Fluorescent lamps having high cri and lpw

A technology of red light and blue light, applied in phosphor composition, 4:Ce3+, which can solve the problems of high CRI and inability to obtain high LPW at the same time, and achieve the effect of improving LPW

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

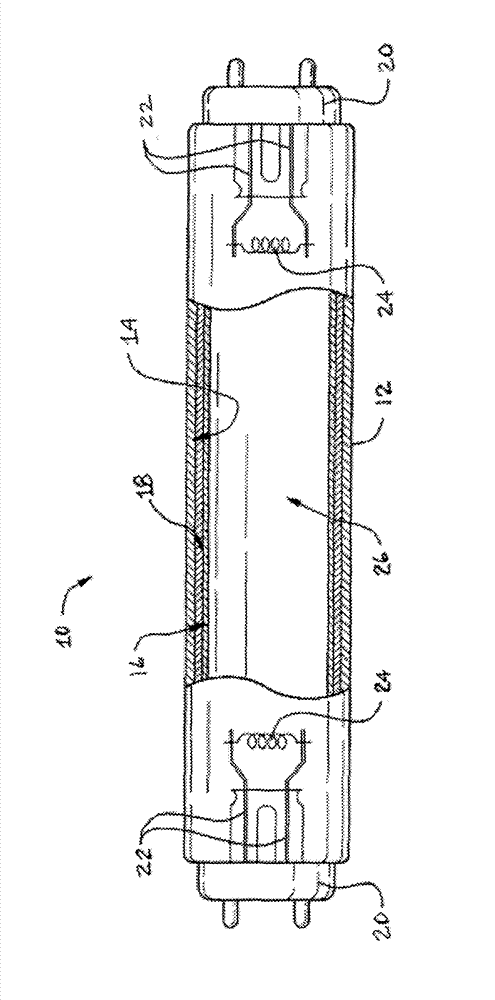

[0046] Six lamps were prepared using a phosphor mixture according to an embodiment of the invention, the mixture comprising YEO / Y 2 o 3 :Eu 2 、LAP / LaPO 4 : Ce 3+ , Tb 3+ , BAM / BaMgAl 10 o 17 :Eu 2+ and BAMn / BaMgAl 10 o 17 :Eu 2+ , Mn 2+ . The lamp is a 4100K four-pin F32T8 linear fluorescent lamp.

[0047] Table 1: YEO-LAP-BAM-BAMn phosphor system.

[0048] light number

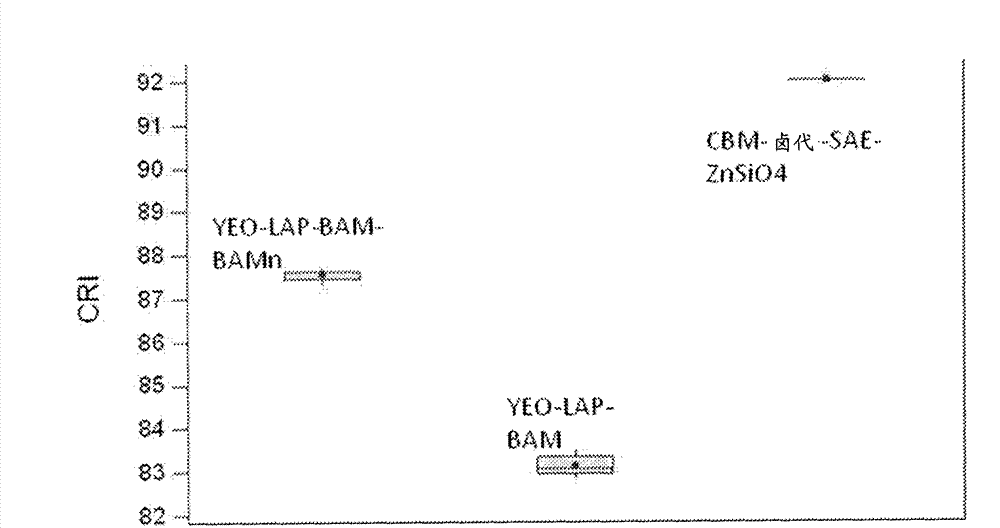

[0049] The lamp of Example 1, comprising the four-phosphor mixture according to the invention, exhibited in each case a CRI of 87 or higher and at the same time a high LPW of at least more than 86.

Embodiment 2

[0051] Using inclusive YEO / Y based on traditional lamp technology 2 o 3 :Eu 2+ (0.466 wt%), LAP / LaPO 4 : Ce 3+ , Tb 3+ (0.442 wt%) and BAM / BaMgAl 10 o 17 :Eu 2+ (0.092% by weight) of the tri-phosphor mixture also produced six lamps. The lamp is a 4100K four-pin F32T8 linear fluorescent lamp. As can be seen, the phosphor system includes the same red, green and blue phosphors as the system in Example 1. However, the blue-green phosphor of the system according to Example 1 of the present disclosure was not included.

[0052] Table 2: YEO-LAP-BAM phosphor system.

[0053] light number

[0054] The lamp of Example 2 achieves a higher LPW value than the lamp of Example 1 . However, the CRI value is lower than the expected value of 87 or higher than 87. Therefore, by comparing the data for the lamps from the phosphor coating system of Example 1 compared with this Example 2, it can be concluded that the addition of blue-green Phosphors, especially BAMn, result i...

Embodiment 3

[0056] Three lamps were prepared using four phosphor mixtures in which not all phosphors were rare earth phosphors. The mixture in this traditional phosphor system includes CBM / GdMgB5O10:Ce 3+ , Mn 2+ (3.01% by weight), halo / Ca5(PO4)3(F, Cl):Sb 3+ , Mn2+ (4.24 wt%), SAE / Sr 4 al 14 o 25 :Eu2+ (2.57% by weight) and Zn 2 SiO 4 :Mn 2+ (0.18% by weight). The lamp is a 4100K four-pin F32T8 linear fluorescent lamp.

[0057] Table 3: CBM-halo-SAE-Zn2SiO4 phosphor system.

[0058] light number

LPW

CRI

1

54.5

92.0

2

54.9

92.0

3

54.9

92.0

average

54.8

92.0

[0059] The lamps of Example 3 exhibit very low LPW values, although they do achieve very high CRI values (92).

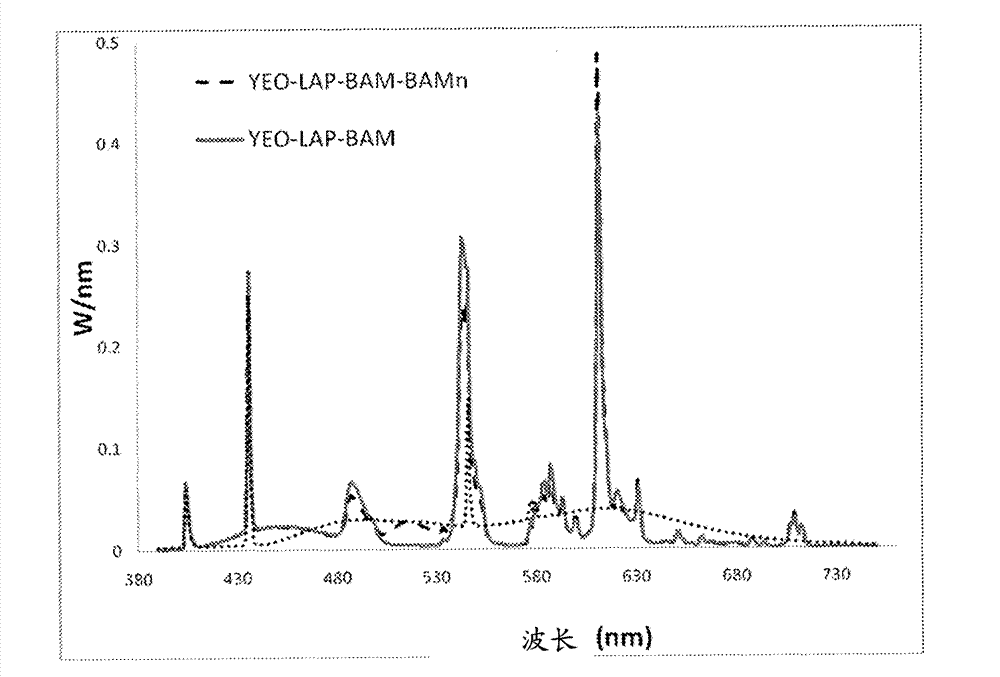

[0060] figure 2 Graphs showing the emission spectra of the respective phosphor mixtures of Examples 1, 2 and 3 are provided. The phosphor blend of Example 2, which is a known three-phosphor blend and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com