Device for detecting brake performance of disk damper brake of friction type elevator

A disc brake and detection device technology, applied in elevators, brake types, mechanical equipment, etc., can solve the problem of not forming a high-precision, high-reliability, mature detection scheme and device, and achieve an effective and reliable detection scheme. The device is simple and feasible, and the control performance is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

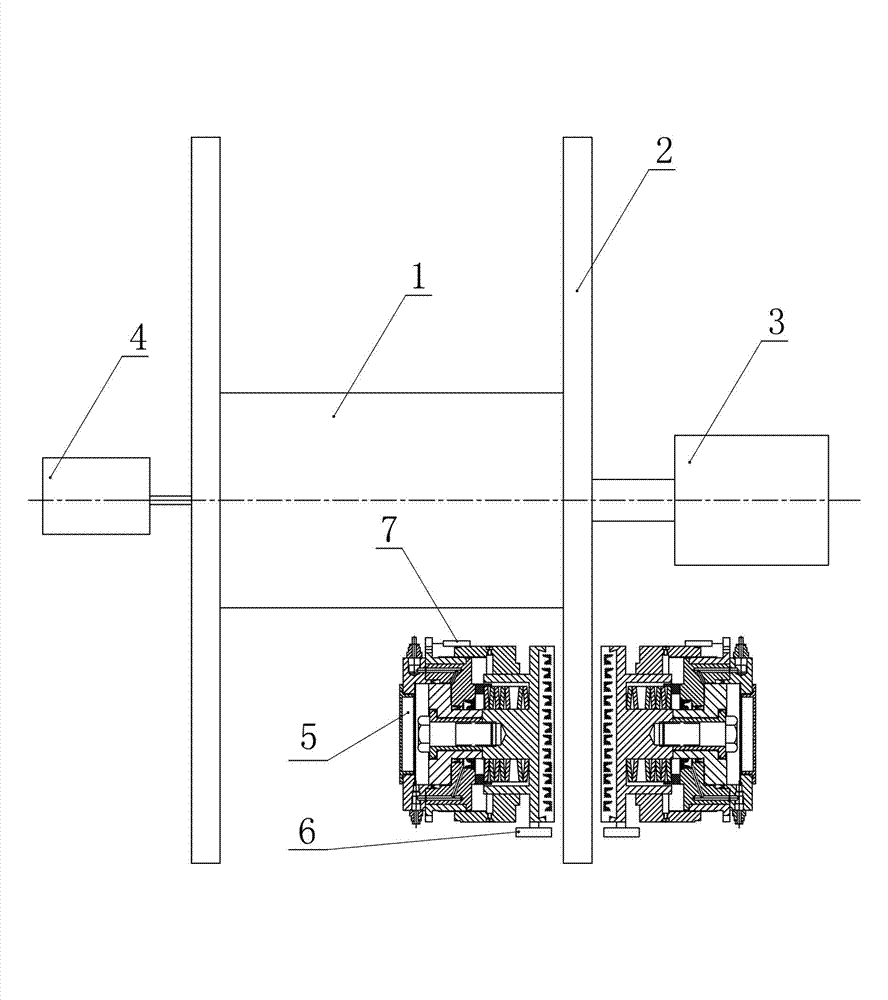

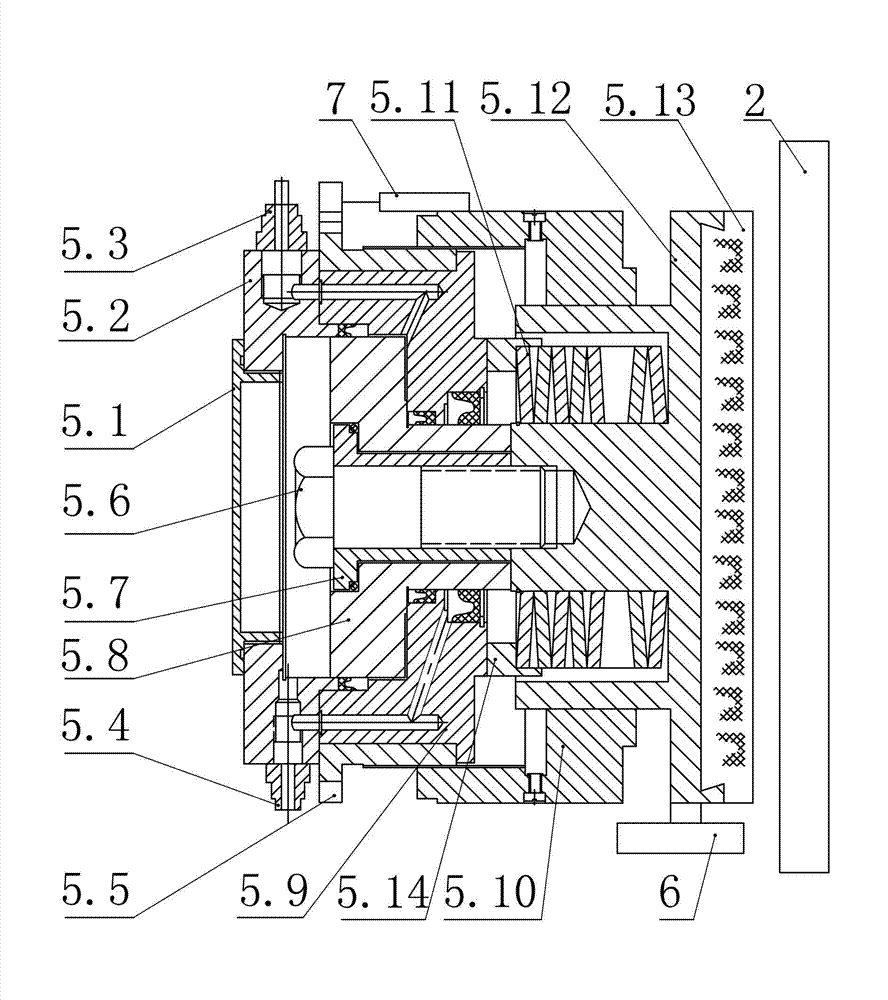

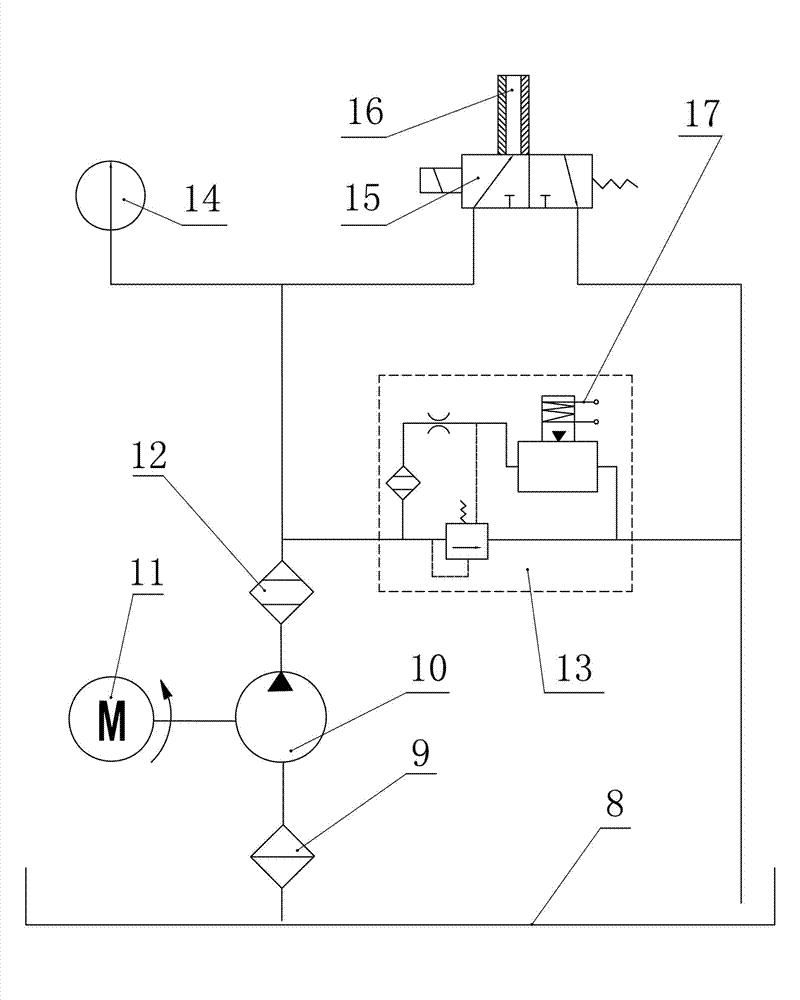

[0024] Embodiments of the present invention such as figure 1 , 2 , 3, and 4, a friction hoist disc brake braking performance detection device, including a friction drum 1 and a disc brake 5, the two ends of the friction drum 1 are provided with a brake disc 2, the system The disc brake 5 is installed on the moving disc 2, and the friction drum 1 is connected to the hoist motor 3. It is characterized in that: a speed photoelectric encoder 4 is installed on the shaft end of the friction drum 1, and the speed photoelectric encoder 4 is connected to data detection, processing and control. The programmable controller 29 in the center, the eddy current displacement sensor 6 is installed on the butterfly spring barrel 5.12 of the disc brake 5, and the end face of the eddy current displacement sensor 6 is kept the same as the end face of the brake shoe 5.13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com