Machining method of clamshell steel-wooden desk steel member

A processing method and flip-top technology, applied in the field of student desks, can solve the problems of many assembly connectors, tight resources, and no environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

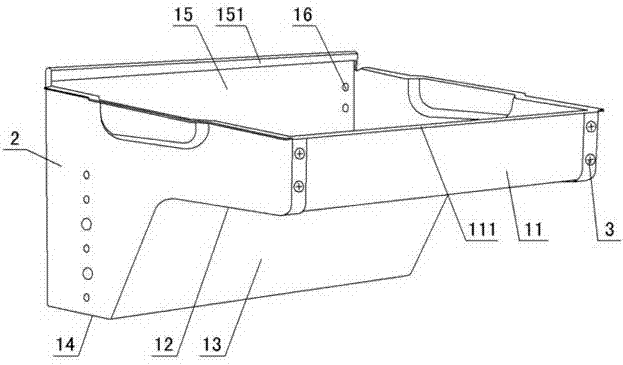

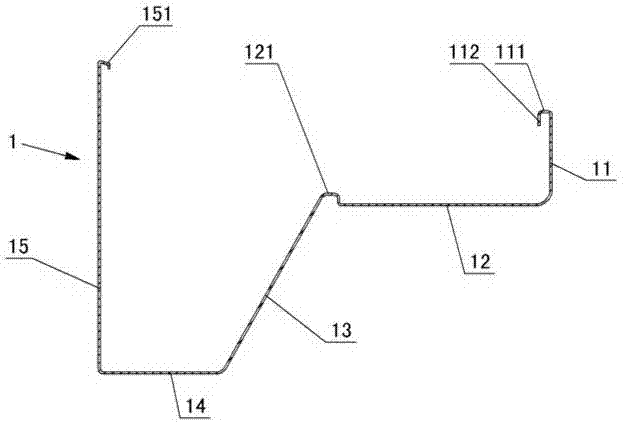

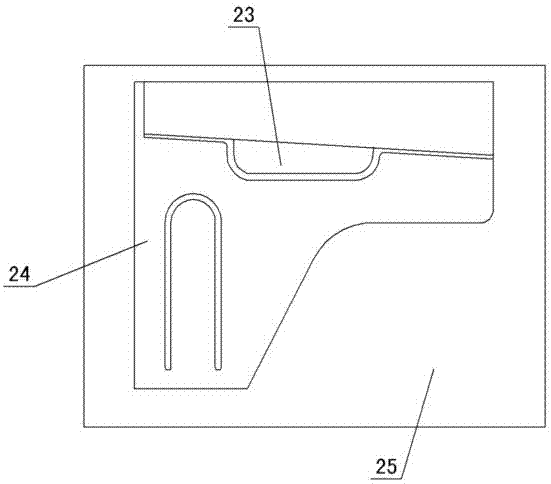

[0023] The present invention relates to a kind of processing method of the steel member of clamshell type steel-wood desk, such as figure 1 — Figure 6 As shown, it includes front cabinet boards, rear cabinet boards, left cabinet boards, right cabinet boards, inclined cabinet boards and bottom cabinet boards made of steel plates, and is characterized in that the processing method:

[0024] (1) Punching left and right cabinets: use a punching machine and a punching die to take hot-rolled steel plates, and the punching machine drives the punching dies to punch the hot-rolled steel plates into left and right cabinets to obtain left and right side panels;

[0025] (2) Punching connecting holes on the left and right cabinet panels: use a punching machine and a punching die to punch connecting holes 26 in the left and right panel sheets to obtain side panels with holes;

[0026] (3) Molding of the left and right cabinet panels: adopt a hydraulic press and a side panel forming mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com