Lithographic apparatus, substrate table and device manufacturing method

A substrate table and substrate technology, applied in the field of manufacturing devices, can solve problems such as deformation, calculation errors, hindrances to miniaturization and the use of multiple detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

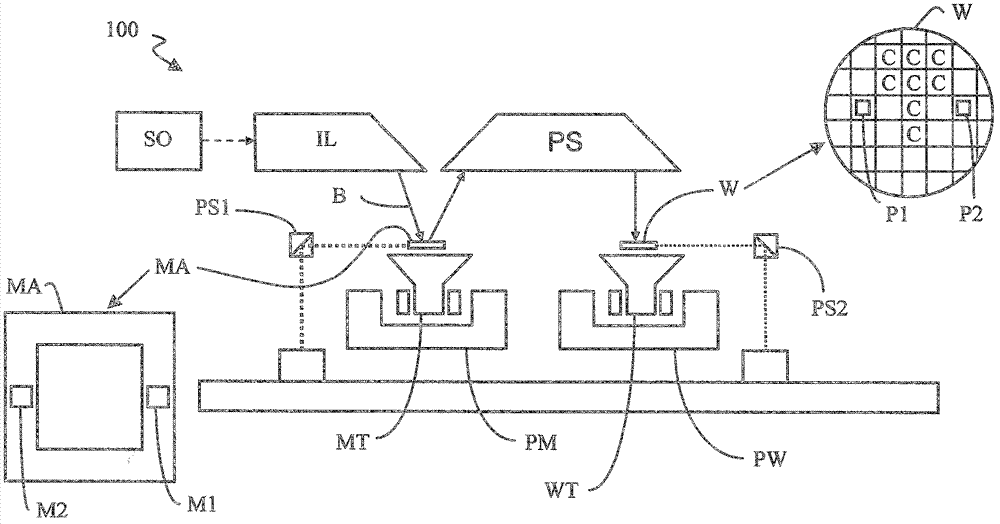

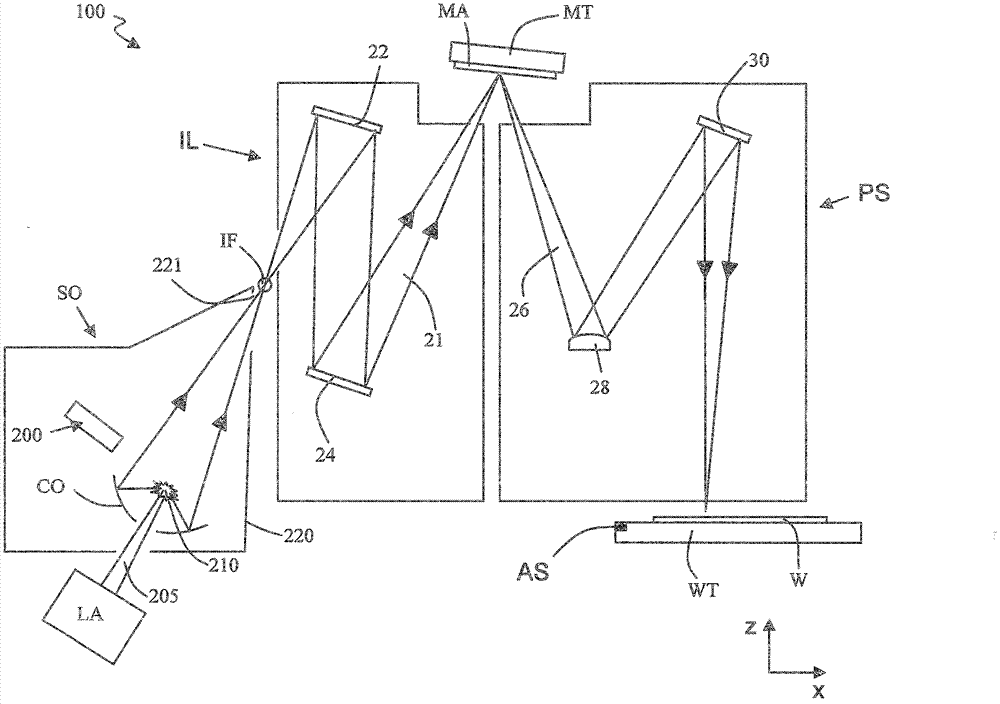

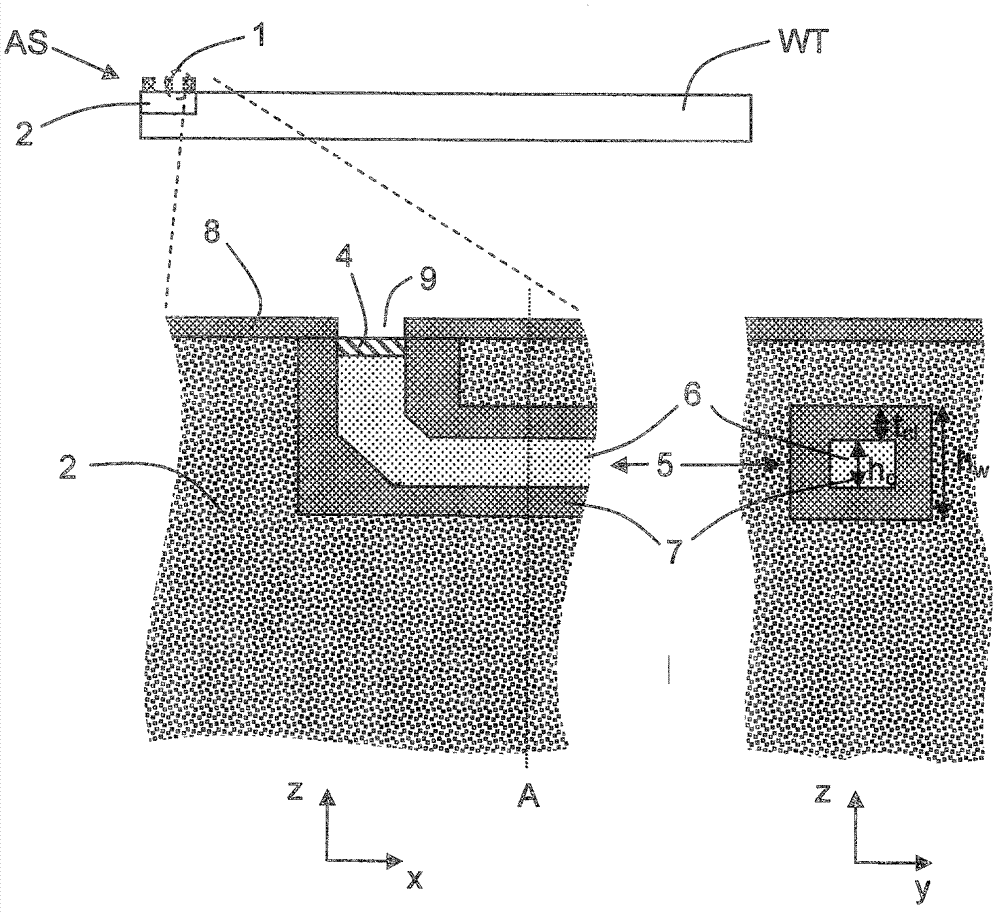

[0044] figure 1 A lithographic apparatus 100 comprising a source collector module SO according to an embodiment of the present invention is schematically shown. The lithographic apparatus comprises: an illumination system (illuminator) IL configured to condition a radiation beam B (e.g. EUV radiation); a support structure (e.g. a mask table) MT configured to support a patterning device (e.g. A mask or reticle) MA, and is connected to a first positioning device PM configured to accurately position the patterning device MA; a substrate table (such as a wafer stage) WT, which is configured to hold a substrate (such as coated with Resist wafer) W, and is connected with the second positioning device PW that is configured to accurately position substrate W; The pattern of beam B is projected onto a target portion C of substrate W (eg, comprising one or more dies).

[0045] The illumination system may include various types of optical components, such as refractive, reflective, magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com