Method for rapidly detecting polyethylene tube special-purposed material grade

A technology of polyethylene pipes and special materials, applied in the field of grades, can solve problems such as practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

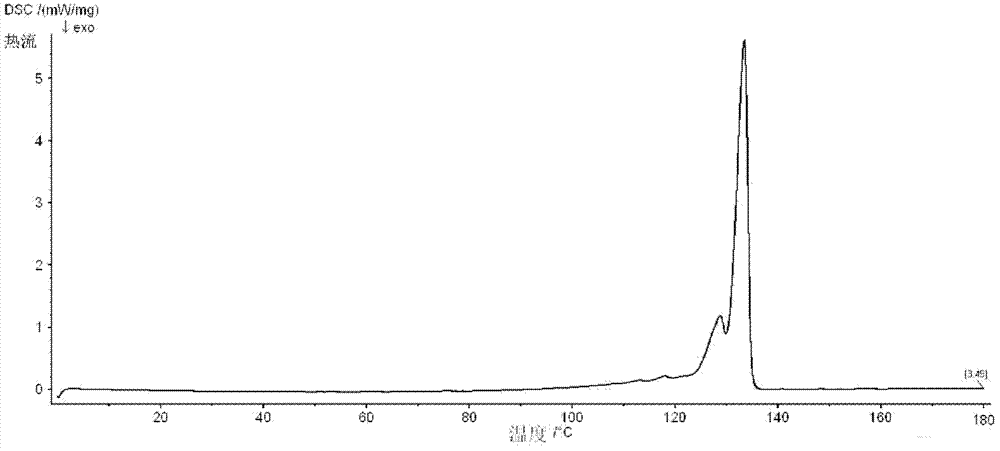

[0019] Example 1 Differential Scanning Calorimetry Thermal Grading Technology for Grade Judgment of PE Pipe Material

[0020] The DSC temperature rise scanning curves of two kinds of pipe material resin powders after continuous annealing self-nucleation technology are as follows: figure 1 and figure 2 shown. The integral areas corresponding to various melting peaks of the curves are given by the integral area percentages of the corresponding model curves, and the results are shown in Table 1.

[0021] The mass percentage analysis results of different sequence lengths (different wafer thicknesses) of the two samples of Table 1 PE1 and PE2

[0022]

[0023] Note: sample 1 and sample 2 are natural color powder respectively

[0024] According to the results in Table 1, it can be judged that the pipe material corresponding to the sample PE1 is PE63 or lower, and the pipe material corresponding to the PE2 sample is PE80 or higher. This result is consistent with the labeling...

Embodiment 2

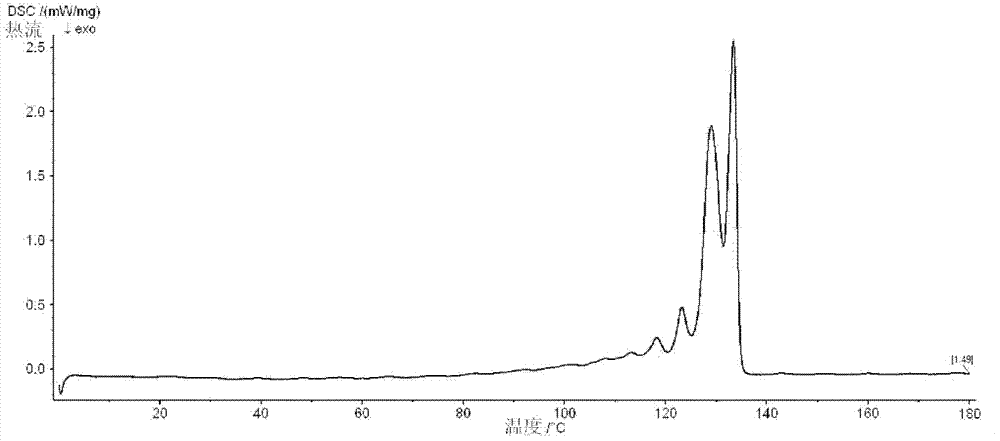

[0025] Example 2 Differential Scanning Calorimetry Thermal Grading Technology for Grade Judgment of PE Pipe Material

[0026] The DSC temperature rise scanning curves of the natural color pellets and mixed black materials of the two kinds of tube material resins after continuous annealing and self-nucleation technology are as follows: image 3 and Figure 4 shown. The integral areas corresponding to the various melting peaks of the curves are given by the integral area percentages of the respective corresponding model curves, and the results are shown in Table 2.

[0027] The mass percentage analysis results of different sequence lengths (different wafer thicknesses) of the two samples of Table 2 PE1 and PE2

[0028]

[0029] Note: Samples 1 and 1 are natural color materials of pellets; sample 2 is mixed black pellets. According to the results in Table 2, it can be judged that the pipe material corresponding to the sample PE1 is PE63 or lower grade, and the pipe material ...

Embodiment 3

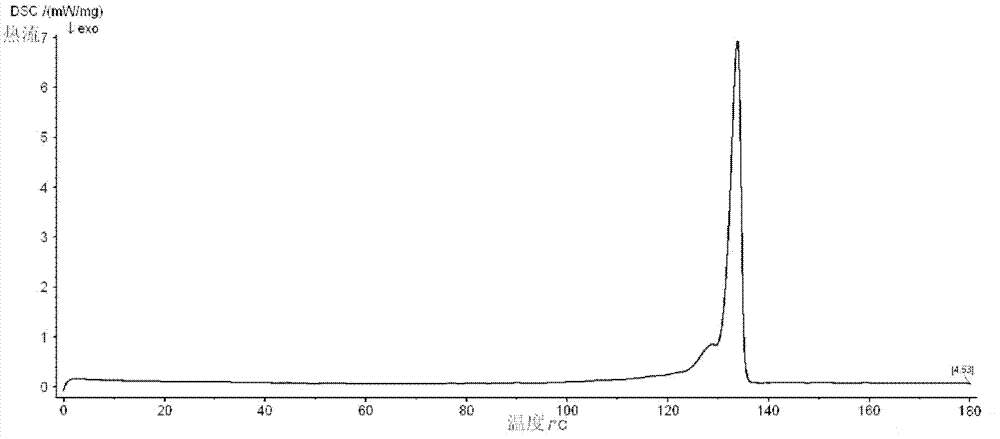

[0030] Example 3 Differential scanning calorimetry thermal classification technology determines the grade of PE pipe material The powder of two kinds of pipe material resins, the DSC temperature rise scanning curve after the continuous annealing self-nucleation technology treatment is as follows Figure 5 and Image 6 shown. The integral areas corresponding to various melting peaks of the curves are given by the integral area percentages of the corresponding model curves, and the results are shown in Table 3.

[0031] Table 3 The mass percentage analysis results of the different sequence lengths (different wafer thicknesses) of the two samples of PE1 and PE2

[0032]

[0033] Note: Samples 1 and 1 are natural color materials of pellets; Sample 2 is tube sheet

[0034] According to the results in Table 3, it can be judged that the pipe material corresponding to the sample PE1 is PE63 or lower, and the pipe material corresponding to the PE2 sample is PE80 or higher. This r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com