Detachable electromagnetic induction heater for diameter-expanded bend-pushed large-diameter elbow

An electromagnetic induction heating and electromagnetic induction technology, which is applied in the field of metal pipe fittings manufacturing, can solve the problems affecting the pushing and shaping of the elbow, affecting the heating uniformity of the tube blank, and the large bending degree of the induction coil, etc. The effect of uneven billet and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

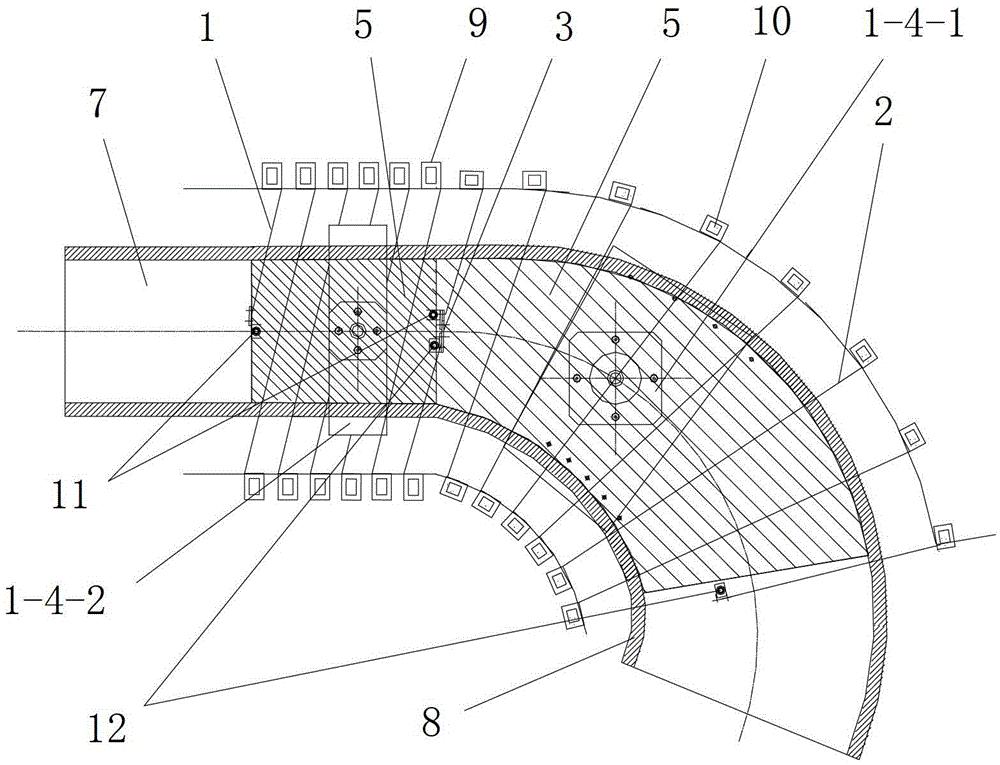

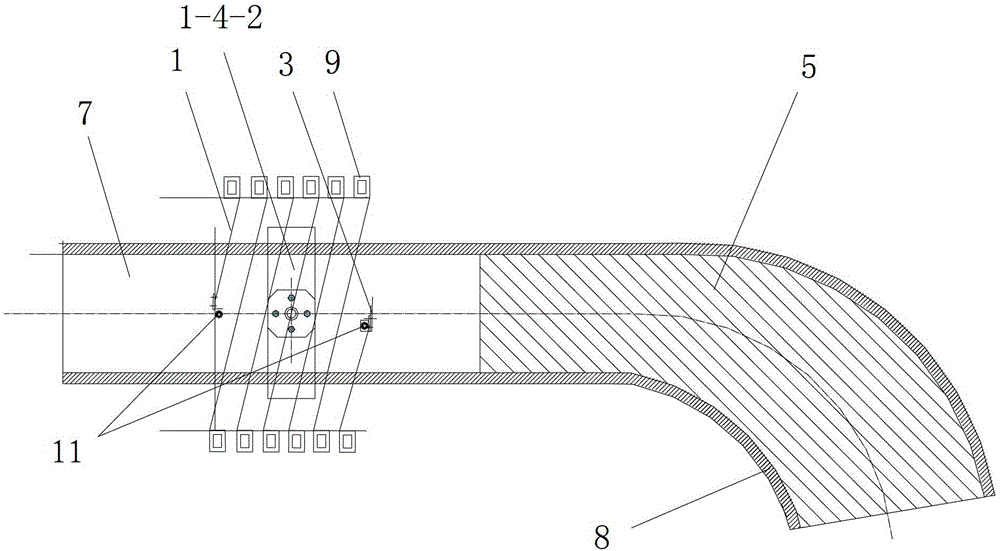

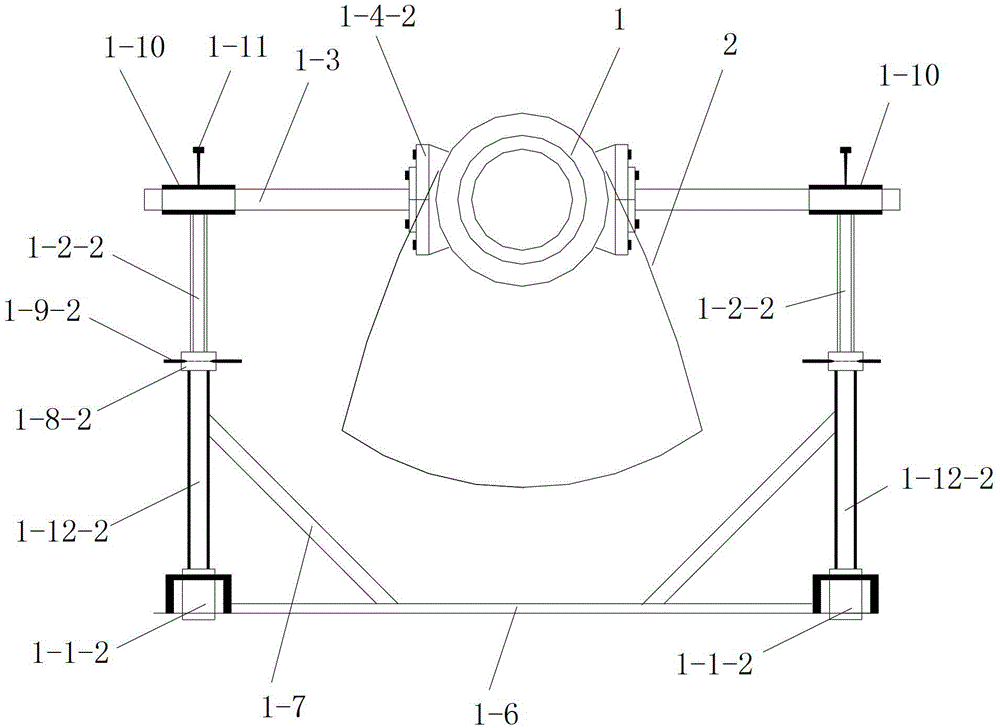

[0044] Such as figure 1 , figure 2 As shown, the present invention includes a detachable electromagnetic induction heating coil for heating and keeping warm the tube blank that needs to be formed into a large-diameter elbow 8 during the diameter expansion and push bending process. The detachable electromagnetic induction heating coil Set on the forming core head for expanding the diameter and pushing the bend, the diameter of the large-diameter elbow 8 to be formed is greater than Φ300mm. The central axis of the detachable electromagnetic induction heating coil is consistent with the central axis of the forming core, and the distance between the detachable electromagnetic induction heating coil and the forming core is greater than that of the tube blank the wall thickness. The forming core head is a croissant core head 5, and the croissant core head 5 is composed of an extension section, a deformation section and a shaping section sequentially connected, and the rear part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com