Front upright post reinforcing structure of passenger compartment

A technology for strengthening structures and pillars, applied to superstructures, subassemblies of superstructures, vehicle components, etc., can solve problems affecting the safety of occupants in the vehicle, excessive deformation, excessive deformation and locking of doors, etc., to improve transmission and Dispersion efficiency, reduction of deformation reduction, and the effect of ensuring living space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

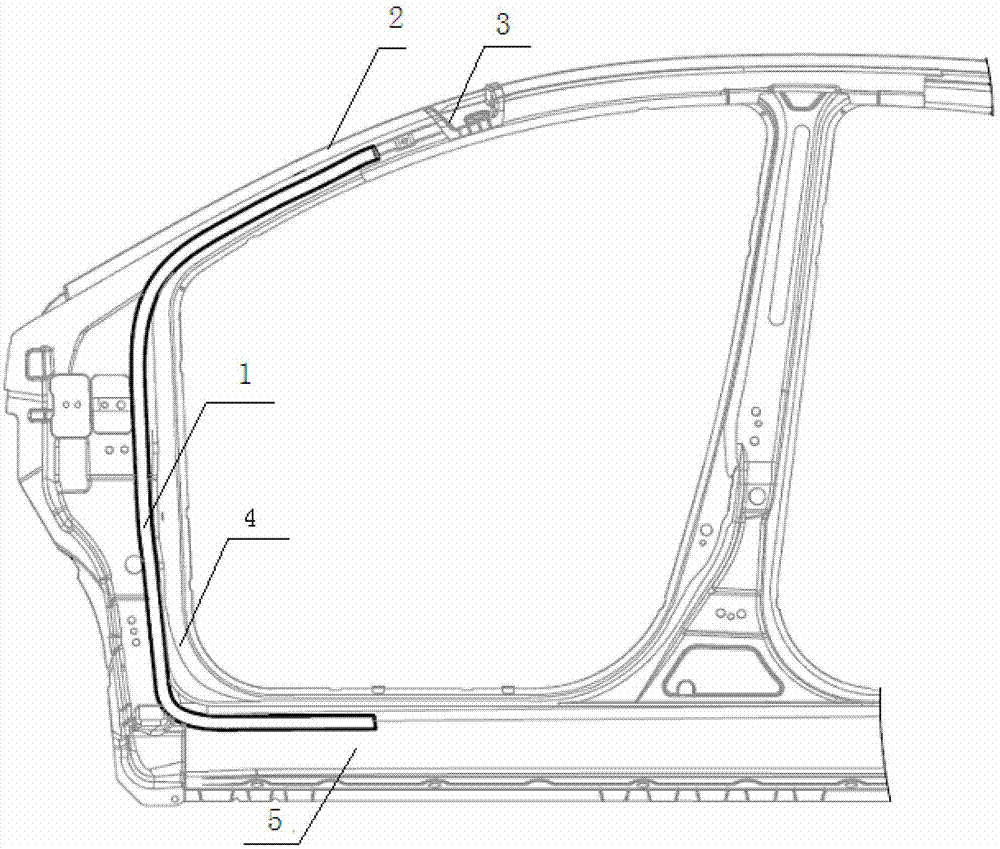

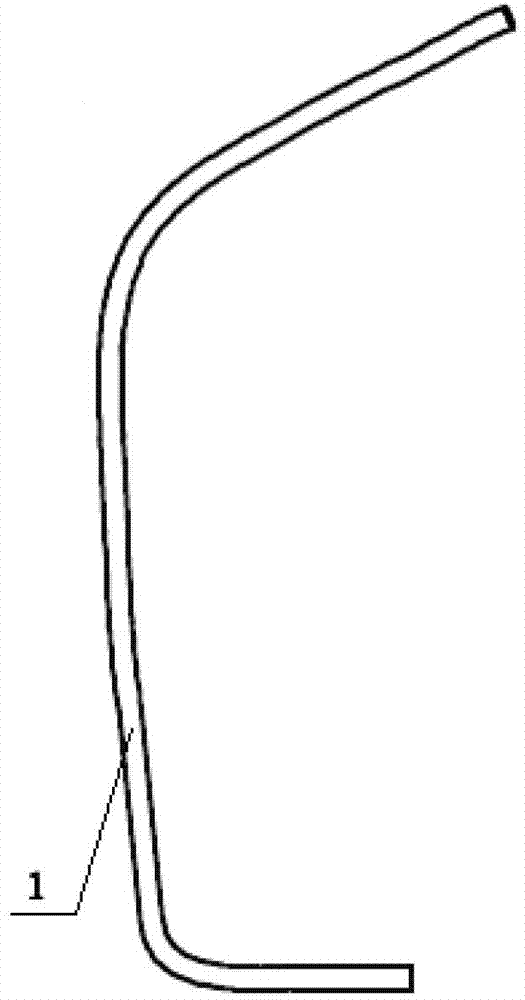

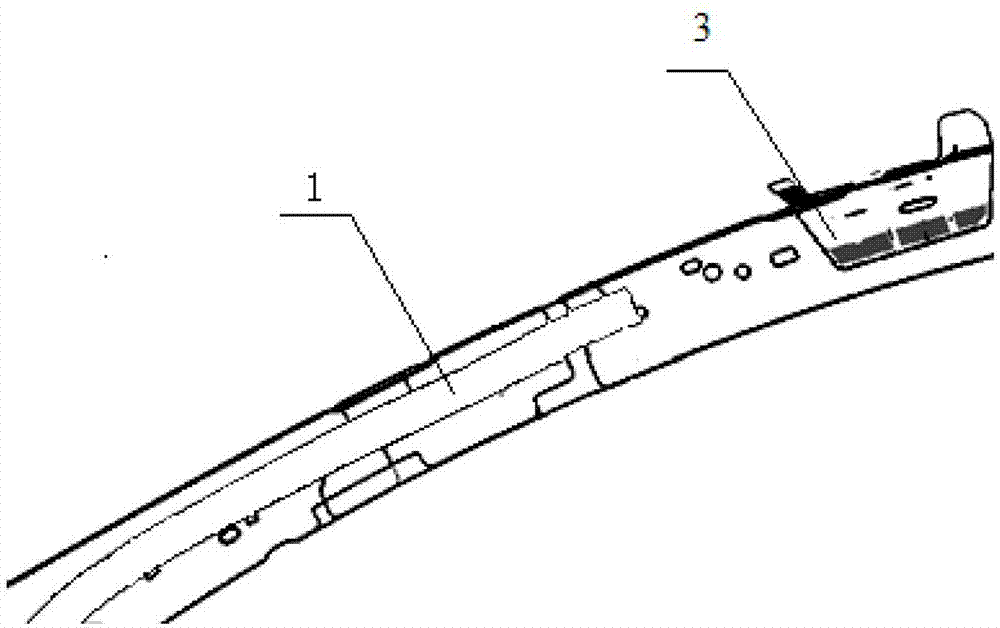

[0017] A front column reinforcement structure, comprising a reinforcement member 1 installed on the inner side of the outer panel of the side wall of the vehicle. The reinforcement member is an integrated structure, starting from the roof front cross beam 3 of the upper side beam 2 and extending along the length direction of the upper side beam 2. Extend downward and bend after passing the front pillar 4, continue to bend and extend along the length of the door sill 5 to the middle position of the door sill 5 of the front door section of the vehicle, forming a semi-enclosing state for the front door.

[0018] The front pillar reinforcement structure of the passenger compartment disclosed by the present invention effectively connects the upper structure and the lower structure of the automobile into a whole through the structure of the integral reinforcement 1, forming a semi-enclosing state for the front door, and has a great effect on the front door frame and the door. Good prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com