Manufacture method for electrical testing fixture

A production method and electrical measurement technology, which are applied in the directions of measuring devices, measuring electrical variables, manufacturing measuring instruments, etc., can solve the problems of wrong needle sleeve position sequence, failure to significantly improve the success rate of test fixture production, and low positioning accuracy, etc. Ensure accuracy, improve production efficiency and success rate, and ensure the effect of drilling position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for manufacturing an electric measuring fixture, comprising the following steps: fixture preparation → guide film light painting → guide film punching → guide film drilling → electric probe insertion → fixture wiring; details are as follows:

[0030] 1) Prepare the electrical measuring fixture according to the following process: file making→cutting→punching→drilling→hole position detection→drilling and sinking→milling the shape→assembly and finalization.

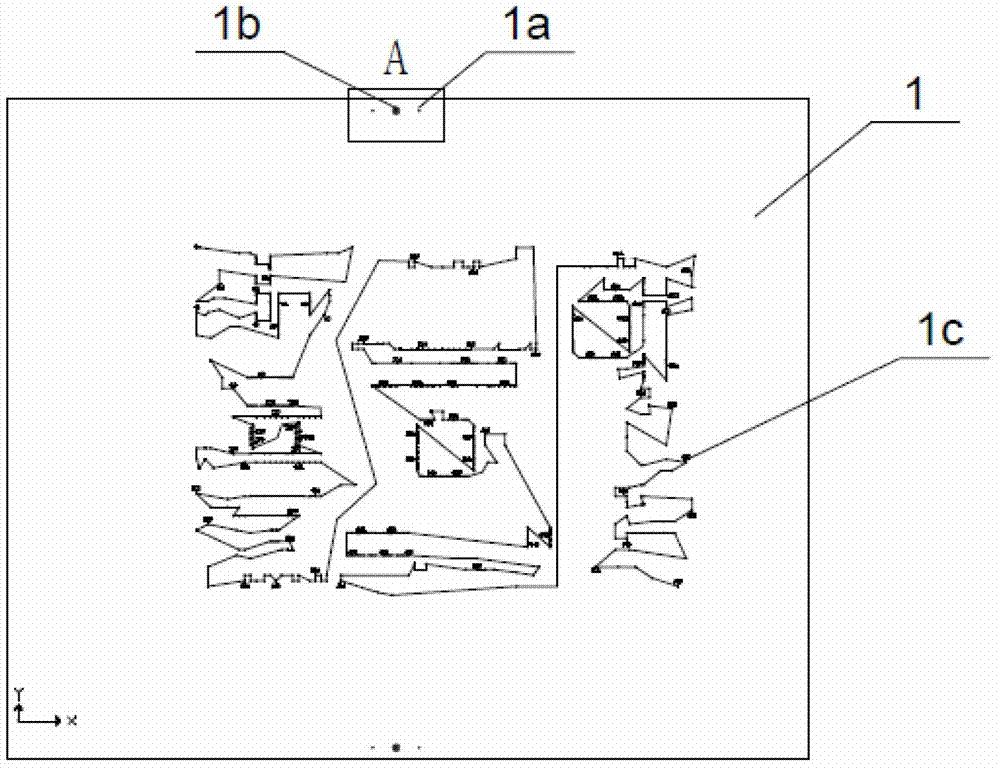

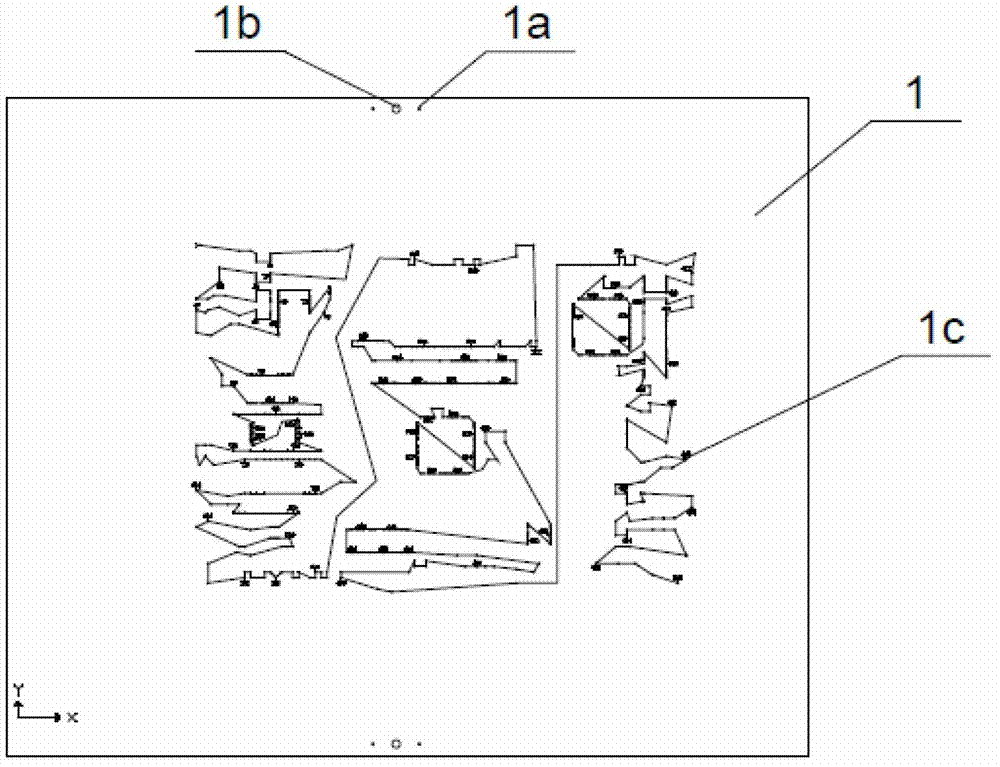

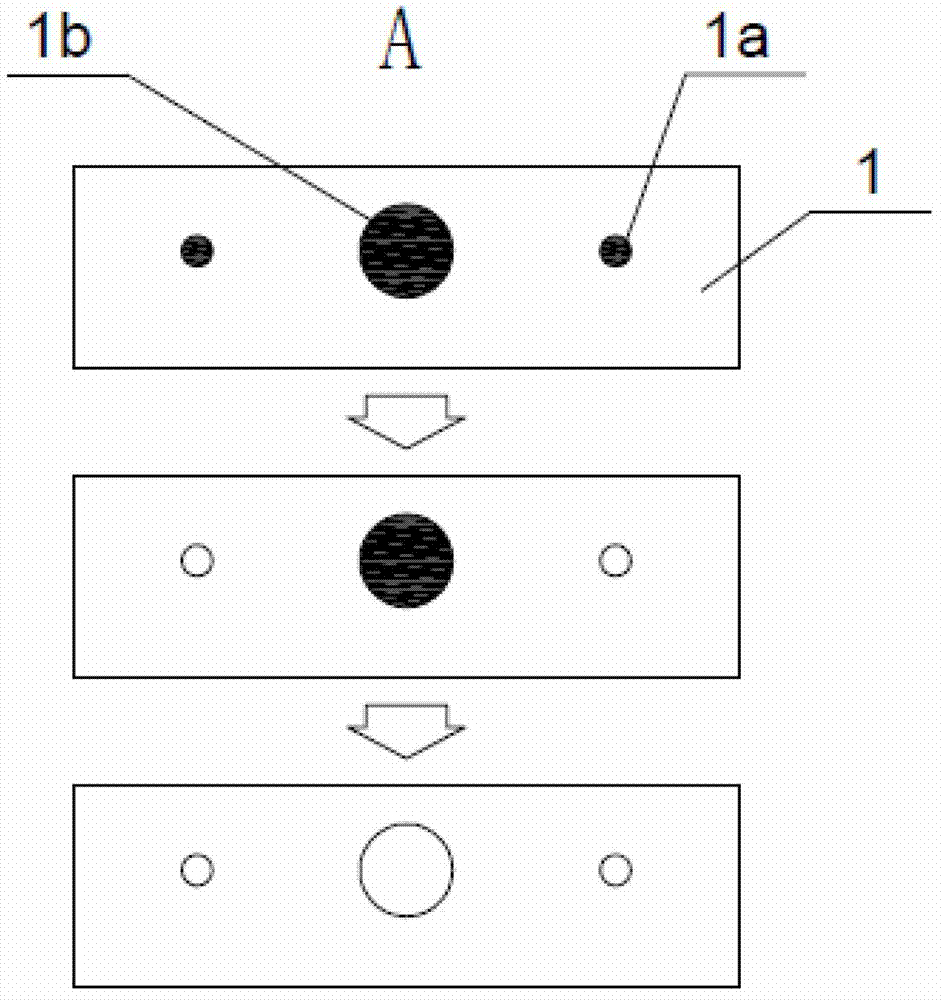

[0031] 2) figure 1 It is a schematic diagram of the design structure of the guide film of the present invention. As shown in the figure, according to the prepared document light drawing guide film 1, two punching holes with a diameter of ∮1.0mm are respectively arranged on the two corresponding sides of the guide film. Positioning hole 1a and a drilling pin positioning hole 1b with a diameter of ∮3.0mm; and, on the guide film, there is an indication pattern 1c for the insertion position of the electric test p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com