Telescopic machine head pressing column

A telescopic and pressure column technology, which is applied in the direction of conveyor objects, earth drilling, underground transportation, etc., can solve the problems of unfavorable safety production, collapse of pressure columns, etc., and achieve the effects of saving wood, easy operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

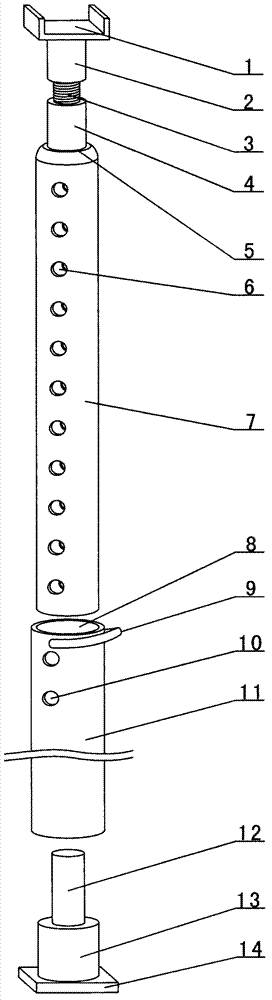

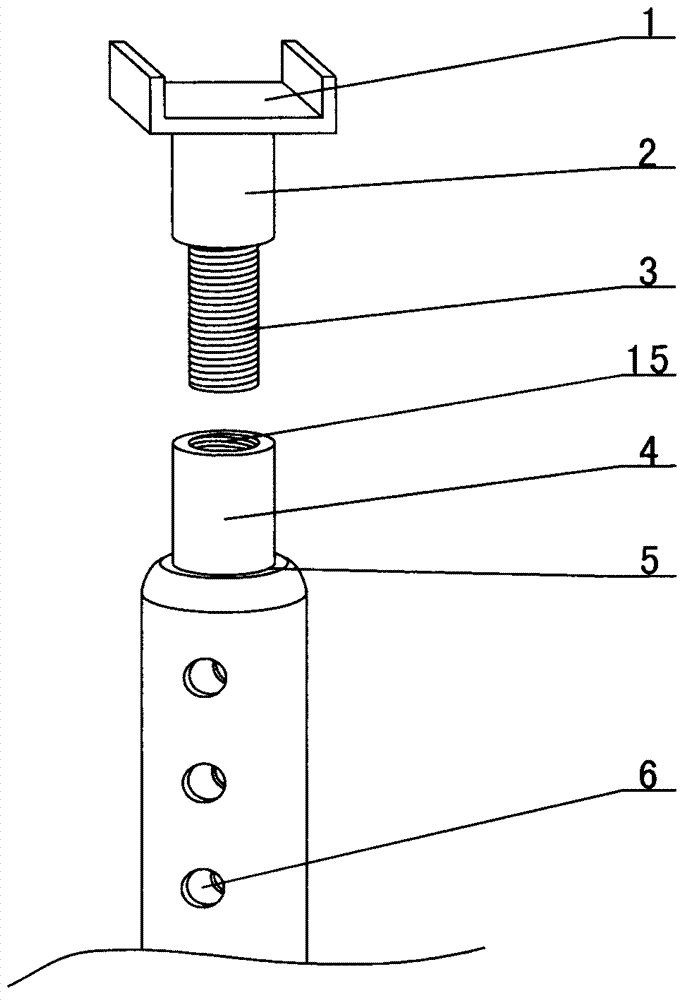

[0017] combined with figure 1 Or the telescopic head pressure column described in 2, including "U" shaped bracket 1, screw rod 3, threaded pipe 4, main support rod 7, height adjustment pipe 11, base plate 14, the upper end of screw rod 3 is connected to the steel pipe 2 At the lower end, the middle part of the bottom surface of the "U"-shaped bracket 1 is connected to the upper end of the steel pipe 2; the upper end of the main support rod 7 is provided with a threaded pipe 4, and the lower end of the threaded pipe 4 is necked and welded with the upper end of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com