with 3 circular positioning holes evenly distributed, the support rod 4 is inserted into the positioning hole 3, and fixed on the support rod by the nut 8, and the inner side of the ring 1 is provided with 6 threads evenly distributed Groove 2; one end of the hanger rod 5 is threadedly connected in the threaded groove 2 of the ring 1, and the other end of the hanger rod 5 can penetrate the test piece, and then the cover locator 7 is fixed. The corrosion test specimen holder can hang six test specimens at one time, which can fully improve the efficiency of corrosion evaluation.

Embodiment 2

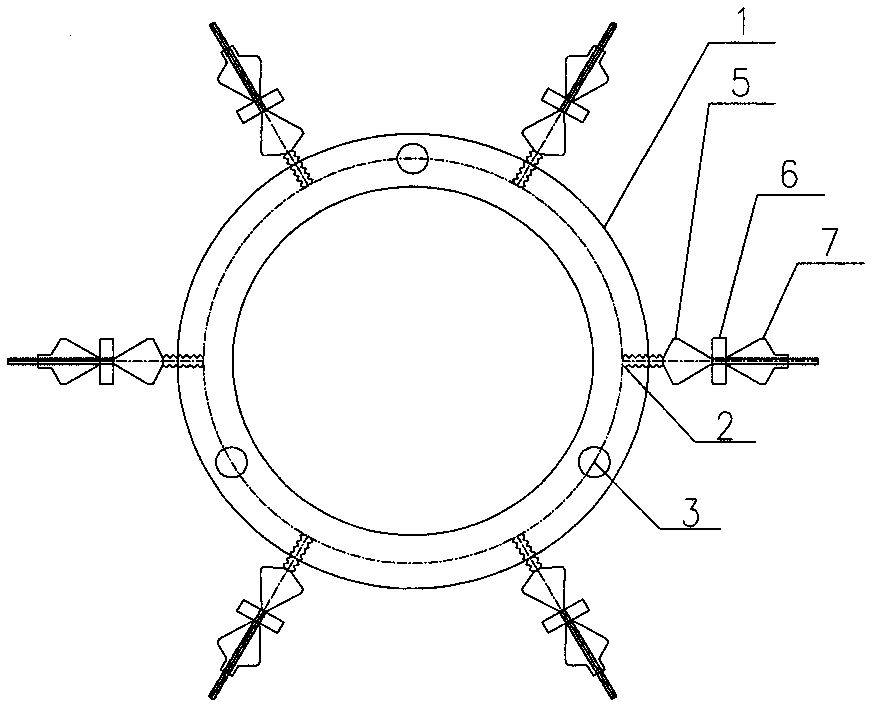

[0040] exist image 3 and Figure 4 Among them, the difference from Example 2 is that the corrosion test specimen bracket is a double-layer structure, the outside of the ring is slotted, and there are 6 slots on each layer. The assembly method is the same as that of Example 1. The corrosion test specimen The bracket can hang 6 test pieces in the vapor phase position in the corrosive medium, 6 in the liquid phase, and can hang 12 test pieces at one time, and the corrosion evaluation efficiency is further improved.

Embodiment 3

[0042] exist Figure 5 and Figure 6 Among them, the difference from Examples 1 and 2 is that the corrosion test specimen support has a three-layer structure, the outside of the ring is slotted, and there are 12 slots on each layer. The assembly method is the same as in Example 1. The corrosion test The test piece holder can hang 12 test pieces for the vapor phase position in the corrosive medium, 12 for the liquid phase, and 12 for the vapor-liquid interface, and a total of 36 test pieces can be hung. very significant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com