Method for forming wood plastic section bars with polyvinyl chloride (PVC) cladding layer and extrusion mould

A technology of wood-plastic profiles and extrusion dies, which is applied in the molding of wood-plastic doors and windows main profiles and extrusion dies, which can solve the problems that different materials cannot be co-extruded and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

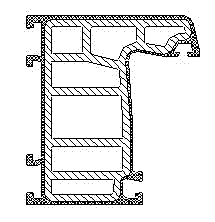

[0021] The present invention relates to a kind of molding method of the wood-plastic profile with PVC cladding layer, and the steps of this method are as follows:

[0022] Add the wood-plastic base material into the extrusion die from the feed port of the die head;

[0023] After the wood-plastic base material is added to the extrusion mold, the wood-plastic base material is extruded toward the exit of the mold through the main channel;

[0024] When the wood-plastic base material is extruded to the profile base material forming area, the PVC powder is added from the co-extrusion flow channel inlet of the extrusion die;

[0025] The PVC powder to be added and the wood-plastic base material are fused with the wood-plastic base material at the preformed flow channel on the outer wall, and then extruded from the outlet of the mold to obtain a wood-plastic profile with a PVC coating.

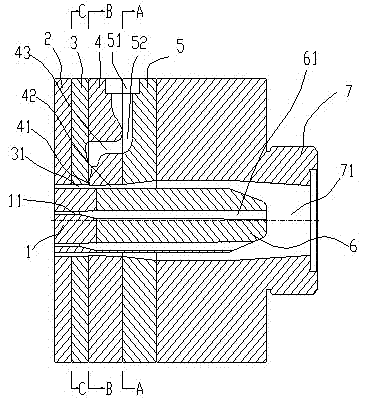

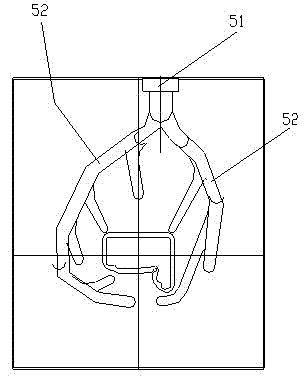

[0026] Such as figure 2 , 3 , 4, and 5, the present invention realizes the extrusion die of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com