Pulse eddy current probe for pipeline

A technology of pulsed eddy current and pipes, which is applied in the field of detection devices for pipe wall thickness reduction, to achieve the effect of improving detection efficiency and overcoming signal fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

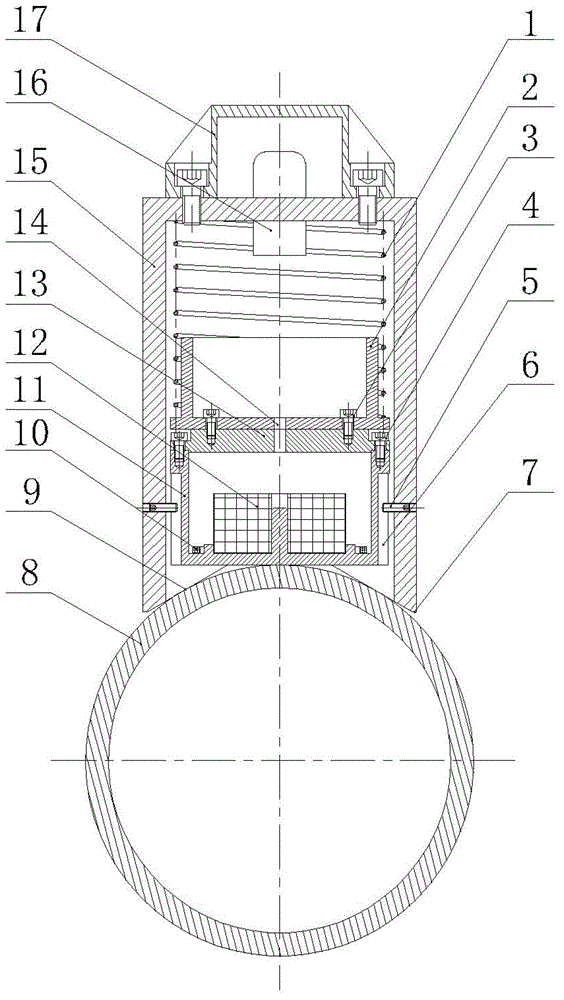

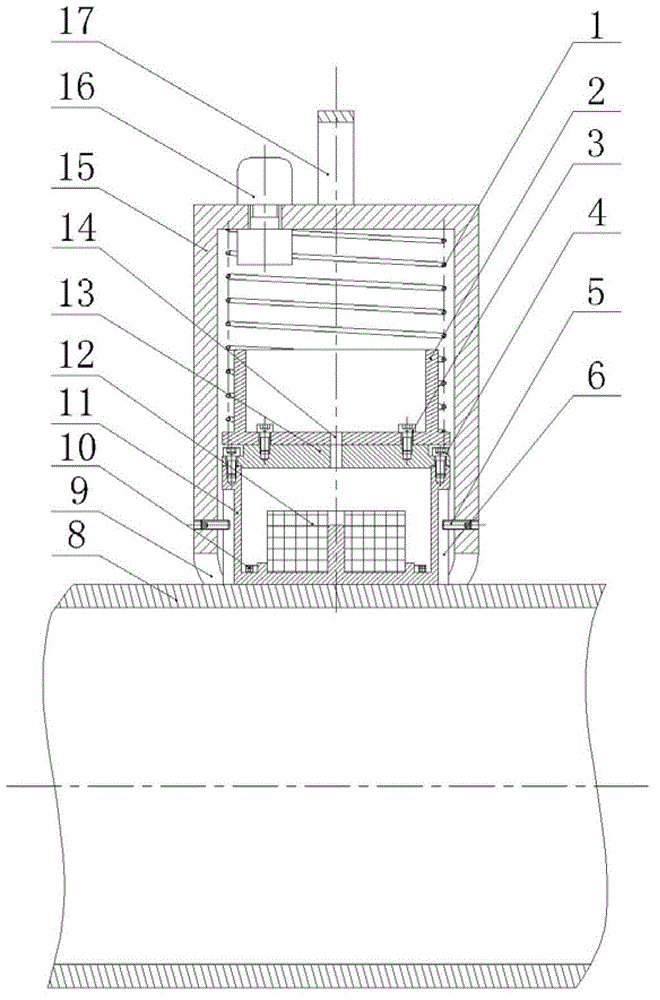

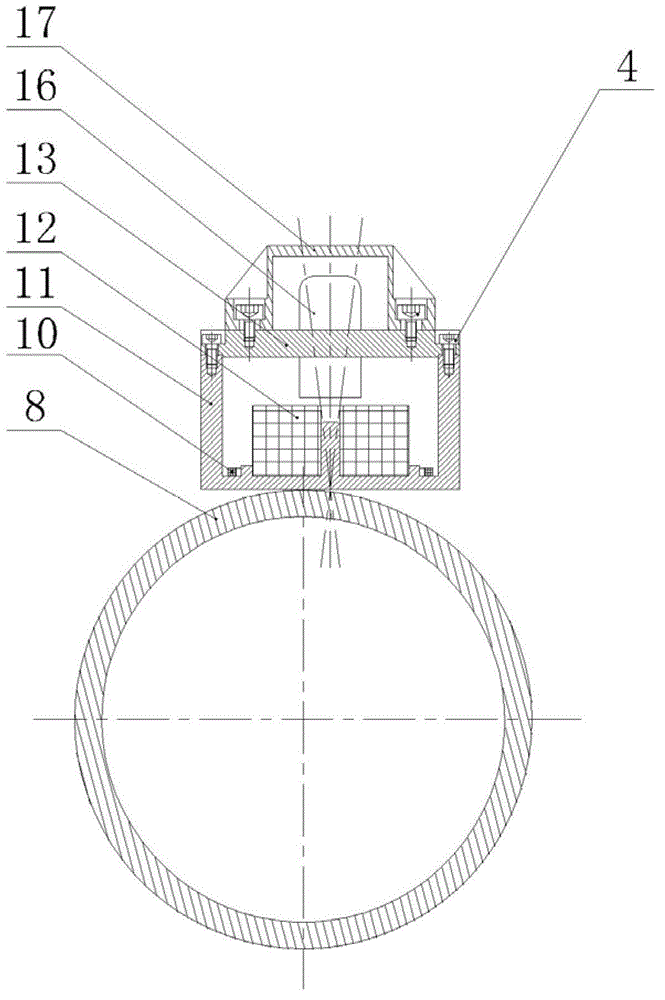

[0027] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only illustrative and do not constitute a limitation of the present invention.

[0028] figure 1 with figure 2 It is a cross-sectional view of the pulsed eddy current probe for pipeline in this embodiment when detecting the wall thickness of the pipeline. Such as figure 1 with figure 2 As shown, the pulsed eddy current probe for pipelines in this embodiment includes excitation coil 12, receiving coil 10, base 11, end cap 13, guide column 2, spring 1, shell 15, screw 3, screw 4, limit screw 5, navigation Socket 16 and handle 17.

[0029] The base 11 is in the shape of a cylinder with an open upper end and a closed lower end, and the exciting coil 12 and the receiving coil 10 are accommodated in the base 11 . Both the exciting coil 12 and the receiving coil 10 are wound into rings, the inner diameter of the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com