Prediction Method of Clay Consolidation Coefficient Based on Microstructural Parameters

A technology of consolidation coefficient and prediction method, which is applied in soil material testing, material inspection products, etc., can solve the problems of complex retention and reconstruction processes and laws, and it is difficult to reflect the relationship between the consolidation characteristics of different clays, so as to shorten the experimental time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for predicting the clay consolidation coefficient based on microstructure parameters of the present invention will be described in conjunction with the accompanying drawings.

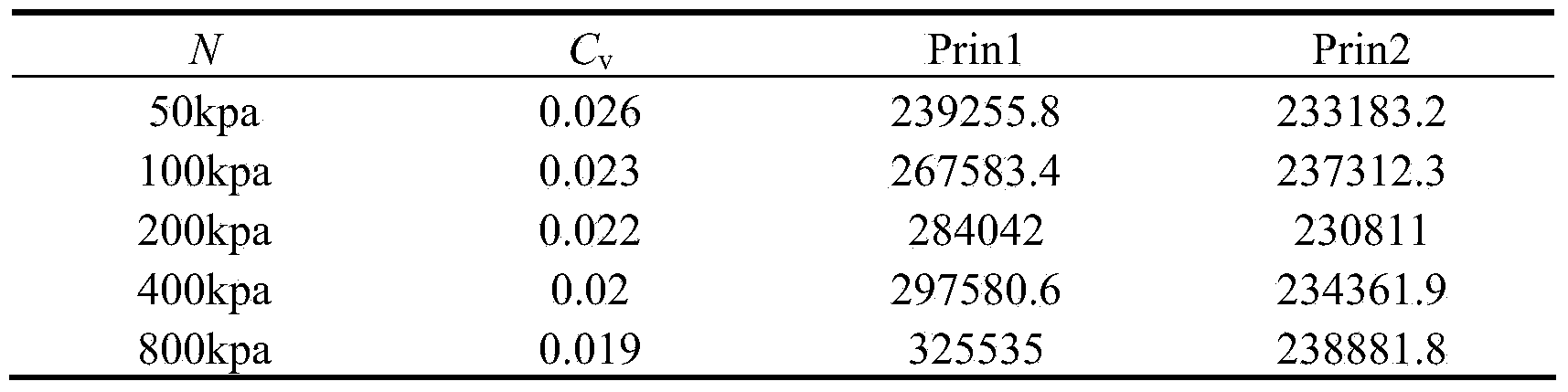

[0024] The mechanism of the clay consolidation coefficient prediction method based on microstructural parameters of the present invention is based on: on the one hand, under different pressures, the saturated density and dry density of a specific saturated clay after consolidation are different, and completely depend on the pressure ; On the other hand, under the same pressure, there are great differences in the consolidation process and consolidation results of different soils. That is to say, the consolidation of clay depends on its inherent characteristics (mineral composition, density, particle composition, pore composition, void ratio, compressive modulus, consolidation coefficient, strength index, etc.), while some inherent characteristics (density , pore composition, void ratio,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com