Spraying device of scraper loader

A technology of spraying device and gangue rake machine, which is applied in the field of mining equipment, can solve problems such as the uneven stroke operation gap of the main and auxiliary roller mechanisms, adverse effects on the health of employees, and inflexible linkage of the gangue rake machine spray, so as to achieve flexible and reliable mechanism connection , good atomization effect and sufficient water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

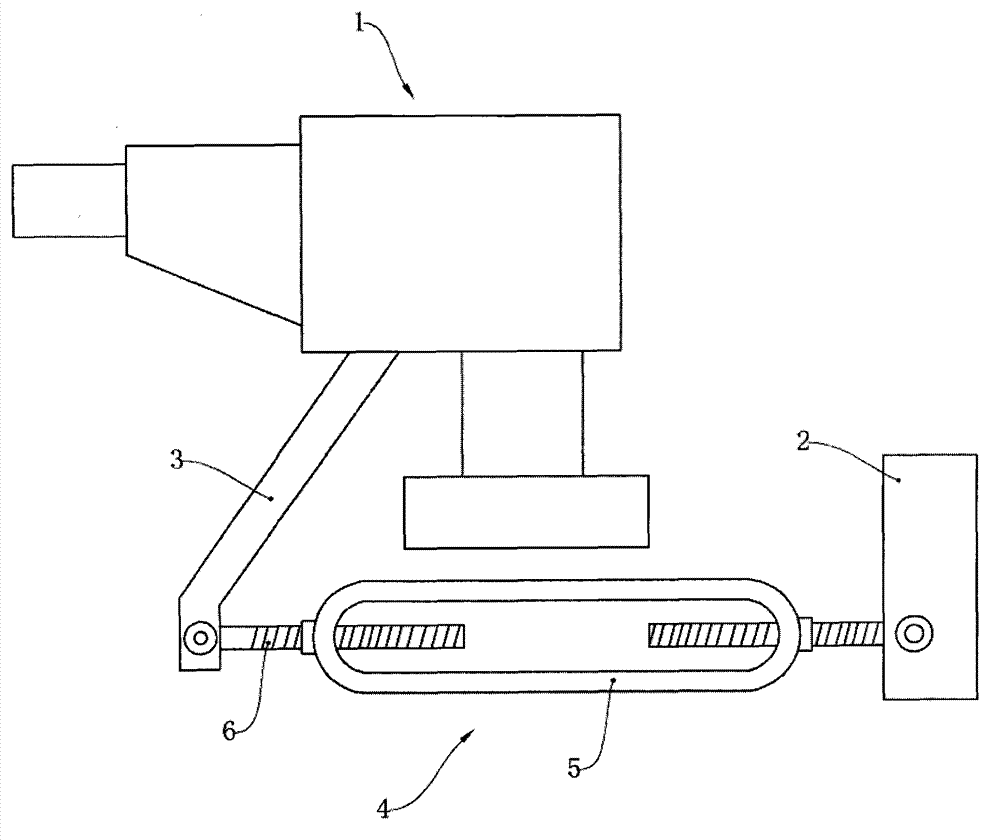

[0015] see figure 1 , a rake machine spray device, comprising a fixedly installed liquid injection gun 1, characterized in that the liquid injection gun 1 is provided with a linkage pull rod 2, and the linkage pull rod 2 is connected to the liquid injection gun by a stroke control rod 1 on the handle switch 3.

[0016] In this embodiment, the stroke control rod includes a retractable turnbuckle screw 4, and the turnbuckle screw 4 includes a threaded mounting fork 5 with bolt holes at both ends, and bolts are threaded in the two bolt holes. Columns 6, one bolt column 6 is connected with the linkage pull rod 2, and the other bolt column 6 is connected with the handle switch 3.

[0017] The basic principles and main features of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com